Quick Navigation:

In precision fluid dispensing, syringes serve as critical tools across both healthcare and manufacturing sectors. While they may appear similar, industrial syringes and medical syringes differ significantly in design philosophy, manufacturing processes, and application requirements. This comprehensive guide explores these distinctions, helping you choose the right syringe solution for your needs.

Medical Syringes: Precision Instruments for Healthcare

Key Applications

Medical syringes are essential healthcare devices designed for:

Drug Administration: Delivering subcutaneous, intramuscular, and intravenous medications including vaccines, insulin, and antibiotics. Billions of injections worldwide rely on medical syringes annually.

Vaccination Programs: Critical for global immunization initiatives, single-use sterile medical syringes ensure safe vaccine delivery at scale.

Blood Collection: Specialized medical syringes meet stringent sterility requirements for diagnostic testing and blood sampling.

Chronic Disease Management: Insulin syringes enable daily diabetes treatment, with demand growing alongside the global diabetic population.

Critical Features

- Sterility Standards: Must meet rigorous medical-grade sterility through ethylene oxide or gamma irradiation sterilization

- Single-Use Design: Predominantly disposable to prevent cross-contamination

- Dosage Precision: Accurate graduations ensure correct medication dosing (±5% tolerance)

- Safety Mechanisms: Retractable needles and safety shields prevent needlestick injuries

- Biocompatible Materials: Medical-grade polypropylene, cyclic olefin polymers, or borosilicate glass ensure drug compatibility

Manufacturing Process for Medical Syringes

Medical syringe production demands exceptional quality control:

- Raw Material Selection: USP Class VI certified medical-grade polymers or pharmaceutical glass

- Injection Molding: High-precision molding in ISO Class 7 cleanrooms (10,000 particles/m³)

- Component Assembly: Automated assembly lines ensure consistent plunger-barrel fit

- Sterilization: Ethylene oxide gas or gamma radiation sterilization (25-50 kGy)

- Quality Testing: 100% visual inspection plus statistical sampling for:

- Sterility assurance (SAL 10⁻⁶)

- Dimensional accuracy (±0.1mm)

- Functionality testing (glide force, dead space)

- Packaging: Blister packs or peel pouches maintaining sterile barriers

- Regulatory Compliance: FDA 510(k) clearance, CE marking under MDR, ISO 7886 certification

Production Environment: ISO 13485 certified facilities with validated processes and extensive documentation.

Market Dynamics

The global syringe market reached $24.5 billion in 2024, projected to hit $63.4 billion by 2035 at a 9.0% CAGR, with medical syringes dominating market share.

Growth Drivers:

- Chronic Disease Prevalence: Diabetes patients projected to reach 783 million by 2045

- Vaccination Expansion: Ongoing global immunization programs, particularly mRNA vaccines

- Aging Demographics: Growing elderly population requiring injectable treatments

- Biologics Growth: Monoclonal antibodies and biologic drugs requiring specialized delivery

Market Segmentation:

- Disposable syringes: 89.23% market share (2024)

- Hospital end-users: 54.29% market share

- Diabetes management: 36.89% revenue share

- Prefilled syringes: 9.43% CAGR (fastest-growing segment)

Regional Distribution: North America leads with 39.44% market share, while Asia-Pacific shows fastest growth at 9.32% CAGR.

Pricing Structure for Medical Syringes

Medical syringe pricing varies by specifications:

- Standard disposable syringes (1-10ml): $0.05-0.20 per unit (bulk orders)

- Safety syringes: $0.15-0.50 per unit (20-150% premium)

- Insulin syringes: $0.10-0.30 per unit

- Prefilled syringes: $1.00-5.00 per unit (includes drug filling)

- Specialty syringes (glass, large volume): $0.50-2.00 per unit

Volume discounts typically range from 10-30% for orders exceeding 100,000 units.

Industrial Syringes: Precision Tools for Manufacturing

Key Applications

Industrial syringes excel in manufacturing environments:

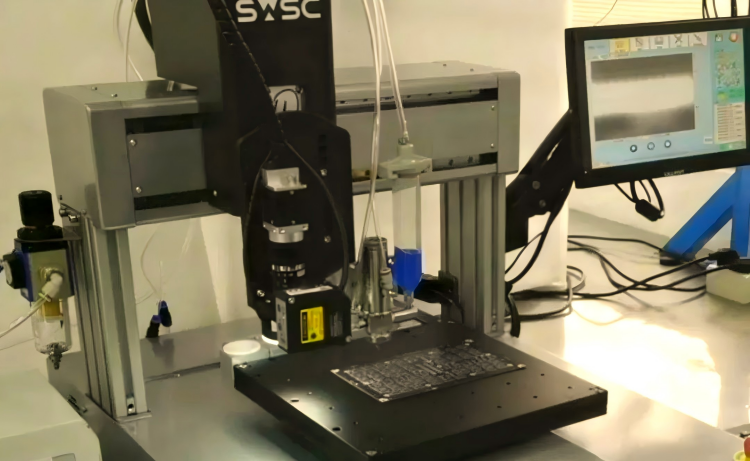

Precision Adhesive Dispensing: Electronics manufacturing, semiconductor packaging, and automotive assembly require precise epoxy, adhesive, and sealant distribution. Industrial syringes deliver exceptional repeatability.

