As a professional medical device manufacturer, we understand the urgent needs of the modern healthcare industry for safe, convenient, and precise drug delivery solutions. Pre-filled syringes, as an innovative technology, are redefining the standards of medical injection. This article will provide an in-depth analysis of the core advantages of pre-filled syringes and their important value in modern healthcare systems from multiple dimensions.

Historical Development: Evolution from Traditional Injection to Smart Drug Delivery

Early Development Phase (1950s-1970s)

The concept of pre-filled syringes can be traced back to the 1950s. At that time, the medical industry began to realize that traditional glass ampoules and on-site drug preparation had many limitations. In 1957, the first batch of commercial pre-filled syringes appeared in Europe, mainly used for vaccination, marking the beginning of the modern injection technology revolution.

Key Point: Early pre-filled syringes solved two core problems: reducing preparation time for healthcare workers in emergency situations and lowering medical accident risks caused by human operational errors. However, limited by the material science and manufacturing technology of that time, early products still needed improvement in drug compatibility and long-term stability.

Technology Breakthrough Period (1980s-1990s)

Entering the 1980s, with the rapid development of biotechnology, especially the maturity of recombinant DNA technology and monoclonal antibody technology, the demand for high-quality drug packaging increased dramatically. During this period, pre-filled syringe technology achieved several key breakthroughs:

🔬 Material Science Progress: The standardized application of borosilicate glass solved the compatibility issues between drugs and containers, significantly improving product stability and reliability.

⚙️ Manufacturing Process Innovation: The introduction of automated filling technology made large-scale, high-precision production possible, significantly improving product quality control levels.

📋 Regulatory Framework Improvement: The FDA and European Medicines Agency successively established specialized regulatory frameworks for pre-filled syringes, laying the foundation for industry standardization.

Market Explosion Period (2000s-2010s)

At the beginning of the 21st century, pre-filled syringes entered a golden period of rapid development. Several key factors drove this development:

📈 Surge in Chronic Disease Treatment Demand: The dramatic increase in patients with diabetes, rheumatoid arthritis, and other chronic diseases created growing demand for convenient home self-administration.

💊 Biological Drug Market Boom: The widespread application of biological drugs such as insulin, growth hormones, and interferons raised higher requirements for precise dosing and drug stability.

💰 Cost Control Pressure: Rising healthcare costs prompted medical institutions to seek more efficient treatment solutions, and the economic benefits of pre-filled syringes gradually became apparent.

Smart Development Period (2010s-Present)

In the past decade, pre-filled syringe technology has entered a new stage of intelligent development:

🛡️ Safety Technology Upgrades: Needle stick protection technology, tamper-evident design, and traceability labeling have become standard features.

📱 Smart Drug Delivery Systems: Integration with electronic devices enables digital monitoring and data recording of the drug delivery process.

👤 Personalized Customization: Providing customized packaging solutions for different patient groups and special medication needs.

🌱 Environmental Sustainability: Using eco-friendly materials and developing recyclable packaging solutions to respond to global sustainable development trends.

📊 Market Data and Development Trends

According to industry research data, the global pre-filled syringe market grew from approximately $3 billion in 2010 to over $8 billion in 2023, maintaining a compound annual growth rate of 8-10%. The market size is expected to reach $15 billion by 2030.

This development process fully demonstrates the important transformation of pre-filled syringes from simple packaging improvements to core components of modern healthcare systems. As witnesses and participants in the industry, we deeply understand the medical demand drivers and technological innovation propulsion behind this technological evolution.

What: What Are Pre-filled Syringes?

Pre-filled syringes (PFS) are integrated injection devices that are filled with precise doses of medication before leaving the factory. Unlike traditional empty syringes that require on-site drug extraction, pre-filled syringes pre-package drugs in sterile environments, forming a complete drug delivery system.

🔍 Simple Explanation: Think of it like buying a ready-to-drink coffee instead of making coffee from scratch. Everything is already prepared and ready to use!

