Description

Comprehensive Medical Plastic Syringe Range for Diverse Clinical Applications

Understanding Your Procurement Priorities

When sourcing medical supplies, healthcare procurement managers and wholesale buyers face critical decisions balancing quality, compliance, cost-efficiency, and supplier reliability. Our plastic syringe manufacturing capabilities address these core concerns through certified production standards, flexible order quantities, and application-specific designs.

For Hospital Procurement Teams: You require consistent quality across large volume orders with strict regulatory compliance. Our ISO 13485 and CE certified irrigation syringes eliminate quality variance risks while maintaining competitive bulk pricing structures.

For Veterinary Supply Distributors: Animal healthcare demands durable, versatile tools. Our medical-grade oral syringe options serve both small animal care and large livestock applications with the same reliability standards as human medical devices.

For Private Label Partners: Brand differentiation matters in competitive markets. Our OEM/ODM services provide custom packaging, color-coding systems, and specification modifications to align with your unique market positioning.

Multi-Application Design Philosophy

Ear Irrigation Applications

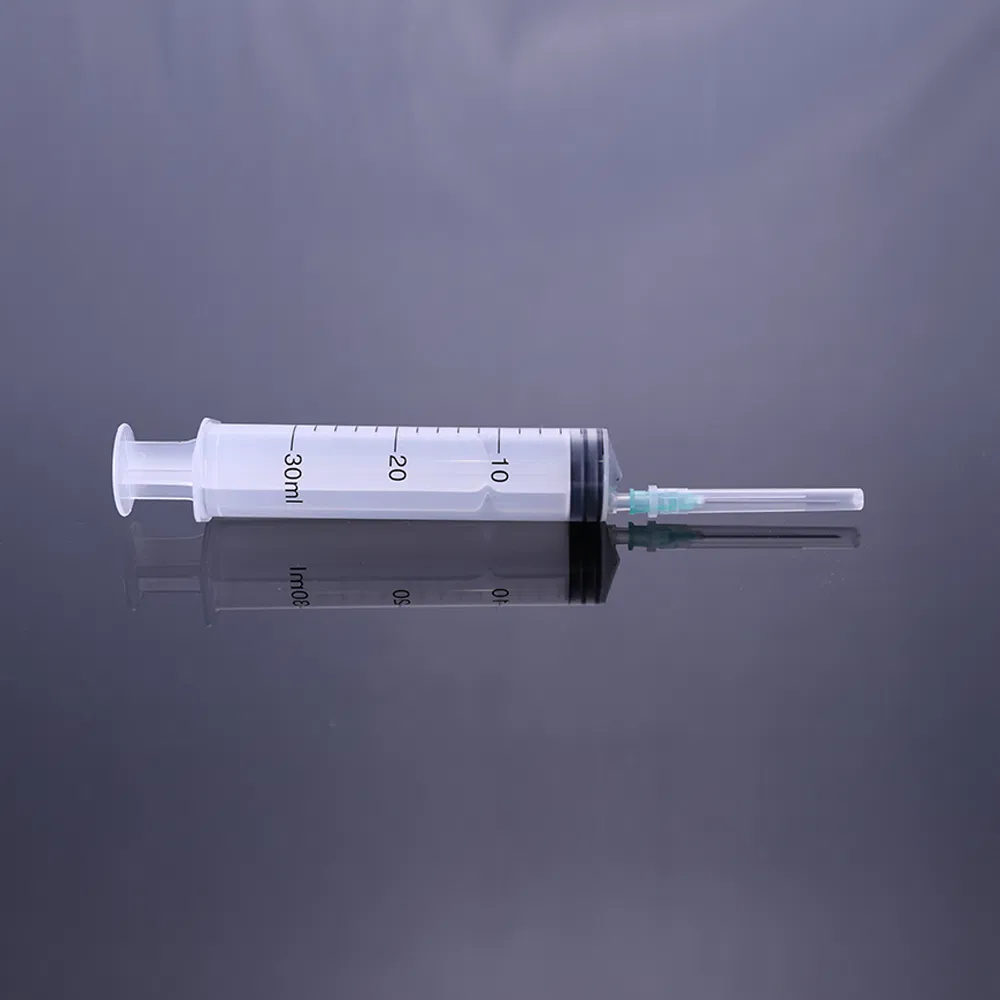

Medical professionals performing ear cleaning procedures need irrigation syringes that deliver controlled water flow without excessive pressure. Our 20ml-60ml capacity options feature smooth plunger action for precise fluid delivery, reducing patient discomfort during cerumen removal procedures. The transparent PP barrel allows visual monitoring of fluid volume, critical for safety protocols in ENT departments.

Procurement Consideration: Bulk buyers appreciate our standardized cannula sizing compatible with existing irrigation tips, eliminating additional accessory costs.

Ophthalmic Care Solutions

Eye care professionals require sterile, gentle fluid delivery systems. Our smaller capacity plastic syringe models (1ml-5ml) provide the precision needed for eye wash procedures and medication administration. The Luer Lock mechanism ensures secure attachment to ophthalmic cannulas, preventing disconnection during delicate procedures.

