As a leading insulin syringe manufacturer, we understand that proper syringe usage is absolutely critical for diabetes management success. This comprehensive guide provides evidence-based recommendations and best practices to ensure safe, effective, and accurate insulin delivery for healthcare professionals and patients alike.

1. Selecting the Right Syringe Specifications

Capacity Selection Based on Patient Needs

Choosing the appropriate syringe capacity is fundamental to accurate dosing and patient compliance:

- 🔹 0.3mL Syringes: Ideal for patients requiring low-dose insulin therapy (typically <30 units daily)

- Enhanced accuracy for pediatric patients

- Reduced dead space minimizes insulin waste

- Easier handling for patients with dexterity challenges

- 🔹 0.5mL Syringes: Perfect for moderate-dose requirements (30-50 units)

- Balanced capacity and precision

- Most commonly prescribed size

- Optimal for standard adult therapy

- 🔹 1.0mL Syringes: Designed for high-dose insulin regimens (>50 units)

- Reduces injection frequency

- Cost-effective for high-volume users

- Suitable for concentrated insulin formulations

Needle Specifications: Precision Matters

Modern needle technology focuses on patient comfort and injection accuracy:

- Needle Length: 4-8mm short needles are now the gold standard

- Significantly reduces risk of intramuscular injection

- Minimizes injection anxiety, especially in children

- Suitable for 95% of adult patients regardless of BMI

- Needle Gauge: 31-32G ultra-fine needles provide optimal balance

- Reduces injection pain by up to 40%

- Maintains proper insulin flow dynamics

- Prevents needle bending during injection

Graduation Accuracy Standards

Precision manufacturing ensures dosing reliability:

- Clear, high-contrast scale markings

- Graduated increments appropriate for prescribed doses

- Enhanced visibility for patients with visual impairments

- ±2% accuracy tolerance meeting FDA requirements

2. Ensuring Sterility and Single-Use Compliance

Sterility Verification Protocol

Pre-use inspection is non-negotiable for patient safety:

✅ Package Integrity Check

- Verify tamper-evident seals are intact

- Confirm sterilization indicators show proper processing

- Check for any visible cracks or defects in packaging

✅ Expiration Date Validation

- Never use expired products

- Implement FIFO (First In, First Out) inventory management

- Document expiration dates for quality control

Strict Single-Use Policy

One syringe, one injection, one patient – this principle saves lives:

- Zero tolerance for reuse: Even with the same patient, reuse increases infection risk by 300%

- Cross-contamination prevention: Shared syringes can transmit bloodborne pathogens

- Needle degradation: Reused needles become duller, causing increased tissue trauma

Immediate Use Protocol

Once opened, syringes must be used immediately to maintain sterility:

- Maximum 15-minute exposure time after package opening

- Avoid leaving syringes in non-sterile environments

- Discard any syringe that contacts non-sterile surfaces

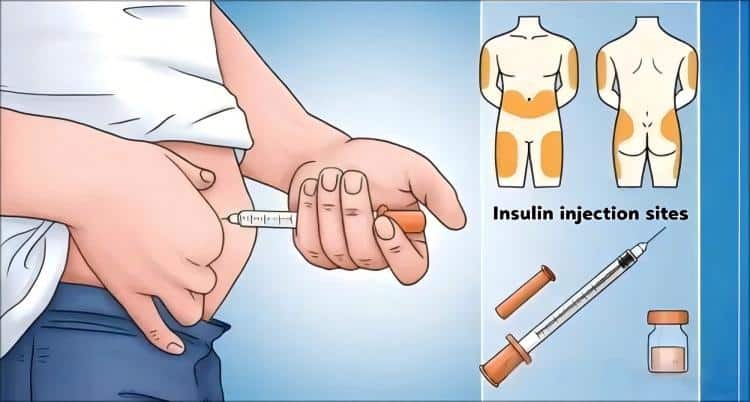

3. Optimal Injection Site Selection and Rotation

Preferred Injection Sites with Absorption Rates

Strategic site selection optimizes insulin pharmacokinetics:

🎯 Abdomen (Fastest absorption – 100% baseline)

- Primary site for rapid-acting insulin

- Avoid 2-inch radius around navel

- Most consistent absorption patterns

🎯 Lateral Thigh (Moderate absorption – 70% of abdomen)

