When conducting preclinical studies, selecting the appropriate feeding needle can significantly impact your research outcomes, animal welfare compliance, and operational efficiency. This comprehensive guide helps biomedical researchers, pharmaceutical laboratories, and CROs make informed decisions about oral gavage needle selection and customization.

Understanding Feeding Needles: Essential Tools for Oral Administration

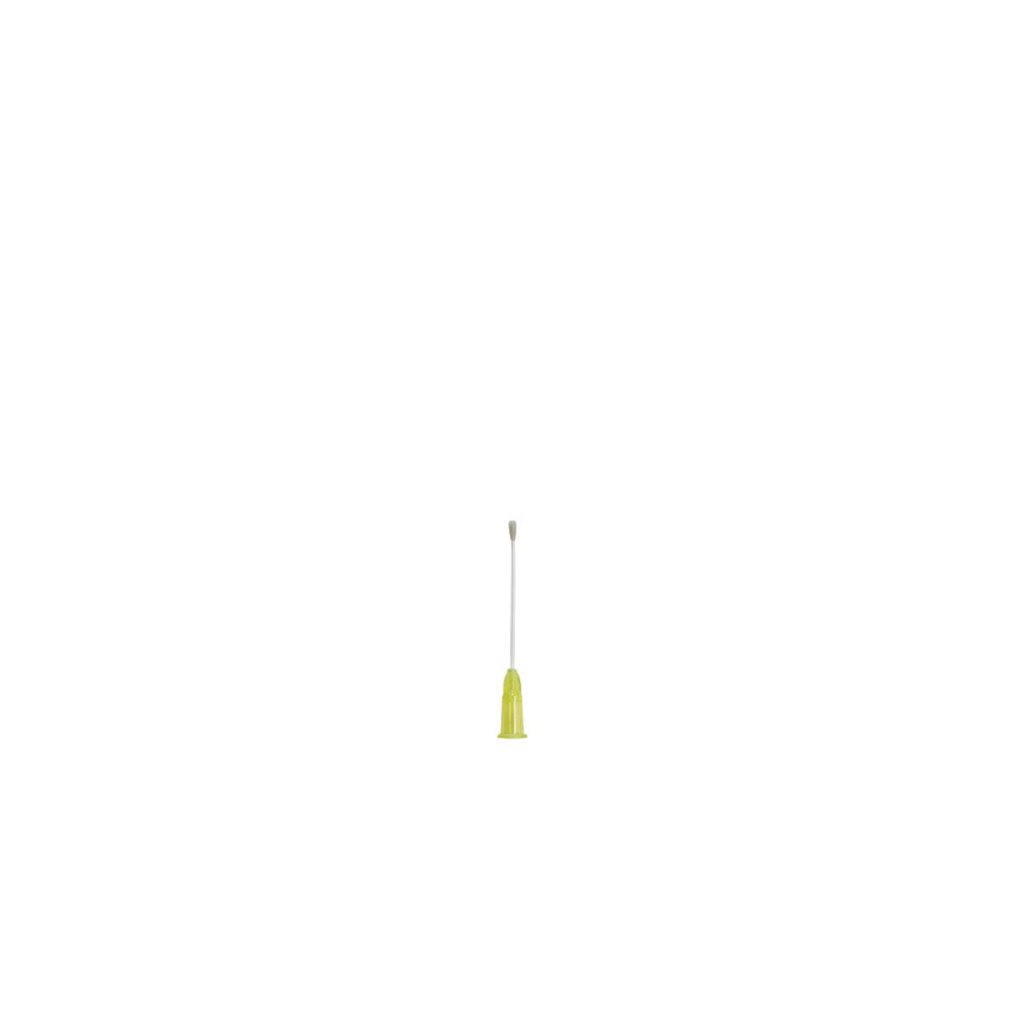

A feeding needle, also known as an oral gavage needle, is a specialized medical instrument designed for delivering precise doses of test compounds, medications, or nutritional substances directly into the stomach of laboratory animals. Unlike standard hypodermic needles, feeding needles for laboratory animals feature rounded ball tips that prevent esophageal trauma during administration.

Why Proper Gavage Needle Selection Matters

Research has shown that inappropriate needle selection contributes to 23% of oral dosing complications in laboratory settings. The right oral gavage needle ensures:

- Accurate dose delivery without compound loss or mucosal adhesion

- Reduced animal stress through smooth, trauma-free insertion

- Reproducible results across multi-year studies

- Regulatory compliance with IACUC and animal welfare standards

- Cost efficiency through optimal disposable vs. reusable selection

Disposable Gavage Needles vs. Reusable Options: Making the Right Choice

When to Choose Disposable Gavage Needles

Disposable gavage needles offer distinct advantages for specific research scenarios:

High-throughput screening studies: When dosing 50+ animals daily, disposable gavage needles eliminate cleaning time and reduce cross-contamination risks. Pharmaceutical companies conducting Phase I safety assessments typically prefer disposable options for their sterility assurance.

