Introduction: Why Syringe Size Selection Matters in Clinical Practice

Selecting the appropriate plastic syringe size isn’t merely about volume capacity—it directly impacts medication accuracy, patient comfort, procedural efficiency, and clinical outcomes. Whether you’re a hospital procurement manager, clinic administrator, or healthcare professional, understanding the relationship between syringe specifications and clinical applications ensures optimal patient care while maximizing cost-efficiency.

This comprehensive guide examines how different irrigation syringe and oral syringe sizes align with specific medical procedures, which configurations offer cross-application versatility, and critical factors that determine interchangeability across clinical settings.

Understanding Medical Syringe Size Classifications

Standard Capacity Categories

Medical plastic syringes are manufactured in standardized volumes to accommodate diverse clinical requirements:

Micro-Volume Syringes (1ml-3ml) These precision instruments serve applications requiring exact dosing where even minor volume variations affect therapeutic outcomes. The 1ml plastic syringe typically features 0.01ml graduation increments, essential for:

- Pediatric medication administration

- Insulin and anticoagulant injections

- Tuberculin skin testing

- Neonatal care applications

- Allergen immunotherapy

The 2ml and 3ml variants bridge micro-dosing precision with slightly larger volume needs, commonly used in vaccination programs and subcutaneous medication delivery.

Small-Volume Syringes (5ml-10ml) The workhorse category for general clinical practice, these plastic syringe sizes handle the majority of routine medical procedures:

- Intramuscular vaccinations (influenza, COVID-19, hepatitis)

- Blood sample collection

- IV medication preparation

- Wound irrigation for minor injuries

- Diagnostic fluid sampling

The 5ml oral syringe represents the most versatile size for pediatric liquid medication administration, balancing adequate capacity with manageable volume for young patients.

