Description

Precision Medical Needle Size for Injection Systems

At Kohope needle factory, we specialize exclusively in medical-grade injection needles for syringe manufacturers and medical device companies. Our production range covers the complete spectrum of clinical needle size requirements—from ultra-fine 30G and 32G needles for insulin delivery and vaccinations, to larger 18G and 20G needles for blood collection and fluid administration.

Each needle size is manufactured to meet USP and ISO standards, with dimensional tolerances maintained at ±0.025mm for outer diameter and ±0.013mm for inner diameter. We use surgical-grade stainless steel 304 and 316L exclusively, ensuring biocompatibility and corrosion resistance critical for medical applications.

Solving Critical Quality Challenges for Medical Device Manufacturers

We understand the pain points that keep medical device companies awake at night. Inconsistent needle size tolerances can lead to production line rejections, regulatory compliance issues, and costly product recalls. When your current supplier delivers needles with diameter variations exceeding specifications, your entire production schedule suffers.

Poor surface finish quality creates another critical problem. Burrs, scratches, or rough inner walls cause patient discomfort, increase injection force requirements, and risk tissue damage. These defects aren’t just quality issues—they’re patient safety concerns that damage your brand reputation.

Unreliable supply chains disrupt your manufacturing operations. Late deliveries, inconsistent lead times, and suppliers who can’t scale with your growth force you to maintain excessive safety stock or risk production shutdowns. You need a needle factory partner who understands that medical device production cannot tolerate supply uncertainty.

Our needle factory addresses these challenges systematically. We maintain strict process controls with real-time SPC monitoring, ensuring every needle size meets specifications consistently. Our multi-stage inspection process includes automated optical inspection, dimensional verification, and flow rate testing before any product ships.

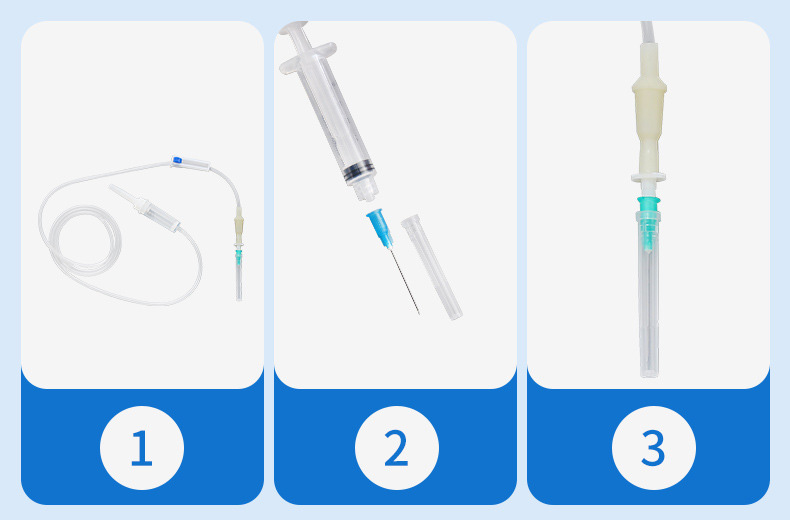

Comprehensive Medical Needle Size Range

Our needle factory produces injection needles across the complete medical gauge spectrum. For diabetes care and insulin delivery, we manufacture 28G, 29G, 30G, and 32G needle size options with ultra-thin wall technology that maximizes flow rates while minimizing patient discomfort. Pediatric and geriatric applications benefit from our precision manufacturing that ensures consistent, gentle injections.

For vaccination and immunization programs, we supply 23G, 25G, and 27G needle size specifications optimized for intramuscular and subcutaneous administration. Our needles feature precision-ground tri-bevel tips that reduce penetration force and tissue trauma, critical factors for mass vaccination campaigns and routine immunizations.

Blood collection and phlebotomy applications require our 18G, 20G, 21G, and 22G needle size products. These needles are manufactured with optimized inner diameter specifications that prevent hemolysis while enabling efficient blood flow. We offer both regular wall and thin wall configurations depending on your specific collection system requirements.

For intravenous therapy and fluid administration, we produce 18G through 24G needle size options suitable for various IV catheter systems and infusion devices. Our manufacturing process ensures smooth inner surfaces that facilitate catheter insertion and reduce the risk of catheter damage during deployment.

Custom Needle Solutions for Specialized Medical Devices

Standard needle size specifications don’t always meet the requirements of innovative medical devices. Our custom needle development service supports medical device companies developing next-generation injection systems, auto-injectors, pre-filled syringes, and specialized drug delivery platforms.

When your device requires custom needle lengths outside standard ranges, modified tip geometries for specific tissue types, or specialized wall thickness ratios for viscous medications, our engineering team collaborates with you from concept through production. We’ve developed custom needles for biologics delivery systems requiring enhanced flow characteristics, multi-chamber syringes needing precise internal dimensions, and wearable injection devices with unique space constraints.

Our custom needle capabilities include specialized bevel angles optimized for different injection depths, laser-marked graduation lines for precise dosing applications, proprietary coating applications for reduced friction and improved medication compatibility, and non-standard hub configurations for unique syringe systems. We maintain strict confidentiality and can sign NDAs to protect your proprietary device designs.

Superior Surface Quality and Patient Safety

Patient comfort and safety depend on exceptional needle surface quality. Our needle factory employs advanced electropolishing processes that create mirror-smooth inner and outer surfaces, dramatically reducing injection force and tissue trauma. Unlike mechanically polished needles that can leave microscopic imperfections, our electropolished needles provide consistently smooth surfaces that minimize patient discomfort.