Infectious disease research: Studies involving pathogenic organisms require strict contamination control. Single-use feeding needles prevent inadvertent pathogen transmission between animal subjects, a critical consideration in virology and bacteriology laboratories.

Variable compound formulations: When testing different chemical entities or formulation variants, disposable gavage needles eliminate concerns about residual compound interactions that could compromise data integrity.

Advantages of Reusable Feeding Needles

Reusable oral gavage needle systems provide economic and environmental benefits:

Long-term standardized protocols: Multi-year studies with consistent dosing procedures benefit from autoclavable stainless steel feeding needles that maintain dimensional accuracy through 100+ sterilization cycles.

Budget-conscious research programs: Academic institutions and small biotech companies can reduce consumable costs by 60-75% using properly maintained reusable gavage needle sets.

Sustainability initiatives: Laboratories committed to reducing medical waste find reusable feeding needles align with green laboratory certification programs.

Critical Specifications: Gauge, Length, and Tip Design

Understanding Gauge Sizes for Different Species

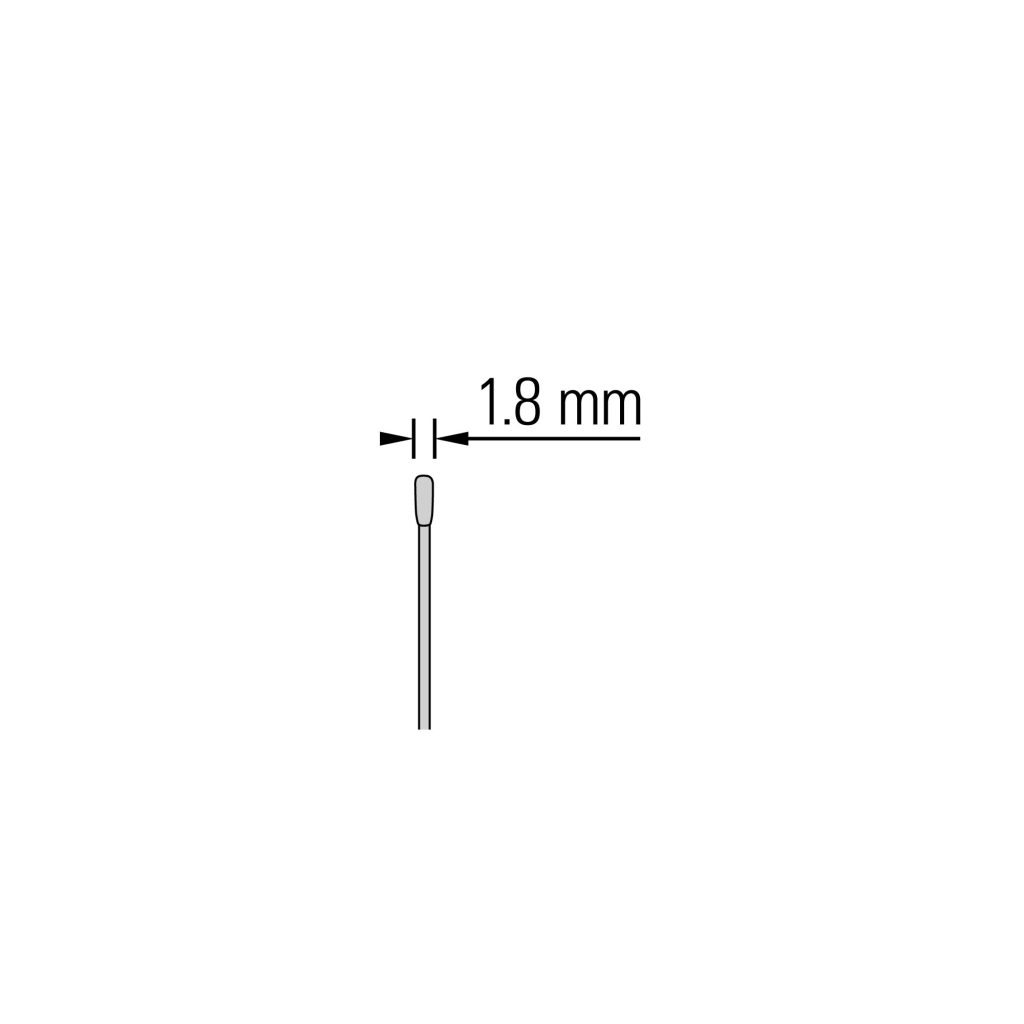

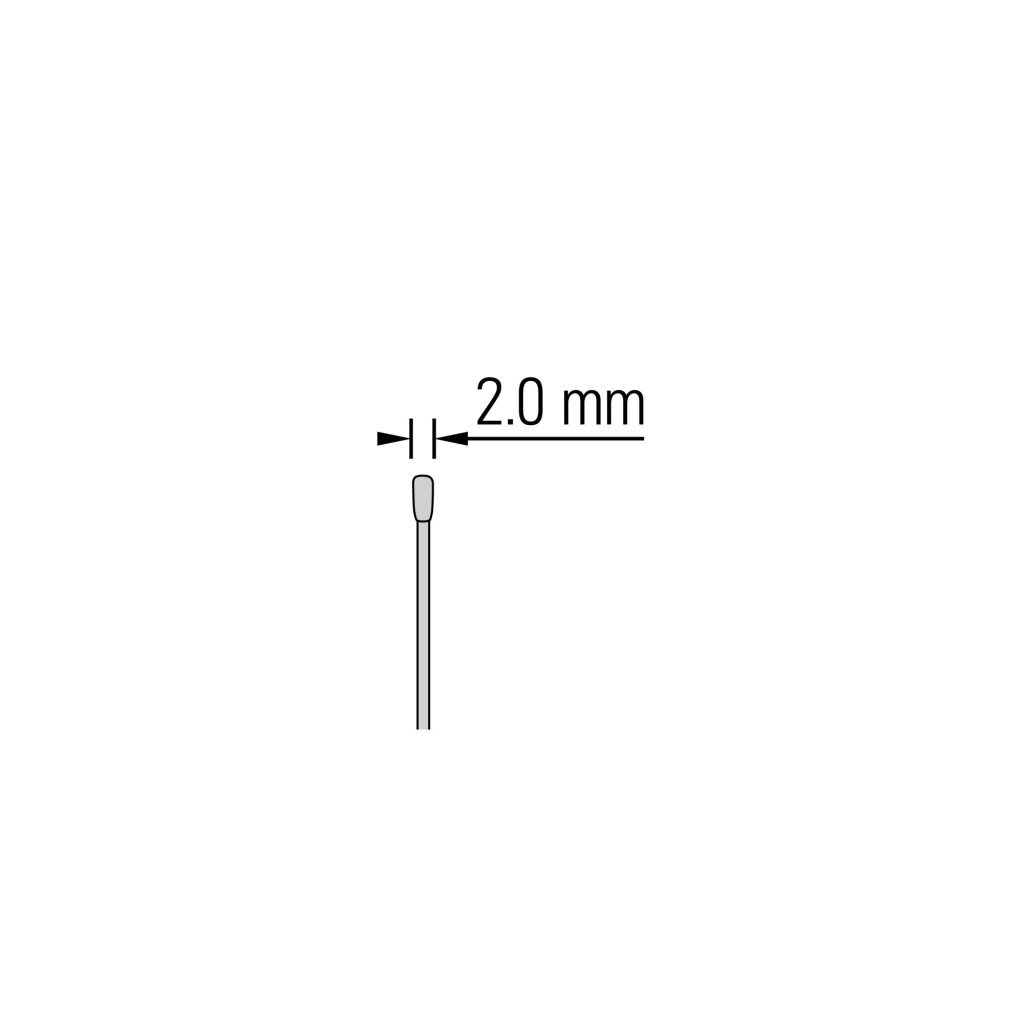

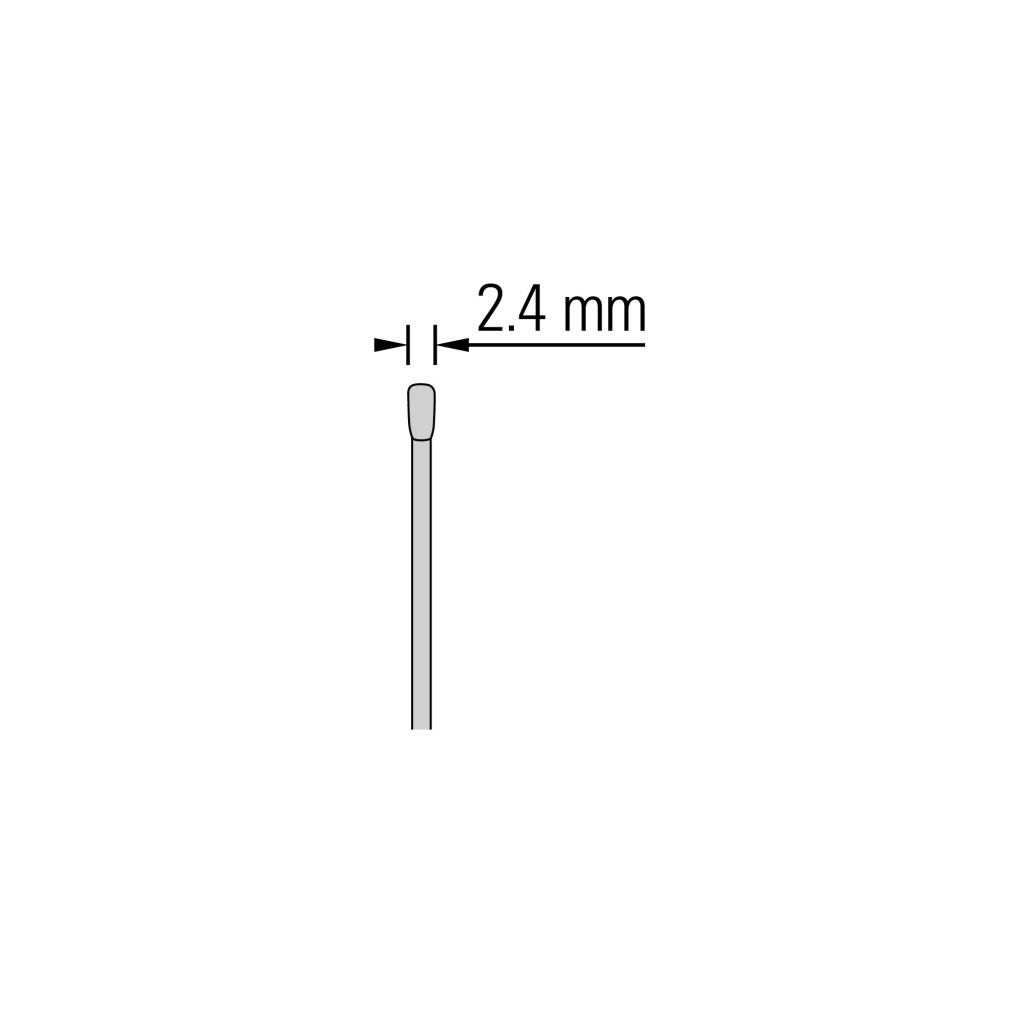

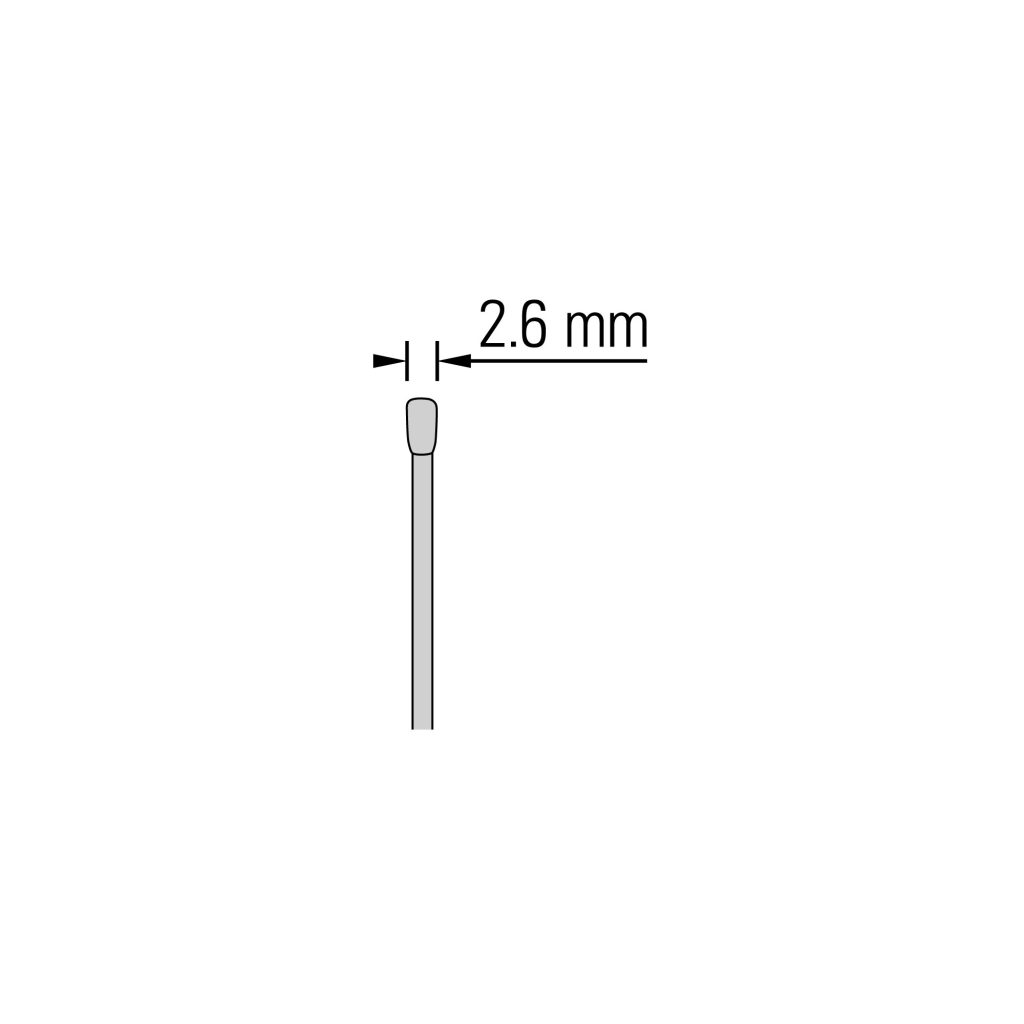

The gauge measurement determines the outer diameter of your feeding needle. Our comprehensive needle manufacturing capabilities span 16G to 34G, but oral gavage applications typically use:

- 16G feeding needles (1.65mm OD): Large rabbits, guinea pigs over 800g

- 18G oral gavage needle (1.27mm OD): Standard adult rats (250-400g), large guinea pigs

- 20G disposable gavage needles (0.90mm OD): Young adult rats (150-250g), mice over 30g

- 22G feeding needle (0.71mm OD): Adult mice (20-30g), juvenile rats

Incorrect gauge selection causes 67% of esophageal injuries reported in laboratory animal incident databases. Always verify manufacturer specifications match your animal weight ranges.

Optimal Length Selection Based on Anatomy

Feeding needle length must reach the stomach without excessive insertion depth:

- Mice (25-40mm): Standard adult mice require 38mm oral gavage needles; neonatal studies may need custom 25mm lengths

- Rats (75-100mm): Adult rat protocols typically use 75-80mm feeding needles; obese phenotype studies benefit from 100mm options

- Guinea pigs (80-100mm): Their longer esophageal anatomy demands careful length matching