Lubrication Distribution: Accurate lubricant and grease delivery during machinery maintenance and assembly.

Solder Paste Application: PCB assembly processes depend on industrial syringes for precise solder paste deposition—critical for electronic product quality.

UV-Curable Materials: Optical device manufacturing uses specialized light-blocking industrial syringes for UV adhesive dispensing.

Coatings and Sealing: Aerospace and automotive industries apply protective coatings and sealants using industrial syringes.

Laboratory Research: Chemical and biological research labs utilize industrial syringes for precise liquid handling and reagent dispensing.

Critical Features

- Chemical Compatibility: Resistant to industrial chemicals, including corrosive solvents and high-viscosity materials

- Viscosity Range: Handles materials from low-viscosity liquids to thick pastes (1-1,000,000 cP)

- Precision Control: Integrates with pneumatic/electric dispensing systems for microliter-level accuracy

- Reusable Design: Many industrial syringes feature washable, reusable construction for cost efficiency

- Specialized Configurations: Anti-static, UV-resistant, high-temperature designs for specific requirements

- Size Variety: 3cc to 55cc+ capacities with various dispensing tips and needle gauges

Manufacturing Process for Industrial Syringes

Industrial syringe production emphasizes durability and chemical resistance:

- Material Selection: Industrial-grade polymers (polypropylene, polyethylene, PTFE) or stainless steel

- Molding/Machining:

- Plastic syringes: Injection molding with tighter tolerances (±0.05mm)

- Metal syringes: CNC machining for high-pressure applications

- Surface Treatment:

- Plasma treatment for improved chemical resistance

- Silicone coating for smooth plunger action

- Anti-static coatings for electronics applications

- Assembly: Precision-fit plungers with O-rings or gaskets for leak-proof performance

- Quality Control:

- Dimensional verification (CMM inspection)

- Pressure testing (up to 100 PSI)

- Chemical compatibility testing

- Volumetric accuracy validation (±1%)

- Cleaning: Industrial cleaning protocols (ultrasonic or solvent cleaning)

- Packaging: Bulk packaging or individual wrapping (non-sterile)

Production Environment: Standard manufacturing facilities with quality management systems (ISO 9001).

Technical Advantages

Modern industrial syringe systems integrate:

- Digital Control: 0.001-second timing precision ensuring consistent dispensing

- Pressure Regulation: 0-100 PSI adjustable pressure for varying viscosities

- Automation Integration: Robotic system compatibility for automated production lines

- Multi-Mode Operation: Manual, incremental, and timed (automatic) dispensing modes

Market Characteristics

While industrial syringes lack standalone market statistics, they’re integral to industrial automation and precision manufacturing equipment markets:

Growth Drivers:

- Electronics Manufacturing: Sustained demand for smartphones, wearables, and IoT devices

- Automation Trends: Manufacturing automation increasing demand for precision dispensing systems

- Electric Vehicles: EV battery assembly requiring extensive adhesive bonding and sealing

- Aerospace: High-end manufacturing demanding precision material application

- Medical Device Production: Precision assembly requirements in device manufacturing

Pricing Structure for Industrial Syringes

Industrial syringe pricing reflects durability and specialization:

- Standard disposable (3-30cc): $0.20-1.00 per unit

- Reusable syringes (plastic): $2.00-10.00 per unit

- Stainless steel syringes: $15.00-50.00 per unit

- Specialty syringes (UV-resistant, anti-static): $5.00-25.00 per unit

- Complete dispensing systems: $500-5,000+ (including controller and syringe)

Cost-per-use for reusable industrial syringes can be 10-50 times lower than disposables over their lifetime.

Critical Differences: Medical vs Industrial Syringes

| Comparison Factor | Medical Syringes | Industrial Syringes |

|---|---|---|

| Primary Use | Drug injection, vaccination | Adhesive dispensing, lubrication |

| Sterility | Mandatory medical-grade sterility | Generally non-sterile, cleanliness-focused |

| Usage | Predominantly single-use | Reusable or disposable |

| Precision | Drug dosage accuracy (±5%) | Dispensing accuracy (±1% or better) |

| Materials | Medical-grade plastic/glass | Industrial-grade plastic, chemical-resistant |

| Regulatory Oversight | Strict FDA/CE certification | Industrial standards, less stringent |

| Manufacturing Environment | ISO Class 7 cleanrooms | Standard manufacturing facilities |

