Understanding needle specifications

Why Needle Size Matters More Than You Think

Picture this: A diabetic patient needs to inject insulin 3-4 times daily. If the needle size is too large, every injection becomes unnecessarily painful. Meanwhile, in an emergency room, a trauma surgeon needs to rapidly transfuse blood for a hemorrhaging patient—too small a needle size could mean the difference between life and death. This is why selecting the right needle size isn’t just about comfort; it’s about optimal patient outcomes.

As a leading needle factory with over two decades of manufacturing excellence, Kohope understands that every millimeter and every gauge specification carries weight. We specialize in custom needle solutions spanning human healthcare, veterinary medicine, aesthetic procedures, and beyond—helping medical institutions worldwide find their perfect custom needle match.

Understanding Needle Specifications: Decoding the Gauge System

Before diving into applications, let’s clarify a counterintuitive aspect of needle size: the gauge system works in reverse. Higher gauge numbers mean thinner needle sizes, while lower numbers indicate larger diameters. A 32G insulin needle size is hair-thin, whereas a 14G trauma needle size is comparatively robust.

Medical needle gauges typically range from 7G to 34G, with lengths spanning 6mm to 150mm. Understanding this inverse relationship is crucial for selecting appropriate custom needles from any professional needle factory for specific medical applications.

Human Healthcare Applications: Precision for Every Procedure

Insulin Needles: Daily Companions for Diabetes Management

With over 400 million diabetics globally, insulin needles represent one of the most widely used medical devices. These ultra-fine needle sizes typically feature 29G-32G specifications with lengths from 4mm to 12.7mm.

Real-World Application: Sarah, a Type 1 diabetic, uses 31G × 6mm needle size for her daily subcutaneous injections. This precise needle size provides virtually painless administration in her abdomen. Her 12-year-old son Michael, recently diagnosed, requires 32G × 4mm needle size—the shorter length prevents accidental intramuscular injection in children with less subcutaneous fat.

For larger body types, 8mm or 12.7mm needle sizes ensure accurate subcutaneous delivery. Our needle factory can produce custom needles with specialized bevel angles (typically 30-45 degrees) and apply medical-grade silicone coating that reduces penetration resistance by 50%, significantly minimizing patient discomfort. These custom needle specifications are designed specifically for diabetic care.

Beauty & Aesthetic Needles: Precision Engineering for Cosmetic Excellence

The aesthetic medicine industry demands exceptional needle size precision—millimeter differences in injection depth directly impact cosmetic outcomes.

Microneedling/Mesotherapy: Utilizing 30G-34G ultra-fine needle sizes at 4mm-13mm lengths, these specialized custom needles deliver hyaluronic acid, vitamins, and nutrients to the superficial dermis. At premium aesthetic clinics, practitioners use 32G × 13mm needle size for skin boosters, precisely controlling injection depth to achieve radiant, hydrated skin without bruising.

Dermal Filler Injections: Requiring 25G-30G needle sizes at 13mm-38mm lengths for deeper dermal or subcutaneous placement. Kohope’s needle factory produces specialized custom needle designs including blunt-tip cannulas—the rounded cannula tip gently displaces blood vessels rather than puncturing them, dramatically reducing bruising risk and improving patient satisfaction.

Botulinum Toxin Administration: Employing 30G-32G × 12mm needle size specifications, these precision custom needles must accurately reach facial muscle layers. Our needle factory ensures precise depth control—too shallow or too deep compromises treatment efficacy for wrinkle reduction and facial slimming.

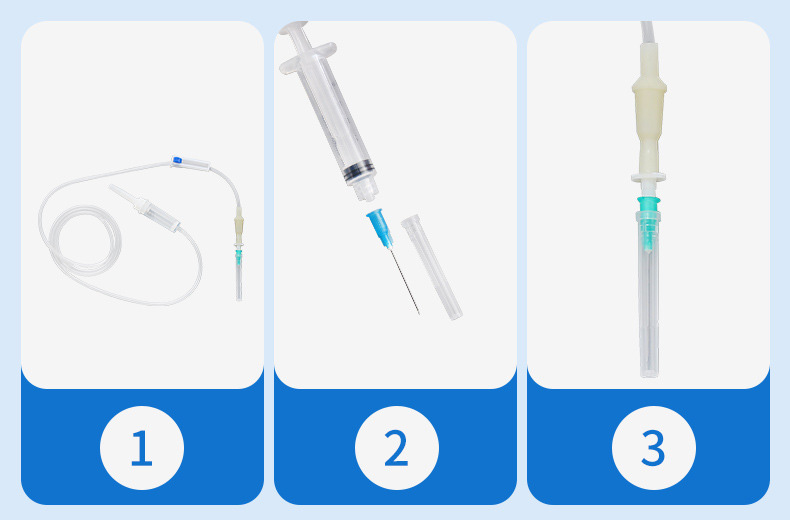

IV Needles: Lifelines in Critical Care

Intravenous needle size selection directly impacts treatment efficiency and patient comfort across diverse clinical scenarios.