- Rabbits (100-150mm): Larger breeds require custom-length solutions

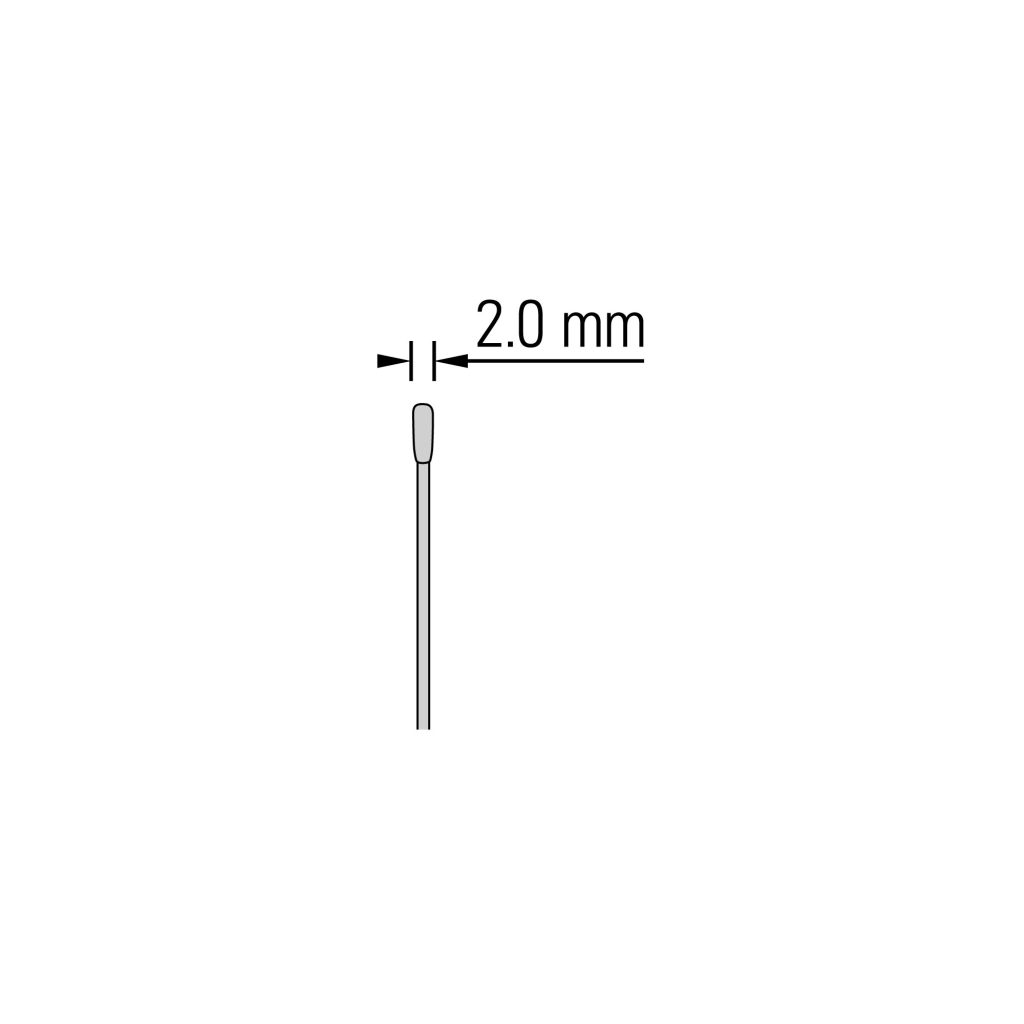

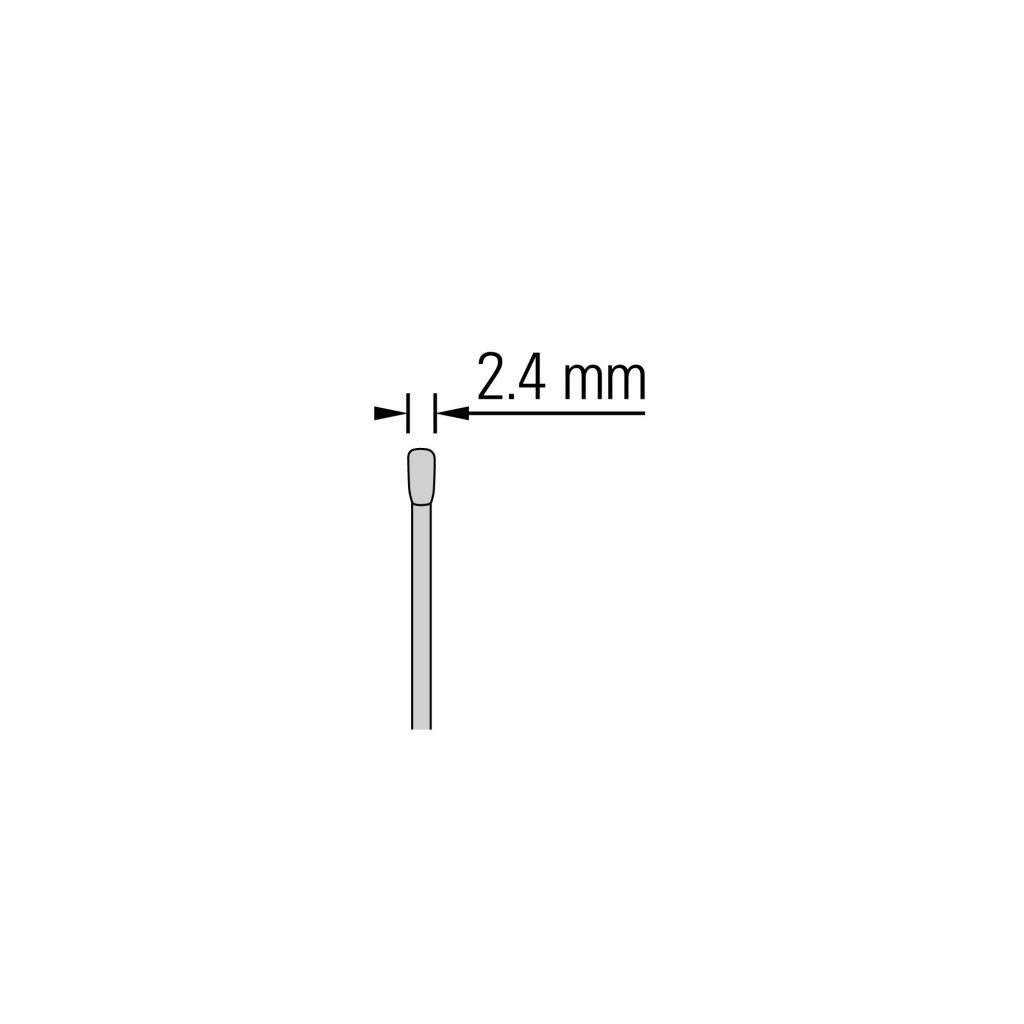

Ball Tip Design: The Critical Safety Feature

The rounded ball tip distinguishes oral gavage needles from standard needles. Precision-manufactured tips should measure 1.5-2.0× the shaft diameter, creating smooth transitions that guide past the epiglottis without tissue damage. Our specialized needle products undergo optical inspection ensuring tip symmetry within ±0.03mm tolerances.

