Description

WHAT – Complete Product Range

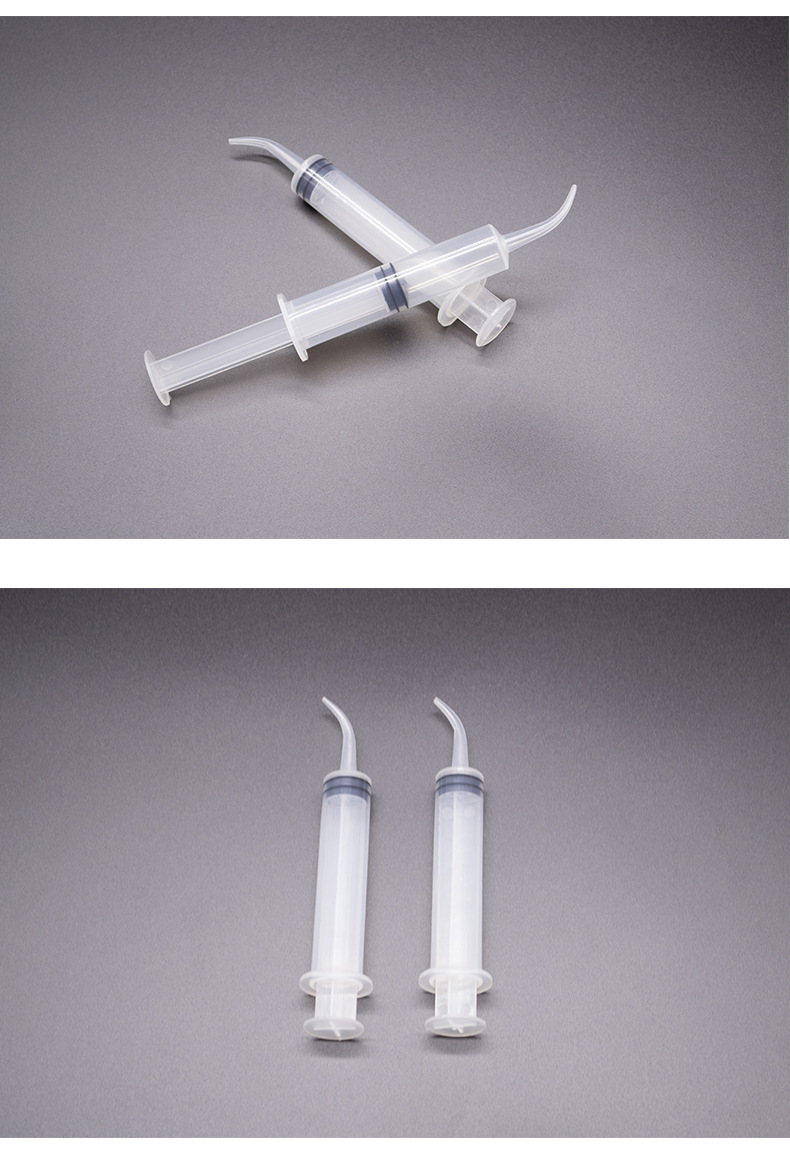

Our comprehensive animal feeding syringes collection includes:

- Precision Bird Syringes: Available in 1ml, 5ml, 10ml, 20ml, 30ml, 60ml, and 100ml capacities

- Complete Feeding Kits: Combining multiple bird feeding syringe sizes with soft feeding spoons

- Specialized Nozzles: Curved, straight, and flexible tips designed for various bird species

- Accessory Components: Replacement plungers, feeding tubes, and sterilization cases

Detailed Capacity Specifications:

| Capacity | Barrel Length | Outer Diameter | Graduation Interval | Nozzle Type | Weight |

|---|---|---|---|---|---|

| 1ml | 55mm | 8mm | 0.1ml | Straight 2mm | 3g |

| 5ml | 75mm | 12mm | 0.2ml | Straight/Curved 3mm | 6g |

| 10ml | 90mm | 15mm | 0.5ml | Straight/Curved 3mm | 9g |

| 20ml | 110mm | 19mm | 1ml | Straight/Curved 5mm | 14g |

| 30ml | 120mm | 21mm | 1ml | Straight/Curved 5mm | 18g |

| 60ml | 145mm | 26mm | 2ml | Straight/Curved 8mm | 28g |

| 100ml | 170mm | 32mm | 5ml | Straight/Curved 8mm | 42g |

Advanced Design Features:

- Ergonomic Finger Grips: Textured surface with 1.5mm raised patterns for secure handling

- Anti-Slip Plunger: Rubberized thumb rest with 15mm diameter contact area

- Large Number Markings: 3mm height graduations with 0.3mm embossed depth

- Color-Coded Options: Available in clear, blue-tinted, amber (light-sensitive formulas)

- Luer Lock Compatibility: Optional luer lock tip for secure feeding tube attachment

- Flow Rate Control: Adjustable plunger resistance mechanism (patent pending)

Each bird syringe features graduated measurement markings for accurate dosing, smooth plunger operation for controlled feeding, and medical-grade materials meeting international safety standards.

Technical Specifications:

- Material Composition: Medical-grade polypropylene (PP) barrel, silicone rubber plunger seal, TPE soft feeding tips

- Temperature Resistance: -20°C to +120°C (autoclavable at 121°C for 15 minutes)

- Measurement Accuracy: ±2% deviation tolerance across all capacity ranges

- Barrel Transparency: >92% light transmittance for clear content visibility

- Plunger Force: 3-5N smooth operation force, preventing hand fatigue during repeated feeding

- Wall Thickness: 1.2-1.8mm barrel wall ensuring durability without excessive weight

- Nozzle Diameter Options: 2mm, 3mm, 5mm, 8mm openings for different formula viscosities

- Sterilization Methods: Steam autoclave, ethylene oxide (ETO), gamma radiation compatible

- Shelf Life: 5 years under proper storage conditions (sealed, room temperature, away from direct sunlight)

WHO – Target B2B Customer Groups

Our bird feeding syringe solutions serve:

- E-commerce Sellers: Amazon FBA sellers, eBay stores, and independent pet supply websites requiring white-label or branded products

- Wholesale Distributors: Regional and national distributors seeking reliable inventory for pet store networks

- Veterinary Suppliers: Medical equipment companies serving avian veterinarians and wildlife rehabilitation centers

- Breeding Operations: Commercial parrot breeders, poultry farms, and aviculture facilities needing bulk animal feeding syringes

- Retail Chains: Pet supermarkets and specialty bird shops requiring consistent product supply

WHERE – Global Manufacturing & Distribution

Manufacturing Excellence: Our ISO-certified production facility in China employs automated molding systems and multi-stage quality inspection. Every bird feeding syringe undergoes pressure testing, measurement verification, and material safety analysis before packaging.

Manufacturing Technical Details:

- Production Capacity: 500,000 units/month across all bird syringe sizes

- Injection Molding Machines: 28 units ranging from 80-ton to 350-ton clamping force

- Cycle Time: 18-35 seconds per unit depending on capacity

- Mold Cavities: 4-cavity to 16-cavity configurations for efficient production

- Quality Inspection Rate: 100% visual inspection + 10% dimensional verification sampling

- Clean Room Standards: ISO Class 8 (Class 100,000) production environment

- Automated Assembly: Robotic systems for plunger insertion and packaging (99.8% accuracy)

- Testing Equipment: CMM coordinate measuring machines, tensile testing apparatus, leak detection systems

- Traceability: Batch numbering system with production date, shift, and machine identification

- Certifications: ISO 9001:2015, ISO 13485:2016 medical device quality management

Worldwide Shipping: We maintain strategic partnerships with international logistics providers, offering:

- FOB, CIF, and DDP shipping terms

- Consolidated shipping for mixed orders

- Express delivery options for sample orders

- Custom packaging and labeling at origin

Market Reach: Our bird syringe products currently serve clients in North America, Europe, Australia, Japan, and emerging markets across Southeast Asia and Latin America.

WHEN – Order Fulfillment & Delivery Timeline

- Sample Orders: 3-5 business days production + shipping time

- Standard Wholesale Orders (500-5,000 units): 7-12 business days

- Bulk Custom Orders (5,000+ units): 15-25 business days

- Repeat Orders: Priority production queue with 5-10 business day turnaround

Seasonal Planning: We recommend placing orders for animal feeding syringes 4-6 weeks before peak seasons (spring breeding season, holiday gift periods) to ensure adequate inventory.

WHY – Kohope Competitive Advantages

Superior Quality Materials: Our bird feeding syringes use medical-grade polypropylene (PP) and silicone components, free from BPA, phthalates, and harmful plasticizers. Materials meet FDA, EU, and LFGB food contact standards.