We understand that rough inner walls create resistance during injection, increasing the force required and potentially causing medication shearing for sensitive biologics. Our precision bore-honing process ensures Ra values below 0.4μm on inner surfaces, facilitating smooth medication flow and protecting delicate pharmaceutical compounds.

Burrs and sharp edges at the needle hub connection point create serious risks—they can shed particles into medications, cause micro-leaks, or create loose-fit connections with syringe barrels. Our multi-stage deburring and inspection process eliminates these defects, ensuring every needle provides secure, leak-free connections and particle-free performance.

Free Sample Testing Program – Experience Our Quality

We understand that changing needle suppliers represents a significant decision with real risks. That’s why we offer free sample testing to qualified medical device manufacturers. Experience our quality firsthand before making any commitment to production orders.

Our free sample program includes representative samples of your required needle size specifications, complete dimensional inspection reports and certificates of analysis, sterilization compatibility documentation if needed, and technical consultation to discuss your specific application requirements. Many of our current clients started with free samples and discovered quality improvements they hadn’t expected—better dimensional consistency, smoother surfaces, and more reliable supply chain performance.

Request your free samples today. Our team will contact you within 24 hours to understand your requirements and arrange sample shipment. We typically ship sample packages within 5-7 business days, complete with all technical documentation you need for evaluation.

ISO 13485 Quality Systems and Medical Compliance

Every needle size we produce meets stringent medical device quality standards. Our needle factory operates under ISO 13485:2016 certification, specifically designed for medical device manufacturing. We maintain comprehensive quality management systems with full traceability from raw material receipt through final product shipment.

Our quality documentation includes material certificates tracing steel to mill test reports, dimensional inspection reports with actual measurements, biocompatibility test coordination and documentation, endotoxin testing for sterile packaging applications, and certificates of compliance for FDA, CE, and other regulatory requirements. For medical custom needles, we provide complete design history files and validation documentation supporting your regulatory submissions.

We perform 100% visual inspection using automated optical systems that detect surface defects invisible to manual inspection. Statistical process control monitors critical dimensions in real-time, with immediate corrective action protocols when any parameter approaches specification limits. Our quality assurance team has extensive experience supporting medical device manufacturers through regulatory audits and customer quality assessments.

Medical-Grade Materials and Sterilization Compatibility

Our needle factory uses exclusively surgical-grade stainless steel meeting ASTM and ISO material specifications for medical devices. Type 304 stainless steel provides excellent corrosion resistance and mechanical properties for most applications, while Type 316L offers enhanced chemical resistance for specialized medications and aggressive sterilization processes.

All materials include complete mill test reports and chemical composition analysis. We verify material properties through independent testing, ensuring compliance with USP Class VI biocompatibility requirements and ISO 10993 biological evaluation standards.

Our needles are fully compatible with all standard sterilization methods including ethylene oxide (EtO), gamma irradiation, electron beam sterilization, and autoclave steam sterilization. We provide sterilization validation support data and can coordinate sterilization compatibility testing for your specific packaging and sterilization parameters. Surface treatments and electropolishing processes are validated to maintain integrity through sterilization cycles without degradation.

Reliable Supply Chain for Medical Device Production

Production delays due to needle supply issues create cascading problems for medical device manufacturers. Our needle factory maintains safety stock of common needle size specifications, enabling rapid response to urgent orders and protecting your production schedule from supply disruptions.

We understand that medical device production operates on tight schedules with regulatory deadlines. Our production planning system prioritizes medical orders and maintains buffer capacity for demand surges. Standard lead times range from 2-4 weeks for stock needle size specifications, with expedited production available when you face urgent requirements.

For custom needle development, we provide realistic timelines with milestone tracking. Prototype samples typically ship within 10-14 days, with production validation completed within 6-8 weeks depending on complexity. Once validated, we maintain your custom specifications in our system for seamless repeat ordering.

Our inventory management programs help medical device companies reduce working capital while ensuring supply security. We offer vendor-managed inventory solutions, scheduled delivery programs aligned with your production cycles, and safety stock agreements that protect against supply chain disruptions. You focus on developing life-saving medical devices; we ensure needle supply never becomes your bottleneck.

Technical Support and Regulatory Assistance

Choosing Kohope means gaining a needle factory partner committed to your medical device success. Our technical support team includes engineers with extensive medical device experience who understand the unique challenges of syringe and injection system manufacturing.

We assist with needle size selection based on medication viscosity, injection volume, and patient population. Our engineers can recommend optimal wall thickness, bevel geometry, and length specifications for your specific application. When you’re developing new devices, we provide early design input that prevents costly redesigns and accelerates time to market.

Our regulatory support team helps navigate compliance requirements across different markets. We provide documentation packages supporting FDA 510(k) submissions, CE marking technical files, and other regulatory pathways. Our quality team has experience responding to regulatory questions and supporting customer audits, helping you maintain compliance throughout your product lifecycle.

We maintain open communication channels—technical questions receive responses within 24 hours, and our team proactively alerts you to any potential supply chain issues before they impact your production. This partnership approach has helped our clients avoid production disruptions, improve product quality, and reduce total cost of ownership.

Contact Kohope for Free Sample Testing

Stop struggling with inconsistent needle quality, unreliable suppliers, and supply chain disruptions. Request your free samples today and discover why leading medical device manufacturers trust Kohope as their needle factory partner.

Our team is ready to discuss your needle size requirements, address your quality concerns, and demonstrate how our manufacturing excellence can improve your product performance and reduce your supply chain risks. Whether you need standard medical needle size specifications or custom needle solutions for innovative devices, we have the expertise and capacity to support your growth.

Contact us now for free sample testing, technical specifications, quotations, or to schedule a virtual factory tour. Experience the Kohope difference—where precision manufacturing meets reliable partnership