Custom Solutions for Specialized Research Needs

When Standard Feeding Needles Fall Short

Research protocols often present unique challenges requiring customized disposable gavage needles or modified reusable systems:

Difficult-to-dose animal models: Genetically modified mice with craniofacial abnormalities may require modified tip geometries. Our engineering team collaborates with researchers to design custom feeding needle profiles that accommodate anatomical variations.

Viscous formulation delivery: Suspensions or oil-based vehicles need enlarged internal bore diameters. Standard oral gavage needle designs may cause pressure buildup; custom bore specifications ensure smooth flow without tip blockage.

Volume-verified dosing: GLP toxicology studies benefit from laser-etched volumetric markings on feeding needles, enabling visual confirmation of dose delivery without additional measurement steps.

OEM Customization Process

Our custom needle manufacturing services follow a structured development pathway:

- Specification consultation: Define gauge, length, tip design, and material requirements

- Prototype development: Receive sample disposable gavage needles within 7-10 business days

- In vivo validation: Test prototypes in your animal facility under actual protocol conditions

- Dimensional verification: Request metrology reports confirming all critical measurements

- Production scaling: Move to bulk orders with lot-to-lot consistency guarantees

Minimum order quantities start at 1,000 units for custom feeding needles, with volume pricing at 5,000+ units.

Quality Assurance and Regulatory Compliance

Manufacturing Standards That Matter

ISO 13485 certification ensures every oral gavage needle meets medical device quality management standards. Critical control points include:

- Material verification: Medical-grade 304 stainless steel composition analysis

- Dimensional inspection: Automated optical measurement of gauge, length, and tip geometry

- Surface finish testing: Roughness analysis ensuring <0.4μm Ra for mucosal contact surfaces

- Sterility validation: Gamma irradiation or ETO sterilization for disposable gavage needles

- Biocompatibility testing: USP Class VI certification for tissue contact safety

Documentation for Regulatory Submissions

When feeding needles become part of IND submissions or regulatory toxicology studies, comprehensive documentation proves essential:

- Certificates of Analysis with dimensional data

- Material Safety Data Sheets (MSDS)

- ISO certificates and manufacturing site documentation

- Sterilization validation reports for disposable options

- Traceability records linking lot numbers to production dates

Best Practices for Feeding Needle Administration

Technique Optimization to Minimize Complications

Even premium oral gavage needles require proper technique:

Pre-procedure preparation: Measure dosing volume accurately; pre-fill the feeding needle to eliminate air bubbles that could cause gastric distension.

Animal positioning: Vertical restraint with gentle neck extension creates straight esophageal alignment, reducing insertion resistance. Never force a disposable gavage needle past resistance points.

Insertion verification: Palpate the needle through the cervical esophagus; if resistance occurs before reaching the stomach landmark, withdraw and reposition before dosing.

Post-administration monitoring: Observe for 2-3 minutes after gavage to detect immediate complications like respiratory distress or regurgitation.

Maintenance of Reusable Feeding Needles

Proper care extends the lifespan of reusable oral gavage needle systems:

- Immediate flushing: Rinse with distilled water immediately after use to prevent protein buildup

- Ultrasonic cleaning: 10-minute cycles remove residual compounds from internal bores

- Inspection protocol: Examine tips under magnification every 20 uses; retire needles showing tip deformation

- Autoclave parameters: 121°C for 20 minutes; avoid rapid cooling that may warp precision tips

- Storage conditions: Store vertically in protective cases to prevent tip damage

Cost Analysis: Disposable vs. Reusable Economics

Breaking Down the True Cost Per Dose

A 500-animal chronic toxicity study illustrates the economic comparison:

Disposable gavage needle scenario:

- Daily dosing for 90 days = 45,000 doses

- Disposable gavage needles at $0.45/unit = $20,250

- No labor for cleaning/sterilization

- Zero equipment investment

- Total cost: $20,250

Reusable feeding needle scenario:

- Initial investment: 20 oral gavage needles at $12/unit = $240

- Autoclave costs: $0.15/cycle × 90 cycles = $13.50

- Technician cleaning time: 5 min/day × 90 days × $25/hr = $187.50

- Replacement needles (10% loss): 2 units = $24

- Total cost: $465

The reusable approach saves $19,785 for this single study—a 97.7% cost reduction.

Volume Discount Strategies

Institutional contracts for feeding needles unlock additional savings:

- 5,000-9,999 units: 15% discount on disposable gavage needles

- 10,000-24,999 units: 25% discount plus custom packaging options

- 25,000+ units: 35% discount with consignment inventory programs

Annual purchasing agreements for mixed needle products often achieve 40%+ savings compared to per-study ordering.