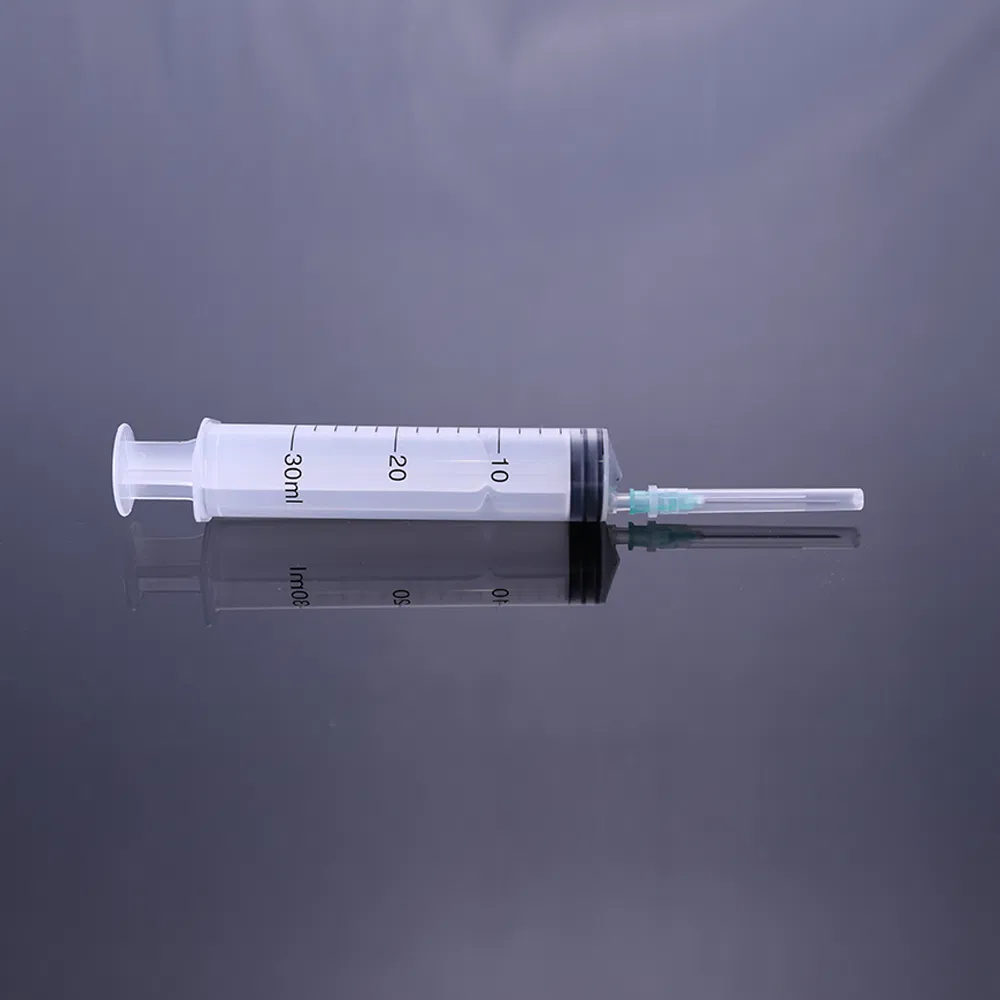

Medium-Volume Syringes (20ml-30ml) Specialized applications requiring substantial fluid delivery rely on these intermediate capacities:

- Irrigation syringes for ear canal cleaning

- Wound debridement and lavage

- Enteral feeding (when gavage tubes are unavailable)

- Contrast media injection for imaging procedures

- Joint aspiration and injection procedures

The 20ml irrigation syringe has become the clinical standard for cerumen removal, offering sufficient pressure generation without excessive force that might damage tympanic membranes.

Large-Volume Syringes (50ml-60ml) High-capacity plastic syringes serve situations demanding substantial volume delivery:

- Large wound irrigation

- Gastric lavage procedures

- Bladder irrigation

- Veterinary applications (large animal medication)

- Industrial medical waste sampling

Application-Specific Syringe Selection Guide

Injection Applications: Matching Needle Gauge to Syringe Size

Subcutaneous Injections Medication administered into subcutaneous tissue typically uses 1ml-3ml plastic syringes paired with 25G-27G needles (0.5-0.6mm diameter). This combination provides:

- Minimal tissue trauma

- Adequate medication delivery speed

- Patient comfort optimization

- Precise dosing for potent medications

Interchangeability Note: While 1ml and 3ml syringes both accommodate subcutaneous delivery, the 1ml variant offers superior precision for insulin and anticoagulants where dosing errors have significant consequences.

Intramuscular Injections Muscle tissue injections require 3ml-5ml plastic syringes with 21G-23G needles, balancing:

- Viscous medication flow (vaccines, suspensions)

- Adequate injection speed

- Appropriate needle length for muscle penetration

- Volume capacity for standard vaccine doses (0.5-2ml)

Cross-Application Potential: A 5ml plastic syringe can serve both intramuscular and intravenous preparation needs, making it highly cost-effective for inventory management.

Intravenous Medication Preparation IV drug preparation commonly employs 5ml-10ml syringes, selected based on:

- Medication concentration and required dilution

- IV line compatibility (Luer Lock vs. Luer Slip)

- Drawing efficiency from medication vials

- Waste minimization for expensive pharmaceuticals

Irrigation Applications: Pressure and Volume Considerations

Ear Irrigation Syringes Cerumen removal demands specific irrigation syringe characteristics:

Optimal Size: 20ml capacity Rationale: Generates adequate pressure (approximately 50-100 mmHg) for effective cerumen dislodgement without exceeding safe thresholds that could perforate tympanic membranes.

Alternative Sizes: 30ml irrigation syringes provide extended irrigation duration, reducing refill frequency during difficult impaction cases. However, larger plunger diameters may generate excessive pressure if not carefully controlled.

Interchangeability Assessment: 10ml syringes lack sufficient volume for efficient irrigation, requiring frequent refills. 50ml+ syringes risk excessive pressure generation. The 20-30ml range represents the safety-effectiveness sweet spot.

Eye Irrigation Syringes Ocular surface irrigation for chemical exposure or foreign body removal requires gentle, controlled fluid delivery:

Optimal Size: 10ml-20ml plastic syringe Rationale: Provides adequate volume for continuous irrigation while allowing precise pressure control to prevent corneal damage.

Special Considerations: Eye irrigation often uses oral syringes (without needles) to eliminate accidental needle-stick risks. The smooth tip allows safe periocular placement.

Cross-Application: Standard 10ml plastic syringes with needles removed serve dual purposes for both injection preparation and emergency eye irrigation, enhancing inventory versatility.