Emergency Trauma: When paramedics transport a vehicle accident victim with severe hemorrhage, ER physicians immediately establish IV access using 14G or 16G large-bore needle sizes. While initial insertion may cause brief discomfort, these needle sizes enable rapid blood and fluid administration during golden-hour resuscitation—speed saves lives.

Routine Infusion Therapy: For 70-year-old Mr. Johnson hospitalized with pneumonia, nurses select 22G × 25mm needle size. This needle size provides adequate flow rates while minimizing vascular trauma in elderly patients with fragile veins—proper needle size selection is crucial for geriatric care.

Pediatric IV Access: Pediatric wards primarily use 24G-26G fine needle sizes. For 5-year-old Emma’s fever treatment, nurses employ 24G × 19mm butterfly needle size—the smaller needle size reduces fear and pain while the shorter length enhances safety in small veins.

Chemotherapy Patients: Long-term chemotherapy patients often have compromised vascular integrity, requiring 26G ultra-fine needle sizes paired with expert technique to minimize vessel damage while ensuring successful cannulation.

Intramuscular Injection Needles: Deep Tissue Drug Delivery

Intramuscular (IM) administration requires needle size specifications tailored to injection sites and patient demographics.

Adult Vaccination: COVID-19, influenza, and other vaccines typically use 23G × 25mm needle size for deltoid (upper arm) injection. This needle size adequately penetrates skin and subcutaneous tissue to reach muscle. Mass vaccination centers rely on standardized needle sizes manufactured by professional needle factory facilities to ensure efficiency and safety across thousands of daily administrations.

Antibiotic IM Injection: Penicillin and similar antibiotics often require 21G-22G × 38mm needle sizes for gluteal muscle injection. This site’s substantial muscle mass accommodates larger drug volumes, while the longer needle size ensures deep muscle penetration, preventing subcutaneous drug accumulation and subsequent induration.

Pediatric Immunization: Pediatric practices use 25G × 16mm short needle sizes. For newborn hepatitis B vaccination, physicians select even finer 27G × 16mm needle sizes for vastus lateralis (thigh) injection—gentler on delicate infant tissue.

Subcutaneous Injection Needles: Gentle Delivery to Shallow Tissue

Subcutaneous injection delivers medication between skin and muscle layers, ideal for drugs requiring gradual absorption.

Vaccine Administration: Measles, varicella, and other vaccines utilize 25G-27G × 16mm needle sizes for upper arm or anterior thigh subcutaneous injection. Community health centers stock these needle sizes in highest volumes during annual pediatric immunization campaigns.

Heparin Prophylaxis: Post-surgical thrombosis prevention requires 25G-27G × 16mm needle sizes for twice-daily abdominal subcutaneous injection. After Mr. Chen’s hip replacement, nurses trained his wife in home administration—fine needle sizes made safe self-injection feasible for family caregivers.

Phlebotomy Needles: The Foundation of Accurate Diagnosis

Proper blood collection depends on appropriate needle size selection for specimen quality and patient comfort.

Routine Health Screening: Medical centers use 21G needle size with vacuum blood collection systems—this gauge rapidly draws sufficient blood volume without causing significant hemolysis. During annual physical examination seasons, hospitals collect thousands of specimens daily using standardized 21G needle sizes for efficiency.

Special Populations: Hematology departments often use 23G needle sizes for chemotherapy patients with poor vascular access, as finer needle sizes improve puncture success rates. Neonatal screening requires 25G micro-sampling needle sizes for heel-stick collection—just a few drops enable multiple diagnostic tests.

Arterial Blood Gas: ICU arterial blood gas analysis requires physicians to use 22G-25G × 25mm specialized arterial needle sizes for radial artery puncture—demanding both sharp design and skilled technique for accurate sampling.

Veterinary Medicine: Specialized Custom Needle Solutions

Veterinary medicine represents a rapidly growing market with dramatically diverse needle size requirements across species.

Canine Injections: Size-Specific Specifications

Small Breed Care: When veterinarians vaccinate a 3kg Chihuahua, they select 25G × 16mm needle size for subcutaneous injection. Small breeds have minimal subcutaneous fat—excessively long or thick needle sizes risk penetrating to muscle layer, causing unnecessary pain. Toy Poodles, Bichon Frises, and similar breeds typically require 25G-27G fine needle sizes.