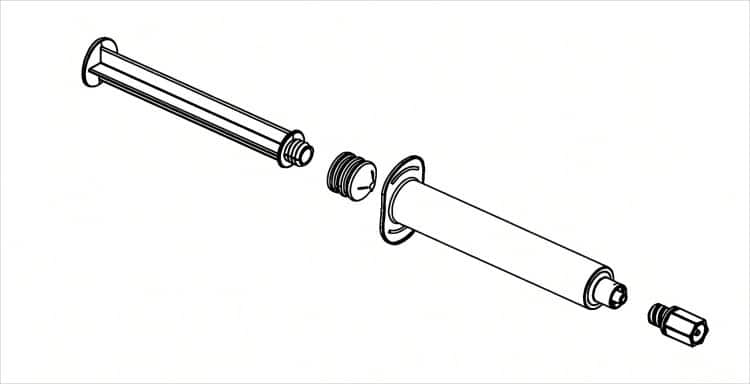

This innovative design includes the following core components:

- High-quality borosilicate glass or cyclic olefin copolymer (COC) syringe barrel

- Pre-filled precise dose medication

- Professionally designed rubber plunger system

- Safety needle or safety cap design

- Standard Luer connector compatibility

Why Do Pre-filled Syringes Have Significant Advantages?

1. 🛡️ Fundamental Protection of Patient Safety

❌ Eliminate Medication Error Risks: In traditional injection methods, healthcare workers need to extract drugs from vials, a process prone to dosage errors, drug contamination, or cross-infection. Pre-filled syringes eliminate these risks from the source through factory pre-filling in controlled sterile environments.

💉 Reduce Needlestick Injuries: Our pre-filled syringes feature advanced safety needle designs with automatic retraction or protective sleeve mechanisms, effectively reducing the risk of accidental needlestick injuries for healthcare workers, especially important when handling biologics or vaccines.

🏥 Real-World Impact: Studies show that pre-filled syringes can reduce medication errors by up to 85% and needlestick injuries by 70%.

2. 🧪 Technical Advantages of Drug Stability

⚗️ Optimized Material Compatibility: We use strictly validated borosilicate glass or high-performance plastic materials to ensure chemical compatibility with different drugs, maximally maintaining drug bioactivity and chemical stability.

📅 Extended Shelf Life: Through precision sealing technology and inert gas protection, pre-filled syringes can significantly extend drug shelf life, reduce drug waste, and lower healthcare costs.

💡 Easy Understanding: It’s like vacuum-sealed food that stays fresh longer compared to food in regular containers.

3. ⚡ Operational Convenience and Efficiency Improvement

🚀 Ready-to-Use Design: Healthcare workers don’t need complex drug preparation work – just tear open the package and use directly, dramatically improving work efficiency, especially suitable for emergency departments and large-scale vaccination scenarios.

📋 Standardized Operating Procedures: Unified operation steps reduce training costs, lower the possibility of operational errors, and ensure consistency and reliability of medical services.

⏰ Time Savings: Healthcare workers can save up to 3-5 minutes per injection compared to traditional methods.

4. 💰 Comprehensive Economic Benefits

🚫 Reduce Drug Waste: Precise pre-filled doses avoid the residual waste of traditional multi-dose vial drugs, especially in expensive biologics and specialty drug applications, where economic benefits are significant.

📉 Lower Overall Healthcare Costs: Although the unit cost may be slightly higher, the overall healthcare costs actually decrease through reduced preparation time, lower error rates, and reduced drug waste.

📊 Cost Analysis: While pre-filled syringes cost 10-15% more per unit, they can reduce total treatment costs by 20-25%.

How to Achieve the Technical Advantages of Pre-filled Syringes?