Detailed Material Certifications:

- FDA 21 CFR 177.1520: Food contact approved polypropylene

- EU Regulation 10/2011: Compliant with European plastic food contact materials

- LFGB (Germany): Tested and certified for food safety

- RoHS Directive: Lead, mercury, cadmium free (<0.01% concentration)

- REACH Compliance: All 233 SVHC substances within safe limits

- USP Class VI Biocompatibility: Cytotoxicity, sensitization, and irritation tested

- ISO 10993 Medical Device Testing: Biological evaluation completed

Production Quality Control Parameters:

- Injection Molding Precision: ±0.05mm dimensional tolerance

- Surface Finish: Ra 0.4μm smoothness preventing bacterial adhesion

- Concentricity: <0.1mm barrel-to-plunger alignment deviation

- Printing Durability: Graduation markings withstand 500+ cleaning cycles without fading

- Leak Test: 100% units pressure tested at 50kPa for 30 seconds

- Drop Test Resistance: Survives 1.5m drops onto concrete surface

- Tensile Strength: Barrel withstands 180N force without cracking

Precision Engineering: Advanced injection molding technology ensures:

- Clear, permanent graduation markings

- Smooth barrel interiors preventing food residue buildup

- Leak-proof plunger seals maintaining suction integrity

- Consistent performance across production batches

Cost Efficiency: Direct manufacturer pricing eliminates middleman markups. Volume discounts scale from 15% (1,000 units) to 35% (50,000+ units). Our bird syringe pricing remains competitive without compromising quality.

Customization Capability:

- Private labeling with your brand logo

- Custom packaging design and printing

- Specification modifications (barrel length, plunger color, measurement units)

- Exclusive product development for unique market needs

Compliance & Certification: All animal feeding syringes include product certifications, material safety data sheets (MSDS), and compliance documentation for customs clearance and marketplace listing requirements.

HOW – Product Applications & Usage

Neonatal Bird Feeding: Our precision bird feeding syringe allows controlled formula delivery for:

- Hand-raising parrot chicks from hatchling to weaning

- Supplemental feeding of weak or rejected chicks

- Medication administration with accurate dosing

Multi-Species Compatibility: The bird syringe range accommodates various sizes:

- 1-5ml: Finches, canaries, budgies, lovebirds

- 10-20ml: Cockatiels, conures, small parrots

- 30-60ml: African greys, amazons, cockatoos, macaws

- 100ml: Large macaws, breeding operations, batch preparation

Veterinary Applications: Professional animal feeding syringes support clinical procedures including crop feeding, medication delivery, nutritional supplementation, and post-surgical care.

Operational Efficiency: Designed for repeated daily use with:

- Easy disassembly for thorough cleaning

- Dishwasher-safe components (top rack)

- Autoclavable materials for clinical settings

- Durable construction withstanding hundreds of feeding cycles

HOW MUCH – Wholesale Pricing Structure

Tiered Volume Pricing for standard bird feeding syringe kits:

- 500-999 units: Base wholesale price

- 1,000-4,999 units: 15% discount

- 5,000-9,999 units: 25% discount

- 10,000-29,999 units: 30% discount

- 30,000+ units: 35% discount + custom terms

Custom Product Development: Tooling costs for proprietary bird syringe designs range from $800-$3,000 depending on complexity, amortized across production runs. Minimum order quantities for custom products start at 3,000 units.

Flexible Payment Terms:

- New clients: 30% deposit, 70% before shipment

- Established partners: NET 30-60 terms available

- Large orders: Milestone payment schedules

Sample Policy: First sample set of animal feeding syringes provided at cost plus shipping. Sample fees fully credited against initial wholesale order exceeding $1,000.

Quality Assurance & After-Sales Support

Every bird feeding syringe batch undergoes rigorous testing: dimensional accuracy verification, material composition analysis, pressure resistance testing, and visual inspection. We maintain product liability insurance and offer warranty coverage against manufacturing defects.

B2B Support Services:

- Dedicated account managers for order coordination

- Technical consultation for product selection

- Marketing materials and product photography

- Listing optimization support for e-commerce sellers

- Responsive customer service (24-hour email response time)

Start Your Partnership with Kohope

Request a bird syringe sample kit, discuss custom animal feeding syringes development, or place your first wholesale order today. Contact our B2B sales team for detailed quotations, product specifications, and partnership opportunities.

Grow your business with reliable, high-quality bird feeding solutions from a manufacturer you can trust.