Troubleshooting Common Feeding Needle Challenges

Issue: Frequent Tip Deformation

Symptom: Ball tips showing flattening or asymmetry after minimal use

Root causes:

- Improper autoclave cooling (thermal shock warping)

- Excessive insertion force against bony structures

- Using oral gavage needles beyond recommended lifespan

Solutions: Implement gradual cooling protocols; retrain staff on anatomical landmarks; establish mandatory retirement schedules based on usage counts rather than visual inspection alone.

Issue: Inconsistent Dose Delivery

Symptom: Variable compound recovery from stomach contents

Root causes:

- Feeding needle internal bore adhesion reducing flow

- Air bubbles in dosing syringes

- Incorrect needle length causing esophageal deposition

Solutions: Switch to custom needles with enlarged bores for viscous compounds; implement pre-fill protocols eliminating air; verify needle length matches current animal weights.

Issue: Animal Mortality During Gavage

Symptom: Respiratory distress or death following oral administration

Root causes:

- Tracheal intubation with disposable gavage needles

- Esophageal perforation from excessive force

- Aspiration of regurgitated dose

Solutions: Mandatory competency assessments for all dosing personnel; implement real-time supervision for first 50 procedures; consider alternative routes if mortality exceeds 0.5%.

Emerging Trends in Feeding Needle Technology

Micro-Volume Gavage Needles

Neonatal and juvenile animal studies increasingly demand feeding needles capable of delivering 10-50μL volumes accurately. Recent innovations include:

- Ultra-fine 25G-27G oral gavage needle designs for mouse pups

- Integrated volume stops preventing over-insertion

- Low-dead-volume tips minimizing compound waste

Radiopaque Feeding Needles

Pharmacokinetic studies requiring dose placement verification now utilize disposable gavage needles with radiopaque markers, enabling fluoroscopic confirmation of gastric delivery without endpoint necropsy.

Ergonomic Handle Designs

Repetitive strain injuries affect 31% of technicians performing high-volume gavage procedures. Next-generation reusable feeding needle systems incorporate:

- Contoured grips reducing hand fatigue

- Integrated depth guides for consistent insertion

- Quick-connect Luer locks expediting syringe changes

Selecting Your Feeding Needle Supplier: Key Considerations

Manufacturing Capability Assessment

Not all oral gavage needle suppliers offer equivalent capabilities. Evaluate potential partners on:

Customization flexibility: Can they modify tip geometries, lengths, and bore diameters? Our custom manufacturing services accommodate specifications from initial concept through validation.

Quality documentation: Request Certificates of Analysis, dimensional inspection reports, and material certifications before committing to large orders of disposable gavage needles.

Technical support: Suppliers should provide administration training, troubleshooting guidance, and protocol optimization consultations—not just product catalogs.

Supply chain reliability: Verify inventory depth and production capacity. A supplier unable to fulfill urgent orders for feeding needles can derail time-sensitive research timelines.

Building Long-Term Partnerships

Successful research programs benefit from collaborative supplier relationships:

- Annual needs assessment meetings optimizing your oral gavage needle inventory

- Consignment programs maintaining ready access to critical sizes

- Priority production slots for urgent custom feeding needle projects

- Volume commitment discounts reducing per-study consumable costs

Conclusion: Precision Tools for Precision Research

The right feeding needle selection represents more than a procurement decision—it’s a commitment to research quality, animal welfare, and operational excellence. Whether your laboratory requires standard disposable gavage needles for routine toxicology studies or custom-engineered solutions for specialized animal models, thoughtful selection pays dividends through:

- Enhanced data quality from consistent dose delivery

- Reduced protocol deviations and animal losses

- Improved regulatory inspection outcomes

- Long-term cost optimization through strategic sourcing

As biomedical research grows increasingly sophisticated, the humble oral gavage needle remains an indispensable tool connecting innovative compounds with therapeutic discovery. Invest in quality, customize for your needs, and partner with suppliers who understand that every feeding needle represents a step toward advancing human and animal health.

Ready to optimize your oral gavage protocols? Explore our complete range of laboratory needles or contact our technical team for custom feeding needle consultations. With over 15 years of precision manufacturing experience, we transform challenging dosing requirements into reliable research tools.

Key Takeaways

✅ Gauge selection determines successful administration across different animal species and weights

✅ Disposable gavage needles excel in high-throughput and contamination-sensitive studies

✅ Reusable feeding needles offer 95%+ cost savings for long-term standardized protocols

✅ Custom solutions address unique anatomical challenges and viscous formulation delivery

✅ Ball tip precision within ±0.03mm prevents 67% of reported esophageal injuries

✅ Proper technique matters as much as equipment quality for reproducible outcomes

✅ Supplier partnerships providing technical support and documentation strengthen regulatory compliance