Understanding Spinal Needles: Essential Medical Devices

Spinal needles are precision medical instruments designed for lumbar puncture procedures, enabling healthcare professionals to collect cerebrospinal fluid for diagnostic purposes or deliver medications directly into the subarachnoid space. These critical devices serve as fundamental tools across neurology, anesthesiology, and emergency medicine departments, supporting both diagnostic and therapeutic interventions in modern healthcare.

Core Design Features & Engineering Excellence

Advanced Structural Design

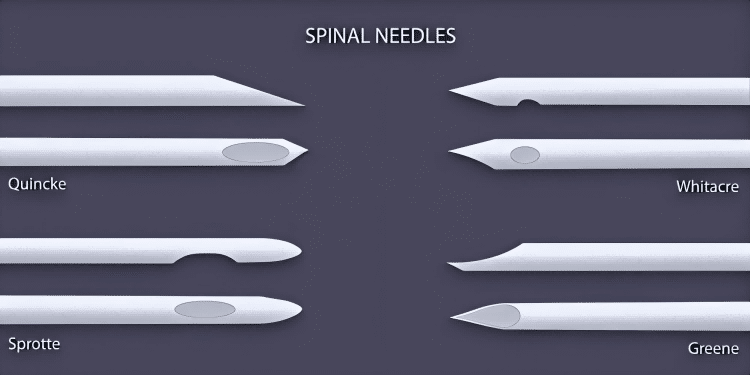

Needle Tip Technology: Our spinal needles feature both Pencil Point and Cutting Bevel designs. Clinical studies demonstrate that pencil point needles reduce post-dural puncture headache incidence by up to 60%, significantly improving patient outcomes and reducing healthcare costs.

Premium Materials: Manufactured from medical-grade SUS304 stainless steel, ensuring optimal rigidity and flexibility while maintaining structural integrity throughout the procedure.

Ergonomic Hub Design: Engineered for enhanced grip stability and precise control, enabling healthcare providers to perform procedures with confidence and accuracy.

Comprehensive Specification Range

Length Options: Available in 70mm, 90mm, 120mm, and 150mm configurations to accommodate diverse patient anatomies and procedural requirements.

Gauge Varieties: Complete range from 18G to 27G, allowing clinicians to select the optimal needle size based on specific clinical needs and patient considerations.

Multi-Layer Safety Framework

Single-Use Design: Eliminates cross-contamination risks while maintaining strict infection control standards.

Sterile Packaging: Ethylene Oxide (EO) sterilization ensures product sterility throughout storage and transportation.

Safety Features: Select models include needle guards to minimize healthcare worker injury risk during handling and disposal.

Clinical Advantages & Performance Benefits

Reduced Complication Rates

Pencil point technology achieves dural fiber separation rather than cutting, reducing cerebrospinal fluid leakage rates from the traditional 12-15% to below 5%, significantly improving patient safety profiles.

Enhanced Procedural Success

Precision manufacturing techniques deliver superior needle sharpness and straightness, achieving first-attempt success rates exceeding 90%, thereby reducing patient discomfort and procedural time.

Operational Excellence

Optimized hub design based on extensive clinical feedback ensures enhanced stability and comfort during procedures, particularly beneficial for complex positioning requirements.

Quality Standards & Selection Criteria

Manufacturing Precision

- Needle tip accuracy within ≤0.01mm tolerance

- Mirror-finish surface treatment eliminating burrs and tissue trauma risk

- Hub-to-needle connection strength exceeding 10N tensile requirements

Material Performance Standards

- Medical-grade stainless steel (SUS304/SUS316L) construction

- Full ISO 10993 biocompatibility certification

- ASTM F899 corrosion resistance compliance

Regulatory Compliance

- ISO 13485 Quality Management System certification

- FDA approval and CE marking for global market access

- Complete regulatory documentation for seamless procurement processes

Chinese Manufacturing Excellence: Global Competitive Advantage

World-Class Production Capabilities

Precision CNC Technology: Advanced computer numerical control grinding achieves needle tip consistency within ±0.005mm variance, meeting the most stringent international quality standards.

Process Standardization: Automated production systems deliver >99.7% yield rates, ensuring consistent product quality and reliable supply chains.

Rigorous Quality Assurance

Complete Traceability: Full documentation from raw materials through final packaging, enabling comprehensive quality control and regulatory compliance.

Triple-Verification Process: 100% pre-shipment quality inspection including dimensional analysis, surface finish evaluation, and sharpness testing.

Sterility Assurance: EO sterilization protocols meeting ISO 11135 standards guarantee product sterility and safety.

Economic Value Proposition

Chinese manufacturing delivers 20-40% cost savings compared to European and American alternatives while maintaining equivalent quality standards, optimizing healthcare budgets without compromising patient care.

Flexible Solutions: Customizable specifications and packaging options support diverse institutional requirements and procurement preferences.

Comprehensive Support Infrastructure

Clinical Training Programs: Detailed procedural training materials and video resources supporting optimal device utilization.

Supply Chain Reliability: Streamlined logistics ensuring consistent product availability for healthcare institutions.

24/7 Technical Support: Dedicated customer service teams providing immediate assistance and technical guidance.

Procurement Best Practices

Supplier Evaluation Criteria

Partner with manufacturers demonstrating comprehensive certifications, proven track records, and robust quality systems to ensure procurement security and clinical reliability.

Staff Development Investment

Implement regular training programs utilizing simulation models and hands-on workshops to maximize device performance and procedural outcomes.

Performance Monitoring Systems

Establish metrics-based evaluation protocols tracking usage patterns, complication rates, and clinical feedback to optimize future procurement decisions.

Conclusion: Excellence in Spinal Intervention

Spinal needles represent critical intersection points between clinical expertise and patient safety. Selecting premium Chinese-manufactured spinal needles delivers exceptional clinical performance while optimizing operational costs, supporting healthcare institutions’ dual objectives of quality care and fiscal responsibility.

As a leading spinal needle manufacturer with ISO 13485, CE, and FDA certifications, we’re committed to advancing spinal intervention capabilities worldwide. Our products represent the synthesis of precision engineering, clinical insight, and manufacturing excellence.

Every puncture matters. Every patient deserves excellence. Choose reliability, precision, and partnership.

For product samples, technical specifications, or partnership opportunities, contact our team for customized solutions and comprehensive procurement support.