Wound Irrigation Syringes Wound debridement effectiveness depends on irrigation pressure (4-15 psi optimal range):

Small Wounds (<5cm): 10ml-20ml irrigation syringe with 18G-19G catheter tip provides targeted high-pressure irrigation

Medium Wounds (5-15cm): 30ml capacity offers extended irrigation without frequent refills

Large Wounds/Burns (>15cm): 50ml-60ml plastic syringes enable efficient coverage of extensive tissue areas

Universal Application Potential: A 30ml irrigation syringe effectively handles 80% of wound irrigation scenarios, making it a strategic inventory choice for emergency departments.

Oral Medication Administration: Needle-Free Safety Design

Pediatric Oral Syringes Children’s liquid medication delivery prioritizes safety and accuracy:

Infant Doses (<1 year): 1ml-3ml oral syringe with 0.1ml graduations

- Prevents overdosing with small therapeutic windows

- Reduces choking risk through controlled delivery

- Compatible with most pediatric medication suspensions

Toddler Doses (1-5 years): 5ml oral syringe standard

- Accommodates common antibiotic suspension volumes (2.5-5ml)

- Easy-grip barrel for parent administration

- Clear graduations for caregiver verification

Child Doses (6-12 years): 10ml capacity extends range for larger doses without intimidating size

Interchangeability Analysis: While a 10ml oral syringe technically administers smaller volumes, the 5ml size offers psychological advantages for young children (less intimidating) and reduces medication waste adherence to barrel walls.

Geriatric Oral Syringes Elderly patients with dysphagia or hand tremors benefit from specific oral syringe characteristics:

Recommended Size: 10ml-20ml with ergonomic plunger

- Accommodates crushed medication suspensions

- Larger barrel easier to grip with arthritic hands

- Graduations sized for visual impairment

Enteral Feeding Applications When standard feeding tubes unavailable, oral syringes provide temporary enteral nutrition:

Minimum Size: 30ml-60ml for practical feeding efficiency Special Feature: Catheter-tip design (not Luer Lock) prevents accidental IV connection—a critical safety feature

Important: These large oral syringes are NOT interchangeable with injection syringes due to different tip designs preventing IV misconnection.

Interchangeability Matrix: When Syringes Can Serve Multiple Purposes

High Interchangeability Scenarios

5ml Plastic Syringe—The Universal Workhorse This capacity demonstrates maximum versatility across applications:

✓ Intramuscular injections (primary use) ✓ Subcutaneous injections (when 1ml unavailable) ✓ IV medication preparation ✓ Small wound irrigation (without needle) ✓ Oral medication (needle removed, urgent situations) ✓ Blood sample collection ✓ Veterinary small animal use

Procurement Advantage: A 5ml plastic syringe inventory serves 70% of general clinical needs, optimizing stock efficiency.

10ml Plastic Syringe—Secondary Versatility ✓ IV flush preparation ✓ Medium-volume oral medications ✓ Small-scale irrigation ✓ Diagnostic sampling ✓ Contrast media preparation

20ml Irrigation Syringe—Dual Purpose ✓ Ear irrigation (primary) ✓ Eye irrigation (needle removed) ✓ Wound irrigation (small-medium) ✓ Oral medication (large pediatric doses)

Limited Interchangeability Scenarios

1ml Precision Syringes These specialized instruments have restricted cross-application due to:

- Critical accuracy requirements (insulin, anticoagulants)

- Incompatible with larger volume needs

- Specific graduated markings (0.01ml increments)

Alternative Use: Tuberculin testing only—medication dosing should NOT substitute with larger syringes due to accuracy loss.

60ml Large-Volume Syringes Physical size limitations prevent versatile application:

- Too large for standard injections

- Excessive pressure risk for delicate irrigation

- Impractical for medication preparation

Dedicated Use: Large wound irrigation, bladder irrigation, veterinary applications exclusively.

Zero Interchangeability: Safety-Critical Distinctions

Oral Syringes vs. Injection Syringes NEVER interchangeable due to:

- Tip Design Differences: Oral syringes use catheter tips (wider, blunt) preventing IV connection; injection syringes use Luer Lock/Slip enabling needle attachment

- Safety Standards: Oral syringes specifically engineered to prevent accidental IV administration—a “Never Event” in patient safety protocols

- Regulatory Compliance: Healthcare facilities face severe penalties for using injection syringes for oral medication due to documented fatal errors

Critical Safety Principle: Even in resource-limited situations, injection plastic syringes must NEVER substitute for oral syringes in medication administration. The needle-removal workaround doesn’t address Luer connection IV misconnection risks.

