Description

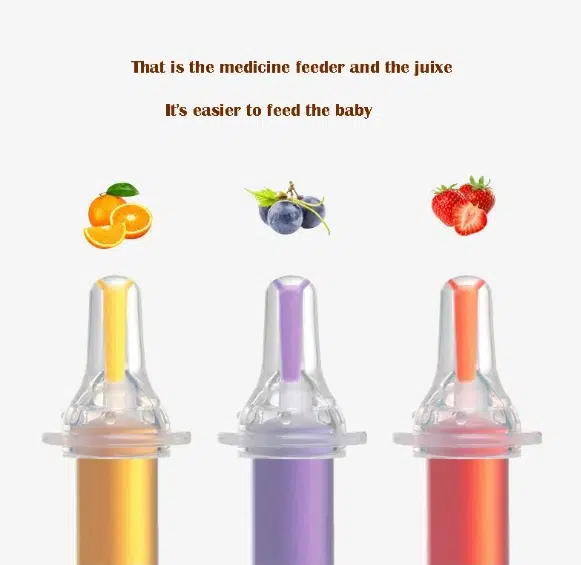

Our food syringe with silicone pacifier attachment represents the industry’s leading solution for infant medication and nutrition delivery. This specialized catheter for food administration combines pharmaceutical-grade accuracy with baby-centered ergonomic design, making it the preferred choice for distributors serving pediatric care markets.

![]()

Core Product Specifications

Design Innovation The integrated food catheter mechanism utilizes medical-grade silicone construction throughout the pacifier interface, ensuring both safety compliance and infant comfort. Each food syringe features precision measurement markings calibrated for exact dosing, eliminating guesswork in medication or supplement administration. The patented dual-function design allows the unit to operate as both a familiar pacifier and an efficient delivery system for liquid medications or nutrition supplements.

Material Excellence Every component undergoes rigorous food-safety certification processes. Our catheter for food syringe products utilize FDA-approved, BPA-free silicone and medical-grade plastics that meet international baby product standards. The soft-touch food catheter tip provides gentle oral contact while maintaining structural integrity through repeated sterilization cycles.

Customization Capabilities for B2B Clients

Brand Integration Services

Visual Customization

- Custom color matching for food syringe bodies (Pantone specification supported)

- Logo printing on syringe barrel and packaging

- Private label design for catheter for food products

- Custom measurement marking styles and increments

Packaging Solutions

- Retail-ready blister packaging with branded inserts

- Bulk packaging options for rebranding operations

- Multi-unit gift sets featuring food syringe combinations

- Customized instruction manuals in multiple languages

Technical Modifications

Our engineering team accommodates specification adjustments to food catheter dimensions, capacity volumes (5ml to 15ml range), and pacifier nipple variations to match regional preferences or specific market requirements.

Quality Assurance & Compliance

Manufacturing Standards

Triple-Layer Quality Control

- Raw Material Inspection: All silicone and plastic components for our catheter for food syringe undergo SGS certification verification

- In-Line Testing: Three quality checkpoints during food syringe assembly monitor dimensional accuracy and functionality

- Pre-Shipment Validation: 100% final inspection ensures every food catheter unit meets specifications

Certifications Available

- FDA Food Contact Compliance

- EN14350 European Baby Product Standards

- CPSIA (Consumer Product Safety Improvement Act)

- SGS Material Safety Documentation

- ISO 9001:2015 Manufacturing Certification

B2B Partnership Advantages

Production Capacity

Our dedicated food syringe production lines maintain output capacity of 500,000+ units monthly, ensuring reliable supply for large-scale distribution agreements. The 50,000-unit minimum order quantity enables competitive per-unit pricing while maintaining premium quality standards for your catheter for food product inventory.

Supply Chain Efficiency

Lead Times:

- Standard food syringe orders: 15-20 business days

- Custom catheter for food syringe specifications: 25-35 business days

- Rush production available for qualified bulk orders

Logistics Support:

- DHL/UPS/FedEx express shipping (4-6 days door-to-door)

- Air freight consolidation for cost optimization

- Sea freight coordination for maximum volume orders

- Warehousing solutions for ongoing distribution partnerships

Product Applications & Market Positioning

Primary Use Cases

This food catheter system serves multiple pediatric care scenarios:

- Medication Administration: Precise delivery of liquid antibiotics, pain relievers, and supplements through the food syringe mechanism

- Nutritional Support: Introducing pureed foods and vitamin solutions via the gentle catheter for food design

- Hydration Management: Controlled fluid intake for infants resistant to traditional bottles

- Special Needs Care: Assistive feeding for babies with swallowing difficulties

Target Customer Segments

- Pharmacy chains requiring branded food syringe products

- Baby care retailers seeking exclusive catheter for food items

- Hospital supply distributors needing medical-grade solutions

- E-commerce brands building pediatric product catalogs

- International importers serving emerging baby care markets

Technical Specifications Summary

| Feature | Specification |

|---|---|

| Capacity | 10ml (customizable 5ml-15ml) |

| Material | FDA-approved silicone + medical-grade PP |

| Measurement Accuracy | ±0.2ml precision markings |

| Pacifier Nipple | Orthodontic design, multiple flow rates |

| Sterilization | Autoclave safe up to 120°C |

| Package Dimensions | Customizable per order volume |

| Shelf Life | 3 years from manufacture date |

Why Choose Kohope as Your Manufacturing Partner

Industry Expertise

With over 12 years specializing in infant feeding solutions, our food syringe and catheter for food products reflect deep understanding of both regulatory requirements and end-user needs. We’ve supported 200+ brands globally in launching successful baby care product lines.

Flexible Collaboration Models

OEM Services: Manufacture to your exact food catheter specifications with neutral branding ODM Solutions: Leverage our design expertise to create unique catheter for food syringe variations Hybrid Partnerships: Combine our standard food syringe platform with your brand elements

Post-Production Support

- Dedicated account management for large-volume clients

- Technical documentation assistance for market certification

- Marketing asset provision (product photography, specification sheets)

- Quality guarantee with replacement policy for defective units

Getting Started: Your Custom Order Process

Step 1: Submit your food syringe customization requirements and target quantity Step 2: Receive detailed quotation with MOQ pricing tiers (50,000+ units) Step 3: Approve samples of your branded catheter for food products Step 4: Confirm production timeline and logistics preferences Step 5: Receive quality-certified shipment with full documentation

Contact Information for B2B Inquiries

Ready to discuss your food catheter customization project? Our business development team specializes in supporting medium to large-scale distributors with tailored food syringe solutions.

Minimum Order Quantity: 50,000 units Sample Availability: Stock samples (3-4 days) | Custom samples (10-15 days) Payment Terms: Flexible options for qualified bulk buyers

Elevate your baby care product portfolio with Kohope’s precision-engineered food catheter systems. Contact us today to explore customization possibilities for your market.