Description

Professional Pre-Filled Syringe Manufacturing by Kohope

At Kohope, we specialize in producing high-quality pre-filled glass syringes that meet the demanding standards of the pharmaceutical and medical industries. Our manufacturing facility operates under 10,000+100 class cleaning workshop conditions, ensuring every product meets international quality benchmarks.

Superior Glass Construction

Our pre-filled syringes are crafted from premium heat-resistant borosilicate glass (USP Type I neutral glass). This specialized material offers exceptional durability and safety:

- Thermal Stability: Engineered to withstand sudden temperature changes without compromising integrity

- Impact Resistance: Advanced material composition resists breakage from shock and handling stress

- Strain-Free Quality: Each syringe undergoes annealing and rigorous testing to eliminate internal strain

- Reusable Durability: Capable of withstanding repeated washing with hot water for multi-use applications

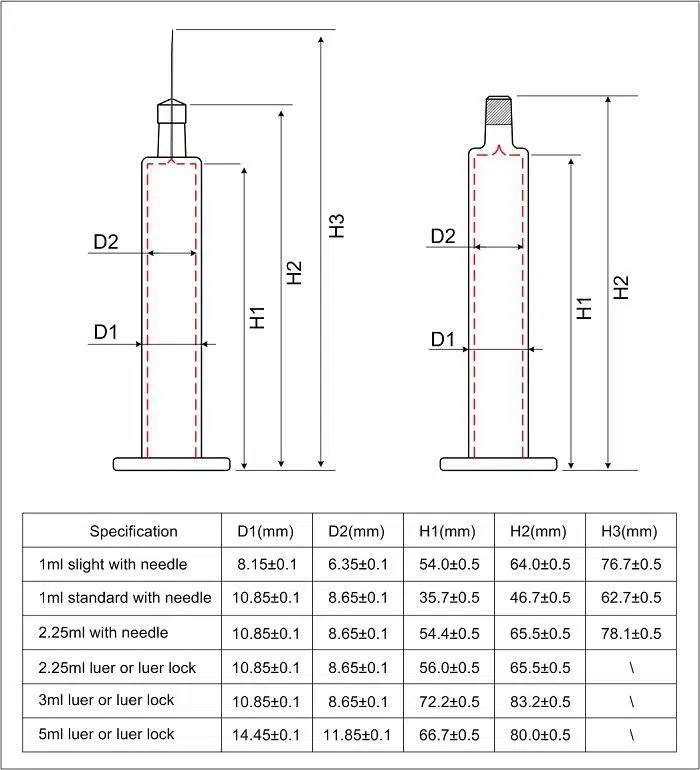

Technical Specifications

| Specification | Details |

|---|---|

| Product Name | Pre-filled Glass Syringes |

| Available Volumes | 1ml, 2ml, 3ml, 5ml, 10ml, 20ml |

| Usage | Injection, Puncture, Surgical Treatment, Cosmetic Applications |

| Luer Options | Luer slip or Luer lock |

| Barrel Material | Borosilicate Glass, USP Type I Neutral Glass |

| Glass Color | Clear |

| Lubricant | Medical-grade Silicone Oil (ISO764 and USP CLASS VI) |

| Sterilization | EO Gas Sterilization – Non-toxic, Non-pyrogenic |

| Production Capacity | 10 Million pieces per month |

| Shelf Life | 5 years |

| Workshop Standard | 10,000+100 Class Cleaning Workshop |

| Quality Certifications | CE, ISO, SFDA, GMP Standard |

| OEM Service | Available |

| Logo & Text Printing | Yes, Customizable |

| MOQ | 5,000 pieces |

| Delivery Time | 15-30 days for one 20ft container |

| Inner Packaging | Tyvek bag and nest box for glass barrel, PE bag for plunger stopper and rod |

| Outer Packaging | 5-layer strong corrugated carton |

| Additional Protection | Pallet or wooden box available |

Key Advantages

Safety & Sterility: Our pre-filled syringes arrive ready for use with drug solutions prepared in sterile conditions, maximizing safety and eliminating contamination risks.

Clinical Excellence: Ideal for injections, puncture procedures, surgical treatments, and cosmetic applications. The pre-filled design prevents cross-infection and ensures consistent dosing.

Convenience: Eliminates preparation time and reduces medication waste, improving overall efficiency in medical settings.

Customization: We offer OEM services, custom logo and text printing, and flexible packaging solutions to meet your specific requirements.

Quality Assurance

Every Kohope pre-filled syringe undergoes stringent quality control in our GMP-certified facility. We maintain partnerships with leading material suppliers to ensure access to cutting-edge technologies and consistently superior products. Our commitment to social responsibility and sustainable manufacturing practices guarantees reliable, long-lasting medical solutions.

Why Choose Kohope?

- Advanced Manufacturing: State-of-the-art cleanroom facilities ensuring pharmaceutical-grade quality

- High Capacity: 10 million pieces monthly production capacity for reliable supply

- Global Standards: Full compliance with international medical device regulations

- Custom Solutions: Flexible OEM services to meet your unique specifications

- Proven Reliability: 5-year shelf life with consistent quality performance