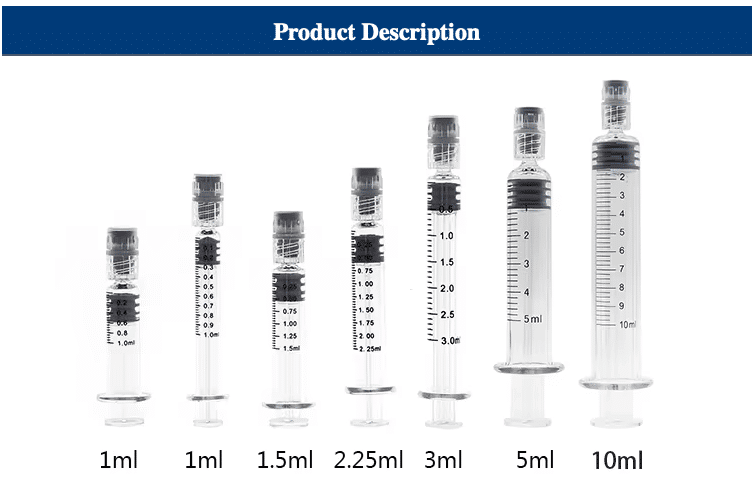

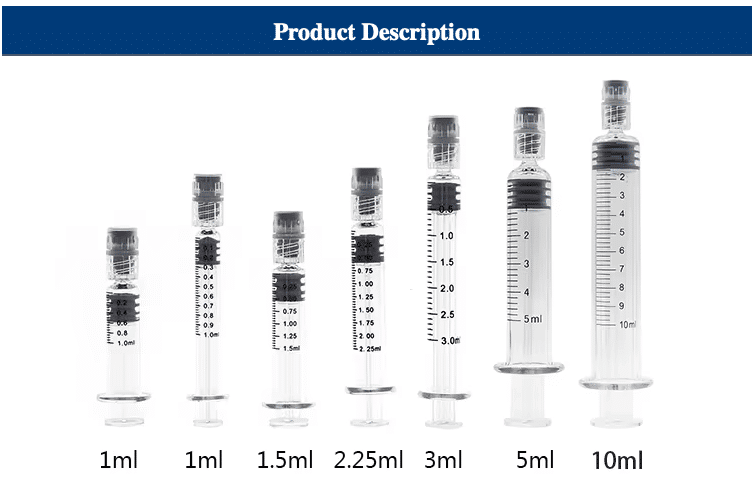

Our 0.5ml/1ml/3ml/5ml/10ml Prefilled Glass Syringes for Injection or Cosmetic use are a versatile and high – quality product line designed to meet the diverse needs of medical and cosmetic industries. These syringes combine the elegance of glass with the functionality of metal or plastic plungers, ensuring precision, reliability, and safety.

- 0.5ml Syringe

- Ideal for applications that require extremely precise and small – volume dosing. In the medical field, it can be used for injecting minute amounts of medications, such as certain hormones or high – potency drugs. In the cosmetic industry, it may be used for dermal fillers in small areas like the lips or around the eyes. The small capacity allows for meticulous control over the amount of substance being injected.

- The glass barrel provides excellent clarity, enabling easy visualization of the liquid level. This is crucial for accurate dosing, especially when dealing with small volumes.

- 1ml Syringe

- A popular choice for a wide range of injection and cosmetic procedures. In medical settings, it is commonly used for vaccinations, local anesthetics, and some subcutaneous injections. For cosmetic applications, it can be used for administering botulinum toxin or small – volume dermal fillers. The 1ml capacity offers a balance between precision and the ability to deliver a sufficient amount of product.

- The graduations on the glass barrel are clearly marked, usually with an accuracy of ±0.01ml, ensuring precise measurement.

- 3ml Syringe

- Versatile for both medical and cosmetic uses. In medicine, it can be used for intramuscular injections, drawing samples, or irrigating small wounds. In the cosmetic industry, it may be used for larger – volume dermal fillers in areas like the cheeks or for injecting certain cosmetic solutions. The 3ml capacity provides more flexibility in dosing compared to the 0.5ml and 1ml syringes.

- The glass barrel is robust yet transparent, allowing for clear visibility of the contents and accurate reading of the volume markings.

- 5ml Syringe

- In the medical field, this capacity is often used for wound irrigation, larger – volume intramuscular or subcutaneous injections, and for administering some medications that require a higher volume. In the cosmetic industry, it can be used for injecting larger amounts of fat – dissolving solutions or for more extensive dermal filler applications. The 5ml syringe is designed to handle a significant volume while maintaining ease of use.

- The graduations on the barrel are bold and easy to read, with an accuracy of ±0.02ml, facilitating accurate dosing.

- 10ml Syringe

- Primarily used for applications that require a relatively large volume of liquid. In medicine, it can be used for intravenous injections of certain medications, aspirating fluids from body cavities, or for large – scale wound irrigation. In the cosmetic field, it may be used for injecting large – volume solutions in body – contouring procedures. The 10ml capacity makes it suitable for more substantial injection needs.

- The glass barrel is thick – walled to provide strength and durability when handling larger volumes. The graduations are designed for easy reading, with an accuracy appropriate for the larger volume range.

- Metal Plunger

- Offers enhanced durability and a smooth – gliding action. The metal construction can withstand higher pressures, making it suitable for injecting viscous substances, such as some types of dermal fillers or thick medications. It provides a tight seal within the glass barrel, preventing leakage during injection.

- The metal plunger is often made of high – quality stainless steel, which is resistant to corrosion and can maintain its performance over multiple uses (in the case of prefilled syringes with proper handling).

- Plastic Plunger

- Lightweight and cost – effective. The plastic plunger is also designed to provide a good seal within the barrel. It is suitable for less viscous substances and is a popular choice for applications where a lighter touch is required.

- Made from medical – grade plastic, it is biocompatible and does not react with the substances inside the syringe. The plastic material can be molded to fit the user’s hand comfortably, providing ease of use.

- Glass Barrel: The syringes are made from high – quality medical – grade glass, which is known for its chemical inertness. This means that the glass does not interact with the substances inside the syringe, ensuring the integrity of the medication or cosmetic product. The glass is also break – resistant to a certain extent, although proper handling is still required.

- Sterility: All our prefilled glass syringes are sterilized using advanced techniques, such as ethylene oxide sterilization or gamma – irradiation. Each syringe is individually packaged to maintain sterility until use, ensuring a safe and contamination – free injection or application.

- Medical Applications: These syringes are widely used in hospitals, clinics, and medical research facilities. They are essential for accurate drug administration, sample collection, and wound care procedures. The variety of capacities and plunger options makes them suitable for different medical specialties, from general practice to specialized fields like dermatology and plastic surgery.

- Cosmetic Applications: In the cosmetic industry, these syringes are used by aestheticians and plastic surgeons for various procedures. Whether it’s injecting dermal fillers, botulinum toxin, or other cosmetic substances, the precision and quality of our syringes ensure optimal results. The different capacities allow for customized treatment plans based on the patient’s needs.

Introduction Of Prefilled Syringes

Prefilling syringes are usually used for biologics and other expensive drug products because prefilling syringes can reduce drug consumption.

Compared with filling the medicine in a vial and then withdrawing it with a syringe, the medicine is directly filled in the syringe, which is not only convenient to use, but also avoids the trouble of handling the drug residue in the vial which reduces the risk of contamination and is more environmentally friendly. The particularity of preloaded syringe makes challenging to manufacture.

1. Introduction

1. Introduction