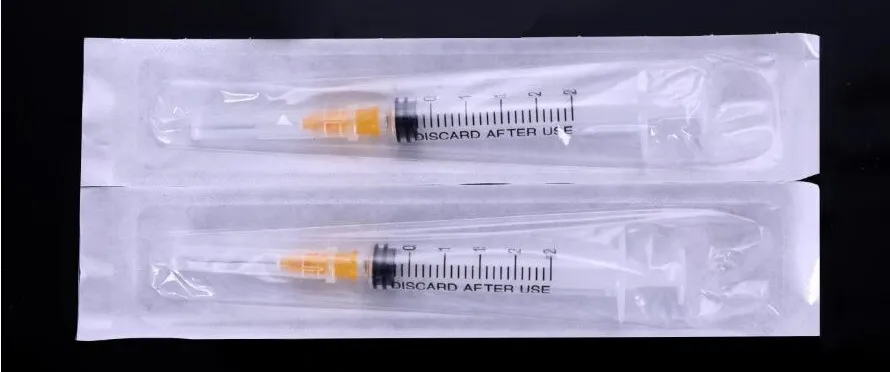

Wholesale Value Proposition: Pre-sterilized individual packaging reduces hospital sterilization department workload while maintaining aseptic standards.

Muscle Injection Precision

Intramuscular medication delivery demands reliable needle attachment and smooth medication flow. Our plastic syringe series with hypodermic needles features medical silicone lubrication (ISO 7864) ensuring consistent plunger movement even with viscous medications. Stainless steel AISI 304 needles provide sharpness retention and tissue trauma minimization.

Cost Analysis for Buyers: The 5-year shelf life significantly reduces inventory turnover costs compared to shorter-dated alternatives, improving your working capital efficiency.

Oral Medication Administration

Pediatric and geriatric care often requires needle-free medication delivery. Our oral syringe configurations without needles offer safe, accurate dosing for liquid medications. The clear scale markings (indelible per ISO standards) prevent dosing errors, a critical safety feature that reduces liability concerns for healthcare facilities.

Technical Specifications Meeting International Standards

Material Quality Assurance

Barrel Construction: Medical-grade high-transparency polypropylene (PP) provides chemical resistance and clarity. Procurement managers appreciate PP’s compatibility with standard sterilization protocols and its non-reactive properties with most pharmaceutical preparations.

Plunger System: Environment-friendly natural rubber plungers create optimal seals without requiring excessive force. This reduces healthcare worker fatigue during high-volume vaccination campaigns or fluid therapy sessions.

Needle Components: AISI 304 stainless steel construction meets corrosion resistance requirements for diverse storage environments. Color-coded per ISO 6009 standards facilitates quick gauge identification, reducing medication errors in fast-paced clinical settings.

Capacity Range Strategy

Our irrigation syringes span 1ml to 60ml capacities, addressing procurement strategies focused on inventory consolidation:

- 1ml-3ml: Precise medication dosing, pediatric applications

- 5ml-10ml: Standard injection volumes, vaccine administration

- 20ml-30ml: Wound irrigation, ear cleaning procedures

- 50ml-60ml: Large volume irrigation, veterinary applications

Wholesale Advantage: Single-supplier sourcing across all capacity ranges simplifies vendor management and potentially qualifies for volume-based pricing tiers.

Regulatory Compliance & Quality Certifications

CE Marking & ISO 13485 Certification

European market access requires CE conformity for medical devices. Our plastic syringe products maintain current CE certification through regular third-party audits, ensuring uninterrupted supply for EU-based buyers. The ISO 13485 quality management system demonstrates systematic process controls that wholesale buyers require for their own compliance documentation.

Procurement Risk Mitigation: Certified suppliers reduce your regulatory audit exposure and accelerate product registration in controlled markets.

EO Gas Sterilization Standards

Ethylene oxide sterilization ensures our oral syringe and injection models achieve non-toxic, non-pyrogenic status critical for patient safety. Individual sterile packaging maintains aseptic integrity until point-of-use, meeting hospital infection control protocols.

Packaging Solutions for Distribution Efficiency

Retail-Ready Packaging Options

Choose between polythene (PE) or paper-plastic packaging based on your market requirements:

PE Packaging: Cost-effective for high-volume institutional buyers, provides moisture barrier protection for diverse climate conditions.

Paper-Plastic Blister Packs: Premium presentation for pharmacy retail channels, offers visual product inspection while maintaining sterile barriers.

Distribution Consideration: Both packaging formats optimize shipping cube utilization, reducing your logistics costs per unit.

OEM/ODM Customization Services

Private Label Partnership Opportunities

Brand differentiation in competitive medical supply markets requires unique product positioning. Our OEM/ODM capabilities include:

Custom Scale Printing: Incorporate your brand logo directly on irrigation syringes barrels using medical-grade inks that withstand sterilization processes.

Modified Specifications: Adjust plunger length, barrel transparency levels, or needle gauge combinations to create exclusive product lines for your distribution channels.

Packaging Design: Develop custom carton graphics, multi-language instructions, and batch tracking systems aligned with your quality management requirements.