- Ideal for long-acting insulin

- Outer third of anterior thigh

- Good option for self-injection

🎯 Upper Arm (Variable absorption – 85% of abdomen)

- Posterior aspect of upper arm

- Requires assistance for proper injection

- Alternative site for rotation

🎯 Buttocks (Slowest absorption – 60% of abdomen)

- Reserved for long-acting formulations

- Upper outer quadrant only

- Professional administration recommended

Scientific Rotation Strategy

Systematic rotation prevents lipodystrophy and ensures consistent absorption:

- Site-to-site rotation: Change injection regions weekly

- Within-site spacing: Maintain minimum 1-inch separation between injection points

- Digital mapping: Use smartphone apps or charts to track injection sites

- 4-week cycle: Complete rotation cycle every 28 days

Avoiding Problematic Areas

Never inject in areas with:

- Lipodystrophy (fat lumps or depressions)

- Active infections or inflammation

- Scar tissue or moles

- Areas with altered sensation

4. Achieving Dosing Accuracy Excellence

The Triple-Check System

Error prevention through systematic verification:

- Initial Check: Verify prescription against insulin vial

- Drawing Check: Confirm dose measurement in syringe

- Final Check: Re-verify dose before injection

Professional Drawing Technique

Precision drawing ensures accurate dosing:

🔸 Vertical positioning: Keep syringe perpendicular during drawing

🔸 Controlled aspiration: Draw slowly to prevent air bubble formation

🔸 Meniscus reading: Align bottom of liquid curve with graduation mark

🔸 Air bubble elimination: Tap syringe gently, then expel air completely

Advanced Dosing Considerations

- Temperature correction: Allow refrigerated insulin to reach room temperature

- Mixing protocols: Follow specific sequences for combination insulins

- Concentration verification: Always confirm insulin strength (U-100, U-40, etc.)

- Dose timing: Coordinate injection with meal timing for optimal glycemic control

5. Infection Control and Safety Protocols

Hand Hygiene Excellence

Proper hand hygiene reduces infection risk by 85%:

- 20-second wash rule: Use soap and warm water

- Alcohol-based sanitizer: 70% alcohol minimum concentration

- Complete coverage: Include fingertips, between fingers, and wrists

- Air dry: Avoid towel contamination

Injection Site Preparation

Professional antiseptic technique:

- Clean site selection: Choose area free from visible contamination

- Circular antiseptic application: Start from center, spiral outward

- Drying time: Allow 30-second evaporation before injection

- No recontamination: Avoid touching cleaned area

Safe Injection Technique

Optimal injection methodology:

- Angle selection: 90° for most patients, 45° for very thin individuals

- Steady insertion: Quick, confident needle insertion

- Controlled delivery: Inject at 1-2 units per second

- Post-injection hold: Maintain needle position for 10 seconds minimum

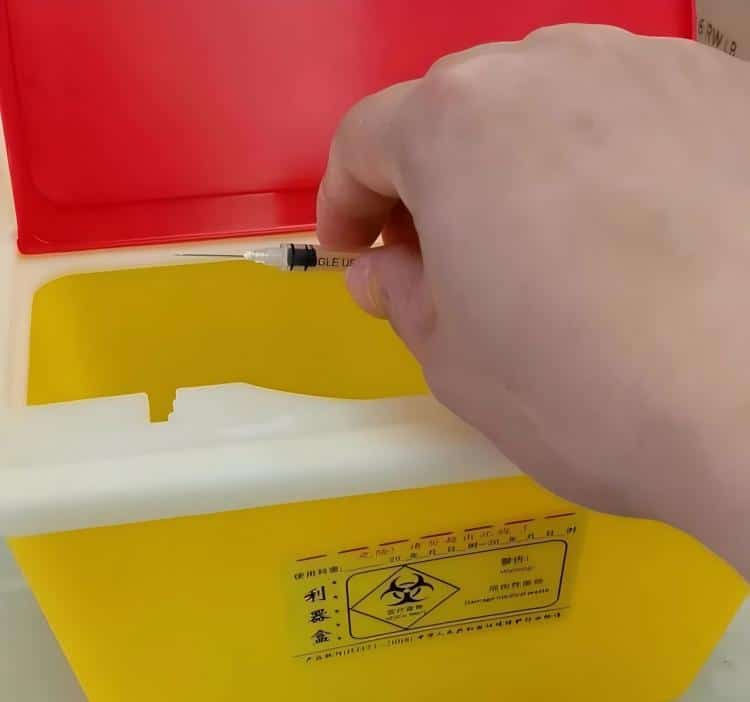

6. Responsible Medical Waste Management

Immediate Disposal Protocol

Safe disposal protects healthcare workers and the environment:

⚠️ Never recap needles – leading cause of needlestick injuries

⚠️ Immediate container placement – dispose within 60 seconds of use

⚠️ Puncture-resistant containers – use FDA-approved sharps containers only

Home Disposal Solutions

Patient-friendly disposal options:

- Mail-back programs: Pharmaceutical company-sponsored collection

- Community drop-off sites: Hospital and pharmacy collection points

- Household alternatives: Rigid plastic containers (laundry detergent bottles)

- Never use: Regular trash, recycling bins, or toilet disposal

Environmental Stewardship

Our commitment to sustainable healthcare:

- Biodegradable packaging materials where possible

- Syringe take-back programs for large-volume users

- Partnership with certified medical waste processors

- Carbon-neutral shipping for bulk orders

7. Advanced Best Practices and Quality Assurance

Storage and Inventory Management

Optimal storage conditions maintain product integrity:

- Temperature control: 68-77°F (20-25°C) ambient storage

- Humidity management: <60% relative humidity

- Light protection: Store in original packaging away from UV exposure

- Inventory rotation: First-in, first-out systematic usage

Patient Education Excellence

Comprehensive training programs improve outcomes:

📚 Initial Certification Program

- 2-hour hands-on training session

- Competency verification testing

- Take-home reference materials

- Emergency contact information

📚 Ongoing Education

- Quarterly skill refresh sessions

- New product training updates

- Peer support group facilitation

- Digital learning platforms

Quality Monitoring Systems

Continuous improvement through data collection:

- Adverse event tracking: Real-time reporting system

- Patient satisfaction surveys: Monthly feedback collection

- Clinical outcome correlation: HbA1c improvement tracking

- Product performance analytics: Usage pattern analysis

Emergency Response Protocols

Crisis management for injection-related incidents:

🚨 Needlestick Injury Protocol

- Immediate wound care and bleeding encouragement

- Antiseptic application and wound covering

- Incident documentation and reporting

- Follow-up medical evaluation within 24 hours

🚨 Overdose Management

- Immediate blood glucose monitoring

- Fast-acting carbohydrate administration

- Emergency medical services activation if unconscious

- Continuous monitoring until medical help arrives

🚨 Allergic Reaction Response

- Discontinue injection immediately

- Assess severity using standardized scale

- Administer antihistamines for mild reactions

- Call emergency services for severe reactions

Conclusion: Excellence in Diabetes Care

The proper use of insulin syringes represents a critical intersection of medical technology, patient safety, and therapeutic efficacy. As a premier manufacturer, we recognize that our responsibility extends far beyond producing high-quality devices – we are partners in the comprehensive care of diabetes patients worldwide.

Key success factors for optimal insulin syringe usage include:

✅ Precision in selection – matching device specifications to patient needs

✅ Uncompromising sterility – maintaining the highest safety standards

✅ Strategic injection planning – optimizing absorption and minimizing complications

✅ Accuracy obsession – ensuring every dose delivers therapeutic intent

✅ Safety-first protocols – protecting patients, caregivers, and communities

✅ Environmental responsibility – sustainable disposal and waste management

Our commitment to continuous innovation drives us to develop next-generation solutions that address emerging challenges in diabetes care. Through collaborative partnerships with healthcare providers, patients, and researchers, we strive to advance the standard of care and improve quality of life for millions of diabetes patients globally.

Remember: Every injection matters. Every safety protocol saves lives. Every properly disposed syringe protects our environment. Together, we can achieve excellence in diabetes management through meticulous attention to detail and unwavering commitment to patient safety.

For technical support, clinical guidance, or product information, contact our 24/7 Professional Support Line or visit our digital resource center for the latest evidence-based protocols and training materials.