🏭 Advanced Manufacturing Processes

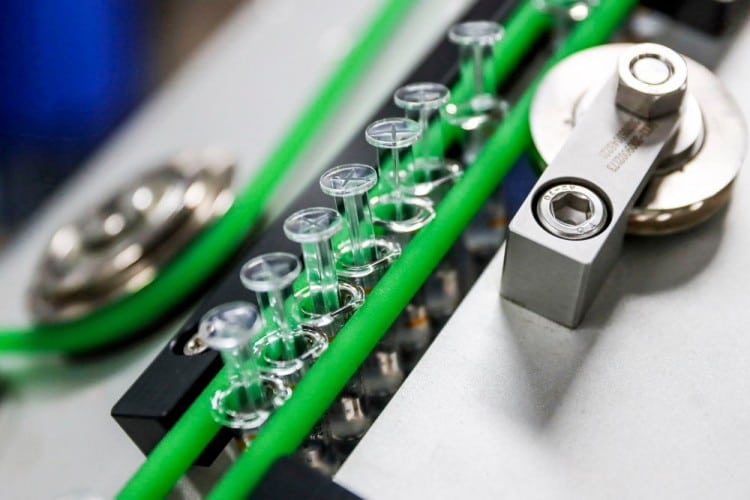

We use internationally leading automated production lines in ISO 15378 certified cleanroom environments. Every production step strictly follows GMP (Good Manufacturing Practice) standards, ensuring product quality consistency and reliability.

Key manufacturing technologies include:

- 🎯 High-precision liquid filling systems ensuring ±2% dosage accuracy

- 🧽 Advanced CIP/SIP (Clean-in-Place/Steam-in-Place) systems

- 🤖 Fully automated leak detection and visual inspection

- 📊 Real-time process parameter monitoring and data recording

✅ Strict Quality Control System

We have established a comprehensive quality management system covering the entire process from raw material procurement to finished product delivery:

📦 Raw Material Quality Control: All glass tubes, rubber stoppers, drugs, and other raw materials must pass strict incoming inspection, including chemical compatibility testing, microbial detection, and heavy metal content analysis.

🔄 Process Quality Control: Multi-point inspection during production, including filling accuracy checks, leak testing, visual inspection, etc., ensuring every product meets specifications.

🔬 Finished Product Inspection: Comprehensive quality verification before delivery, including sterility testing, endotoxin testing, particulate matter inspection, and stability testing.

🎨 Customized Solutions

As a professional manufacturer, we understand the special needs of different drugs and application scenarios:

🧬 Material Selection Optimization: Choose the most suitable container materials based on drug characteristics, such as COC materials for sensitive biologics and borosilicate glass for traditional chemical drugs.

📏 Specification Customization: Provide multiple specification options from 0.25ml to 20ml to meet different dosage requirements.

🔗 Compatibility Design: Ensure compatibility with mainstream injection equipment and auto-injectors for convenient medical institution equipment integration.

🚀 Application Prospects and Development Trends

Pre-filled syringes show strong development potential in the following areas:

💊 Biologics Field: With the rapid development of monoclonal antibodies, vaccines, insulin, and other biologics, pre-filled syringes have become the preferred packaging format.

🏠 Self-Administration Market: The home treatment needs of chronic disease patients drive the application of pre-filled syringes in the self-administration field.

🚨 Emergency and Mass Vaccination: In scenarios such as vaccine administration and emergency treatment, the convenience advantages of pre-filled syringes are more prominent.

🌐 Global Market Growth: The market is expected to grow at a 12-15% annual rate over the next five years.

🎯 Conclusion

Pre-filled syringes represent the development direction of modern medical injection technology. Through technological innovation, they effectively solve many pain points of traditional injection methods. As a professional manufacturer, we are committed to continuously improving product design and enhancing manufacturing process levels to provide safer, more convenient, and more economical injection solutions for global medical institutions.

In future medical development, pre-filled syringes will continue to play an important role in improving medical quality, ensuring patient safety, and enhancing medical efficiency. We believe that through continuous technological innovation and quality improvement, pre-filled syringes will become an indispensable important component of modern healthcare systems.

🔑 Key Takeaways:

- ✅ 85% reduction in medication errors

- ✅ 70% reduction in needlestick injuries

- ✅ 20-25% reduction in total treatment costs

- ✅ 3-5 minutes saved per injection

- ✅ Extended shelf life and improved drug stability

- ✅ Ready-to-use convenience for healthcare workers

- ✅ Growing market with 12-15% annual growth expected