Large Breed Treatment: A 40kg Golden Retriever with hip arthritis receives anti-inflammatory medication via 20G × 38mm needle size for gluteal intramuscular injection. Large breeds possess substantial muscle mass and thicker skin, necessitating larger, longer needle sizes for effective drug administration. German Shepherds, Labrador Retrievers, and similar breeds commonly use 20G-22G specifications.

IV Catheterization: Veterinary hospitals establish pre-surgical IV access using 22G × 25mm catheter needle size for medium-sized dogs. Single insertion enables continuous fluid and medication administration throughout surgery, eliminating repeated venipuncture trauma.

Feline Medicine: Delicate Handling Required

Cats possess thinner, more sensitive skin than dogs, demanding especially gentle needle size specifications.

Feline Vaccination: For orange tabby “Marmalade’s” annual vaccines, veterinarians use 25G × 16mm needle size for scruff subcutaneous injection. Cats’ loose scruff skin forms a natural “tent” when lifted—fine needle sizes enable rapid injection with minimal feline resistance.

Feline Fluid Therapy: Senior cats with chronic kidney disease require regular subcutaneous fluid supplementation using 22G × 19mm needle size. Once owners master home administration, biweekly subcutaneous fluids dramatically improve quality of life while avoiding frequent clinic-visit stress.

Exotic Pets: Precision Custom Needle Design

Avian Species: Parrots, macaws, and other ornamental birds require 27G-30G × 12mm ultra-fine needle sizes. Birds possess delicate vessels and hollow bones—oversized needle sizes risk serious injury. Exotic veterinary practices stock specialized custom needles manufactured by experienced needle factory specialists for these unique patients.

Reptilian Medicine: Pet snakes, lizards, and other reptiles have scale-protected skin requiring 25G-27G sharp needle sizes paired with specialized technique. These custom needles feature specially designed bevel angles that more easily penetrate scales.

Equine & Livestock: Horse farms and agricultural operations use entirely different needle size specifications. Equine vaccination or treatment demands 14G-18G × 50mm or longer reinforced needle sizes. These heavy-duty custom needles feature harder materials that penetrate horses’ thick skin and muscle without bending.

Kohope Needle Factory: Custom Needle Manufacturing Excellence

As a professional needle factory with ISO 13485 certification, Kohope delivers not only standard needle sizes but also precision custom needle solutions tailored to exact client requirements.

Precision Manufacturing Technology

Our needle factory employs German-imported precision grinding equipment ensuring every custom needle’s inner diameter, outer diameter, and length maintain tolerances within ±0.05mm. This means a 100,000-unit batch demonstrates exceptional dimensional consistency—healthcare professionals experience no needle size specification variance affecting procedures.

Advanced Coating Technologies for Custom Needles

Silicone Coating: Medical-grade silicone oil coating dramatically reduces penetration resistance in our custom needles. Clinical testing reveals coated needles reduce insertion force by 50% compared to standard needles—patients report significantly diminished pain. This custom needle technology particularly benefits diabetics requiring frequent injections and aesthetic applications.

Lubricious Coating: Our needle factory applies biocompatible lubricant materials to custom needles that not only reduce discomfort but also protect vascular endothelium. Especially valuable for chemotherapy and dialysis patients requiring repeated venipuncture.

Antimicrobial Coating: Silver-ion or alternative antimicrobial agents applied to custom needle surfaces effectively reduce injection-site infection risk—ideal for immunocompromised patient populations.

Needle Tip Design Artistry in Custom Needle Production

Custom needle tip configuration appears simple yet involves sophisticated engineering. Our needle factory customizes different tip designs for specific applications:

Lancet Point: The most common tip design suitable for routine intramuscular and subcutaneous injection—minimal penetration resistance and tissue trauma in our custom needles.

Short Bevel: Smaller bevel angle ideal for intradermal injection like tuberculin testing. This custom needle design facilitates medication retention in dermal layers, forming standard wheals.

Long Bevel: Larger bevel angle particularly suited for IV cannulation. Long bevel custom needle design enhances vessel entry success, reducing repeated puncture attempts.

Blunt Cannula: Aesthetic filler specialty custom needle—rounded tip displaces vessels and nerves rather than piercing them, dramatically reducing bruising and complication risks.

Wall Thickness Customization: The Flow Rate Secret

Custom needle wall thickness directly impacts fluid flow rates and injection pressure requirements at our needle factory.

Regular Wall (RW): Standard thickness suitable for most aqueous drug injection—balanced strength and flow characteristics in our custom needles.