Material Considerations Affecting Application Suitability

Polypropylene (PP) Barrel Construction

Medical-grade PP offers broad chemical compatibility, making plastic syringes suitable for:

✓ Aqueous medications ✓ Alcohol-based solutions (up to 70%) ✓ Most antibiotics and vaccines ✓ Saline and sterile water

Limitation: Some chemotherapy agents and certain lipid-based medications may require glass syringes due to PP interaction potential.

Natural Rubber Plungers vs. Synthetic Alternatives

Traditional plastic syringe plungers use natural rubber, creating considerations:

Latex Allergy Concerns: Patients with documented latex sensitivity require latex-free synthetic rubber plungers

Medication Compatibility: Nitroglycerin and certain hormones adsorb to natural rubber, requiring silicone-coated or synthetic plungers

Interchangeability Impact: Standard irrigation syringes with natural rubber pose no latex exposure risk (no bloodstream contact), but injectable medications require latex-free verification.

Luer Lock vs. Luer Slip: Connection Type Selection

Luer Lock Advantages

The threaded connection system provides:

- Secure needle attachment preventing disconnection during injection

- Essential for high-pressure applications (power injection, arterial lines)

- Required for certain irrigation procedures (joint aspiration)

Best Applications:

- Intramuscular injections with viscous medications

- IV push medications

- Any procedure where needle dislodgement creates safety risks

Luer Slip Benefits

The friction-fit connection offers:

- Faster needle attachment/removal

- Adequate for low-pressure applications

- Cost-effective manufacturing (slightly lower pricing)

Best Applications:

- Subcutaneous injections (low pressure)

- Single-use quick procedures

- Situations requiring rapid syringe exchanges

Cross-Compatibility

Important: Luer Lock syringes accept both Luer Lock and Luer Slip needles, but Luer Slip syringes ONLY accommodate Luer Slip needles.

Procurement Strategy: Stocking Luer Lock plastic syringes provides maximum flexibility, though costs approximately 5-8% more than Luer Slip equivalents.

Veterinary Applications: Size Selection for Animal Species

Small Animal Practice (Cats, Dogs, Small Mammals)

Subcutaneous Fluids: 20ml-30ml irrigation syringes enable efficient fluid administration for dehydrated pets

Vaccinations: 3ml-5ml plastic syringes mirror human vaccine administration

Oral Medications: 10ml-20ml oral syringes handle common liquid antibiotic volumes for medium dogs

Interchangeability with Human Medical: Veterinary clinics often utilize identical plastic syringe specifications as human healthcare, creating procurement efficiencies through dual-purpose inventory.

Large Animal Practice (Horses, Cattle, Livestock)

Intramuscular Injections: 30ml-60ml syringes accommodate large medication volumes (antibiotics, vaccines)

Oral Drenching: 60ml oral syringes deliver dewormers and oral medications

Wound Care: 50ml+ irrigation syringes efficiently clean large animal injuries

Species-Specific Considerations: Equine medicine may require specialized dose syringes beyond standard 60ml capacity—typically 100ml+ configurations.

Specialized Syringe Variations and Their Applications

Catheter-Tip Syringes

Modified oral syringe design featuring:

- Tapered, blunt tip (no Luer connection)

- Gastric tube compatibility

- Tracheostomy care applications

- Wound irrigation with catheter attachment

Cross-Application Potential: Limited—catheter-tip design prevents needle attachment, restricting use to irrigation and enteral delivery exclusively.

Eccentric-Tip Syringes

Off-center nozzle placement enables:

- Parallel needle positioning to skin (reduces injection angle discomfort)

- IV line connections in confined spaces

- Specialized veterinary procedures

Interchangeability: These specialized plastic syringes serve niche applications but lack the versatility of concentric-tip standard designs.

Tuberculin Syringes

The 1ml plastic syringe with integrated 25G-27G needle specifically engineered for:

- Tuberculin skin testing (PPD)

- Allergy testing

- Pediatric vaccines requiring <0.5ml volumes

Non-Interchangeable: Permanent needle attachment prevents alternative applications—strictly dedicated to intradermal and select subcutaneous injections.

