Description

1. Introduction

1. Introduction

Our Factory Custom ISO – Approval Disposable Medical Spinal Needle is a specialized medical device crafted with precision and designed to adhere to the strictest international standards. As a factory – customized product, it offers a unique solution for medical professionals performing spinal procedures, ensuring both reliability and adaptability to diverse patient needs.

2. Customization Options

- Length Customization

- We understand that different patients and spinal procedures may require needles of varying lengths. Our factory can produce spinal needles with lengths ranging from 80mm to 150mm. Shorter needles, around 80 – 100mm, may be suitable for pediatric patients or those with a thinner spinal column. Longer needles, such as 120 – 150mm, are designed for adult patients with a more robust spinal structure or for procedures that require deeper penetration.

- Gauge Customization

- The gauge of the spinal needle is a critical factor. Our customization options include gauges from 22G to 27G. A larger gauge like 22G may be used when a larger – diameter needle is necessary for procedures that require the passage of certain substances, such as anesthetics or contrast agents. Smaller gauges, such as 27G, are preferred when minimizing tissue trauma is a priority, as they cause less damage to the spinal tissues during insertion.

- Tip Design Customization

- The tip of the spinal needle can be customized to meet specific procedural requirements. We offer options like the Quincke tip, which has a sharp, beveled edge and is commonly used for general spinal anesthesia. Another option is the Whitacre tip, a non – cutting, pencil – point tip that is designed to separate the spinal meninges rather than cut through them, potentially reducing the risk of post – dural puncture headache.

3. ISO Approval Significance

- Quality Assurance

- Our disposable medical spinal needles hold ISO approval, which is a testament to their high – quality manufacturing. ISO standards cover all aspects of production, from raw material sourcing to the final packaging. This ensures that every needle meets the stringent requirements for safety, performance, and reliability. For medical professionals, this means they can trust that the needles they use are of the highest quality and will perform consistently during spinal procedures.

- International Acceptance

- ISO approval also allows our spinal needles to be accepted and used in medical facilities worldwide. It eliminates the need for additional, often – complex, local certifications in different countries, facilitating the global distribution of our products. This is particularly beneficial for large – scale medical suppliers and international healthcare organizations.

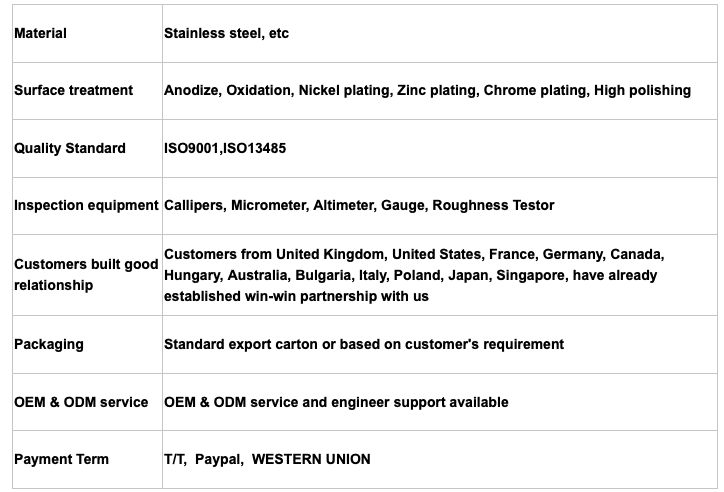

4. Product Specifications

5. Applications

- Lumbar Puncture

- Our spinal needles are commonly used in lumbar puncture procedures. This involves inserting the needle into the subarachnoid space in the lower back to obtain a sample of cerebrospinal fluid for diagnostic purposes, such as detecting infections, measuring pressure, or diagnosing neurological disorders. The customizable features of our needles, such as length and gauge, enable medical professionals to perform the procedure with precision and minimize patient discomfort.

- Spinal Anesthesia

- For spinal anesthesia, where an anesthetic agent is injected into the spinal canal to numb the lower part of the body during surgery, our needles play a crucial role. The ability to customize the tip design, along with the accurate dosing provided by the precisely manufactured needles, ensures effective anesthesia while reducing the risk of complications.

6. Factory – Direct Benefits

- Cost – Efficiency

- As a factory – direct product, we can offer our customized spinal needles at competitive prices. By eliminating middle – men, we pass on significant cost savings to our customers, whether they are small clinics or large hospitals. This cost – efficiency does not come at the expense of quality, as our ISO – approved manufacturing process ensures high – standard products.

- Direct Communication and Quick Turnaround

- Working directly with our factory allows for direct communication between customers and our production team. This enables us to understand specific requirements clearly and make adjustments promptly. We can also offer a relatively quick turnaround time for custom orders, ensuring that medical facilities can obtain the needles they need in a timely manner.

In conclusion, our Factory Custom ISO – Approval Disposable Medical Spinal Needle is a top – tier product that combines customization, quality, and cost – efficiency. It is an essential tool for medical professionals performing spinal procedures, providing the reliability and adaptability required in modern healthcare.