Thin Wall (TW): Reduced wall thickness increases inner diameter in our custom needles, providing 20-30% improved flow rates without changing outer diameter. Ideal for emergency scenarios requiring rapid drug administration.

Ultra-Thin Wall (UTW): Specially designed custom needle for viscous liquids like oil-based vaccines and concentrated antibiotics. Significantly enlarged inner diameter reduces injection pressure, easing healthcare worker operation burden.

Extra-Thin Wall (XTW): Our needle factory produces these custom needles for biologics, monoclonal antibodies, and other high-value pharmaceuticals. Maximized inner diameter ensures smooth drug administration while minimizing costly drug waste.

Material Selection: Safety First in Custom Needle Manufacturing

304 Stainless Steel: Medical-grade standard material in our custom needles offering excellent corrosion resistance and mechanical strength—suitable for vast majority of medical applications with optimal cost-effectiveness.

316 Stainless Steel: Superior corrosion resistance in custom needles particularly appropriate for applications contacting corrosive medications or stored in humid environments.

Specialty Alloys: Non-magnetic alloy custom needles developed by our needle factory for patients requiring MRI examination—enabling magnetic resonance imaging without catheter removal, providing patient convenience.

Selecting Optimal Needle Size for Your Application

Needle size selection requires comprehensive consideration of multiple factors—no one-size-fits-all standard exists when sourcing from a needle factory.

Patient Factors: Primary Considerations for Needle Size

Age Variations: Newborns possess hair-thin vessels and minimal subcutaneous fat—requiring 26G-27G ultra-fine short needle sizes. Pediatric patients experience rapid growth-related body changes necessitating flexible needle size adjustments. Adults demonstrate wide physique variability requiring individualized needle size selection. Elderly patients exhibit reduced vascular elasticity and increased fragility—demanding appropriate needle size selection coupled with expert technique.

Body Habitus Impact on Needle Size: Lean patients with minimal subcutaneous fat need shorter needle sizes to avoid accidental intramuscular penetration. Standard builds accommodate routinely recommended needle sizes. Obese patients require longer needle sizes ensuring subcutaneous medications reach correct tissue layers—IV access also presents greater challenges potentially requiring extended-length needle sizes.

Vascular Condition: Some patients possess prominent, easily accessible veins. Conversely, long-term IV therapy patients, chemotherapy recipients, and dialysis patients often develop hardened, narrowed, low-elasticity vessels—requiring experienced healthcare professionals to select appropriate fine needle sizes with precise technique.

Drug Characteristics: Critical Considerations for Needle Size

Viscosity Determines Flow Requirements: Aqueous medications like saline and dextrose accommodate standard wall needle sizes. Oil-based drugs including certain vaccines and vitamins require thin-wall or ultra-thin-wall custom needle designs for increased inner diameter. Suspensions and emulsions potentially containing particles need sufficient inner diameter needle sizes preventing occlusion. High-concentration biologics with extreme viscosity necessitate extra-thin-wall custom needles for successful administration.

Volume Influences Needle Size Selection: Small-volume medications like insulin (0.5-1ml doses) work with fine needle sizes. Medium volumes such as vaccines (1-2ml) require balancing comfort and efficiency in needle size. Large-volume infusions may need larger needle sizes ensuring adequate flow rates. Emergency rapid fluid resuscitation absolutely demands large-bore needle sizes.

Irritant Properties Demand Caution: Highly irritating medications like certain chemotherapy agents and concentrated electrolytes require accurate IV delivery with appropriate needle size avoiding extravasation into surrounding tissue causing necrosis. Careful injection site selection and proper needle size pairing prove critical.

Injection Site Specificity and Needle Size

Intradermal Injection: Delivering approximately 0.1ml into skin’s superficial layers requires 26G-27G × 10mm short fine needle sizes inserted at nearly flat 15-degree angles, forming standard wheals. Common for allergy and tuberculin testing.

Subcutaneous Injection: Administering medication into subcutaneous tissue with moderate absorption rates. Requires 45-degree angle insertion to 0.5-1cm depth using 25G-27G × 16-19mm needle sizes. Appropriate for insulin, heparin, and certain vaccines.

Intramuscular Injection: Delivering drugs into muscle tissue for faster absorption. Requires perpendicular 90-degree insertion to 2-3cm depth using 20G-25G × 25-38mm needle sizes. Different anatomical sites have varying muscle thickness requiring corresponding needle size adjustments.

Intravenous Injection: Direct bloodstream entry providing fastest onset. Requires 15-30-degree angle insertion with blood flashback confirmation before advancement using 14G-26G needle sizes. Emergency, infusion, and IV medication scenarios each demand different needle size specifications.