Strategic Advantage for Buyers: Private label plastic syringe products command higher margins while building brand loyalty among end-user healthcare facilities.

Minimum Order Quantities & Lead Times

We structure MOQs to balance production efficiency with accessible entry points for new wholesale partners:

- Standard Products: Lower MOQs suitable for market testing or smaller distributor operations

- Custom Specifications: Volume commitments reflect tooling investments, with transparent pricing structures

- Rush Orders: Expedited production available for emergency procurement situations or seasonal demand spikes

Quality Assurance & Shelf Life Management

5-Year Shelf Life Benefits

Extended shelf life addresses multiple procurement concerns:

Inventory Flexibility: Larger safety stock levels without obsolescence risk, crucial for rural healthcare facilities with unpredictable demand patterns.

Disaster Preparedness: Emergency medical supply stockpiles maintain readiness without frequent rotation requirements.

Cost Averaging: Bulk purchasing during favorable pricing periods without short-term usage pressure.

Batch Traceability Systems

Every oral syringe and irrigation syringe production batch includes complete documentation covering raw material certifications, production parameters, and sterilization validation. This traceability supports your recall preparedness protocols and satisfies regulatory inspection requirements.

Competitive Advantages for Wholesale Buyers

Price-Performance Optimization

Medical-grade quality doesn’t require premium pricing. Our plastic syringe manufacturing scale achieves cost efficiencies passed to wholesale partners through:

- Volume Discount Tiers: Structured pricing rewards larger commitments while remaining accessible

- Consistent Specifications: Reduced defect rates minimize your quality control inspection costs

- Standardized Components: Interchangeable parts across size ranges simplify your inventory management systems

Supplier Reliability Indicators

Procurement decision-makers evaluate supplier partnerships on multiple dimensions beyond unit pricing:

Production Capacity: Our facilities maintain buffer capacity for demand surges, protecting your supply continuity during market disruptions.

Technical Support: Engineering team availability for specification consultations, regulatory documentation support, and application guidance.

Payment Terms: Flexible arrangements for established wholesale partners, supporting your cash flow management.

Application-Specific Purchasing Scenarios

Hospital Central Supply Chain Managers

Scenario: Annual contract renewal for general-purpose syringes across 12 department inventory locations.

Key Concerns: Standardization across departments, regulatory compliance documentation, just-in-time delivery coordination, budget predictability.

Our Solution: Consolidated plastic syringe portfolio reduces SKU complexity. Scheduled delivery programs align with your consumption patterns. Fixed annual pricing protects against market volatility.

Veterinary Supply Wholesalers

Scenario: Expanding product line to serve both companion animal clinics and agricultural livestock operations.

Key Concerns: Durability for large animal use, cost-effectiveness for high-volume applications, differentiation from human medical products.

Our Solution: Identical quality standards ensure performance reliability. Custom packaging clearly identifies veterinary designation. Irrigation syringes in larger capacities serve agricultural applications.

Pharmacy Chain Procurement Directors

Scenario: Private label oral medication syringe program for pediatric OTC products.

Key Concerns: Child-safe design features, retail packaging aesthetics, brand exclusivity, point-of-sale presentation.

Our Solution: OEM oral syringe program with custom color options. Retail-optimized blister packaging. Exclusive distribution agreements available for qualified partners.

International Medical Equipment Distributors

Scenario: Sourcing reliable supplier for multi-country distribution covering diverse regulatory environments.

Key Concerns: CE marking validity, documentation packages for various jurisdictions, container load optimization, consistent quality across shipments.

Our Solution: Comprehensive regulatory support documentation. Efficient packaging for sea freight economics. Established quality systems ensure batch-to-batch consistency.

Ordering Process & Customer Support

Streamlined Procurement Workflow

- Specification Consultation: Technical team reviews your application requirements

- Sample Evaluation: Representative units for quality assessment and compatibility testing

- Quotation Development: Transparent pricing with volume tier structure

- Order Confirmation: Clear lead times and delivery schedule coordination

- Quality Documentation: Certificates of analysis, sterilization validation, regulatory certificates

- Logistics Coordination: Shipping arrangement optimization for your receiving capabilities

Post-Purchase Support

Product Training: Usage guidelines and best practice recommendations for your sales teams or end-users

Regulatory Assistance: Documentation support for your product registration or compliance needs

Reorder Management: Simplified repeat ordering with maintained pricing and specifications

Environmental & Safety Considerations

Our manufacturing processes prioritize environmental responsibility through recyclable PP materials and natural rubber components. Medical waste disposal guidelines are included with bulk shipments to support your sustainability initiatives.

Worker safety in healthcare settings benefits from our ergonomic design features—smooth plunger operation reduces repetitive strain injuries during high-volume administration periods.

Ready to Optimize Your Medical Supply Procurement?

Whether you need standard plastic syringe inventory, customized irrigation syringes for specialized applications, or private label oral syringe programs, our team provides tailored solutions matching your business model.

Contact our wholesale division to discuss volume pricing, specification customization, or partnership opportunities. Experience the procurement advantages of working with a certified medical device manufacturer committed to your supply chain success.