| Sterilization | Required (EtO/gamma) | Not required |

| Unit Cost | $0.05-5.00 | $0.20-50.00+ |

| Quality Testing | 100% inspection + sampling | Statistical sampling |

| Documentation | Extensive validation records | Standard quality records |

| System Integration | Typically standalone | Often automated system integration |

| Environment | Clinical settings | Industrial production environments |

Production Cost Analysis

Medical Syringe Cost Breakdown

- Raw materials: 35-45%

- Manufacturing/assembly: 20-30%

- Sterilization: 10-15%

- Quality control/testing: 8-12%

- Packaging: 5-8%

- Regulatory compliance: 5-10%

Industrial Syringe Cost Breakdown

- Raw materials: 40-50%

- Manufacturing/machining: 25-35%

- Quality control: 5-8%

- Surface treatment: 3-7%

- Packaging: 2-5%

- Standards compliance: 2-5%

Key Difference: Medical syringes carry significantly higher regulatory and sterilization costs, while industrial syringes invest more in durable materials and precision manufacturing.

Future Trends

Medical Syringes

- Smart Technology: Integrated sensors and digital connectivity for medication tracking

- Self-Administration: Proliferation of prefilled and auto-injectors for home use

- Sustainable Materials: Biodegradable options reducing medical waste environmental impact

- Needle-Free Systems: Jet injection technology minimizing pain and needlestick risks

- Biologics Optimization: Advanced materials preventing biologic drug degradation

Industrial Syringes

- Industry 4.0 Integration: Data collection and quality traceability for smart manufacturing

- Miniaturization: Ultra-precision dispensing for microelectronics and precision device manufacturing

- Multifunctional Design: Integrated heating, cooling, and UV curing capabilities

- Sustainability: Efficient cleaning systems for reusable syringes reducing waste

- AI Optimization: Machine learning optimizing dispensing parameters for enhanced efficiency

Choosing the Right Syringe Manufacturers

Whether for medical or industrial applications, selecting appropriate syringe manufacturers is crucial. Key considerations include:

- Quality Certifications: Verify products meet relevant industry standards (ISO 13485 for medical, ISO 9001 for industrial)

- Customization Capabilities: Ability to tailor products to specific application requirements

- Technical Support: Application engineering support and troubleshooting assistance

- Supply Reliability: Consistent supply capacity and delivery timelines

- Cost-Effectiveness: Competitive pricing while maintaining quality standards

- Manufacturing Capacity: Scalability to meet growing demand

- R&D Investment: Innovation capabilities for emerging applications

Kohope: Your Trusted Partner in Syringe Manufacturing

As a professional syringe manufacturer, Kohope brings decades of expertise in delivering high-quality, high-performance syringe solutions for medical and industrial clients worldwide.

Our Competitive Advantages

Medical-Grade Quality Assurance: Our medical syringes comply with ISO 13485 quality management systems, featuring CE certification and FDA registration. From raw material selection through production control to final inspection, we implement comprehensive quality management ensuring every syringe meets international medical device standards.

Industrial Application Expertise: For diverse industrial needs, we provide various specifications and materials of industrial syringes suitable for adhesive dispensing, lubrication delivery, and precision dot applications. Our products deliver exceptional chemical resistance and dimensional accuracy, meeting the most demanding industrial requirements.

Customization Services: With a robust R&D team and flexible production capabilities, we offer customized products and solutions tailored to special customer requirements. Whether special materials, unique specifications, or custom packaging, we accommodate your needs.

Continuous Innovation: We closely monitor industry trends, continuously investing in R&D innovation to develop prefilled syringes, safety syringes, and other advanced products, leading industry technological progress.

Global Service Network: Through comprehensive supply chain management and logistics systems, we provide timely, reliable product delivery and technical support to global customers.

Why Choose Kohope as Your Syringe Manufacturer?

- ✓ 20+ Years Industry Experience: Deep technical expertise and rich application knowledge

- ✓ ISO-Certified Production: Modern manufacturing facilities meeting international quality standards

- ✓ Complete Product Range: 1ml to 60ml, covering full medical and industrial product lines

- ✓ Rapid Response: Professional technical team providing 24/7 customer support

- ✓ Competitive Pricing: Cost advantages from large-scale production

- ✓ Sustainable Development: Eco-friendly materials and green manufacturing processes

- ✓ Proven Track Record: Trusted by leading healthcare providers and manufacturers globally

Partner With Leading Syringe Manufacturers

Whether you need medical syringes or industrial syringes, standard products or custom solutions, Kohope stands ready as your ideal manufacturing partner.

Visit Our Website for comprehensive product information and solutions: www.kohope.com

Contact Our Sales Team for professional consultation and quotations: sales@kohope.com

Follow Our Social Media for latest industry insights and product updates

Choose Kohope—choose quality and professionalism. Let’s work together to advance healthcare and industrial manufacturing excellence!

Data sourced from publicly available market research reports for reference purposes. For specific product specifications and application recommendations, please consult Kohope’s professional team.