Injection Frequency: The Balance in Needle Size Selection

Single-Dose Administration: Pre-surgical medications or emergency drugs prioritize injection efficiency—moderately larger needle sizes ensure adequate delivery speed with acceptable transient discomfort.

Occasional Injections: Annual vaccinations or monthly long-acting formulations balance efficiency and comfort—standard recommended needle sizes from reliable needle factory sources suffice.

Frequent Administration: Diabetic patients requiring 3-4 daily insulin injections, hemophiliacs needing clotting factor replacement, dialysis patients with repeated punctures must prioritize long-term comfort and vascular preservation—select finest possible needle sizes combined with injection site rotation strategies.

Continuous Therapy: Patients requiring prolonged infusion like chemotherapy recipients or ICU patients should consider IV catheters (peripheral cannulas)—single insertion lasting several days dramatically reduces repeated puncture trauma.

Kohope Needle Factory: Your Trusted Global Custom Needle Partner

In the competitive medical device marketplace, Kohope needle factory earns worldwide client trust through professionalism, quality, and custom needle service excellence.

Complete Needle Size Coverage

Our needle factory product line encompasses all gauges from 7G to 34G with lengths spanning 6mm to 150mm—whether you need neonatal micro-needle sizes or reinforced livestock needle sizes, we deliver. Standard needle sizes maintain robust inventory; special custom needle specifications enable rapid production.

Multi-Application Custom Needle Solutions: One-Stop Service

Human Healthcare: From community clinics to tertiary hospitals, from routine infusion to complex surgery, our custom needles in various needle sizes serve all healthcare institution levels.

Veterinary Field: Pet hospitals, zoos, farms, and equestrian facilities find suitable custom needle products from our needle factory. We understand diverse species’ unique needle size requirements.

Aesthetic Industry: Premium medical aesthetic centers and cosmetic clinics trust our precision custom needles. Comprehensive coverage of blunt cannulas, sharp needles, and microneedles in optimal needle sizes for professional beauty applications.

Laboratory Research: Biological laboratories, pharmaceutical R&D, and disease control centers utilize our precision custom needles for diverse experiments and testing across multiple needle size specifications.

International Certifications: Quality Assurance from Our Needle Factory

Kohope needle factory maintains ISO 13485 Medical Device Quality Management System certification, EU CE marking, and US FDA registration. Our custom needles export to over 60 countries across Europe, Americas, Southeast Asia, and Middle East. Every batch of custom needles undergoes rigorous quality testing ensuring international standard compliance for all needle sizes.

Flexible Custom Needle Manufacturing: MOQ-Friendly

Unlike many large manufacturers requiring tens of thousands minimum orders, Kohope needle factory supports small-batch custom needle production with friendly MOQ (minimum order quantity)—particularly suitable for specialized medical institutions, research units, and startup aesthetic brands needing specific needle sizes. We provide free samples for testing and evaluation of our custom needles.

Rapid Delivery from Our Needle Factory: Efficient Service

Standard Needle Sizes: Well-stocked conventional needle size specifications ship within 3-7 business days meeting urgent requirements.

Custom Needle Orders: Depending on complexity, custom needle production cycles range 15-30 days—our needle factory provides precise delivery schedules immediately upon order receipt for any needle size.

Emergency Orders: Understanding healthcare industry urgency, our needle factory arranges expedited custom needle production and shipping for emergency orders ensuring no usage delays.

Professional Technical Support for Needle Size Selection

Kohope needle factory’s experienced technical team provides:

- Needle Size Selection Consultation: Recommending optimal needle size solutions for specific application scenarios

- Custom Needle Design: Comprehensive custom needle specifications from bevel angles to wall thickness, coating selection to packaging design

- Usage Training Guidance: Providing custom needle product manuals and training materials for proper needle size applications

- After-Sales Technical Support: Rapid response to any custom needle usage questions and needle size selection queries

Contact Kohope Needle Factory to Begin Your Custom Needle Journey

Whether you’re a hospital procurement specialist seeking reliable needle factory suppliers, an aesthetic clinic requiring precision beauty needles in specific needle sizes, or a veterinary practice wanting to optimize animal care experiences with appropriate custom needles, Kohope provides the most professional custom needle solutions.

Precise needle size selection forms the foundation of medical safety, patient comfort assurance, and treatment efficacy optimization. As a professional needle factory with decades of experience, we don’t simply manufacture needles—we dedicate ourselves to understanding each application scenario’s unique needle size requirements, contributing our custom needle expertise to global healthcare excellence.

Contact Kohope Needle Factory today—let us customize the perfect medical needles in the ideal needle size for your needs!