Needle Gauge Compatibility Across Syringe Sizes

Understanding Gauge-Size Relationships

Smaller syringes typically pair with higher-gauge (thinner) needles, but compatibility extends beyond conventional pairings:

1ml Syringe: 25G-30G standard, but accepts 23G for viscous medications 3ml Syringe: 21G-25G typical range 5ml-10ml Syringe: 18G-23G accommodates most medications 20ml+ Irrigation Syringe: 14G-19G for irrigation catheters or can be used without needles

Interchangeability Principle: Luer connections standardize across sizes, meaning a 1ml plastic syringe physically accepts an 18G needle, though clinical scenarios rarely require this combination.

Practical Limitation: Very large needles (14G-16G) create excessive dead space in small syringes, wasting expensive medications and compromising dose accuracy.

Procurement Strategy: Optimizing Inventory Through Smart Interchangeability

Essential Stock Levels by Clinical Setting

General Practice Clinic

- 3ml plastic syringe (30% of inventory): Vaccines, IM injections

- 5ml plastic syringe (40% of inventory): Universal workhorse

- 10ml oral syringe (20% of inventory): Pediatric medications

- 20ml irrigation syringe (10% of inventory): Ear cleaning, wound care

Emergency Department

- 5ml plastic syringe (25%): IV medication preparation

- 10ml plastic syringe (25%): IV flushes, sampling

- 20ml irrigation syringe (15%): Eye/wound irrigation

- 30ml-60ml irrigation syringe (10%): Large wound lavage

- Various oral syringes (10%): Activated charcoal, oral meds

Pediatric Facility

- 1ml plastic syringe (15%): Infant vaccines, precise dosing

- 3ml plastic syringe (20%): Toddler vaccines

- 5ml oral syringe (30%): Standard liquid medication

- 10ml oral syringe (20%): Larger pediatric doses

- 20ml irrigation syringe (5%): Ear irrigation

Cost-Efficiency Through Versatility

High-Value Versatile Items:

- 5ml Luer Lock plastic syringe: Single SKU serves 6+ applications

- 20ml irrigation syringe: Dual-purpose (ear/wound) reduces specialized inventory

- 10ml oral syringe: Pediatric-geriatric crossover utility

Specialized Low-Turnover Items:

- 1ml tuberculin syringes (purchase smaller quantities)

- 60ml large-volume syringes (emergency stock only)

- Eccentric-tip variants (order as-needed)

Bulk Purchasing Recommendation: Focus 70% of procurement budget on the 3ml-10ml range, maximizing volume discounts while maintaining clinical flexibility.

Safety Protocols: Preventing Cross-Application Errors

Color-Coding Systems

Visual differentiation prevents dangerous substitutions:

Injection Syringes: Clear/transparent barrels with standard graduations Oral Syringes: Amber or purple-tinted barrels with “ORAL USE ONLY” imprinting Irrigation Syringes: Blue-tinted for immediate visual identification

Critical Safety Measure: Never remove color-coding labels or markings that distinguish oral syringes from injection variants.

Storage Separation

Physical segregation reduces selection errors:

- Dedicated oral medication preparation areas

- Separate injection preparation spaces

- Clearly labeled irrigation supply sections

Best Practice: Store oral syringes in different cabinets from plastic syringes intended for injection, even if both are needle-free.

Training and Protocols

Healthcare staff education must emphasize:

- Never Events: Using injection syringes for oral medication

- Appropriate Substitutions: When 5ml can replace 3ml safely

- Prohibited Substitutions: Injection for oral, vice versa

- Size-Specific Applications: Why 1ml precision matters for certain drugs

Quality Considerations Affecting Multi-Purpose Use

Sterilization and Shelf Life

EO gas-sterilized plastic syringes maintain 5-year sterility when packaged properly, but storage conditions affect interchangeability:

Proper Storage: Climate-controlled environment preserves lubricant coating essential for smooth plunger operation across all applications

Degraded Storage: Extreme temperatures may compromise rubber integrity, restricting use to low-pressure applications (oral delivery) while rendering high-pressure uses (irrigation) unsafe

Graduation Accuracy Standards

ISO-certified plastic syringes meet different accuracy tolerances by size:

- 1ml syringe: ±4% tolerance (critical for insulin)

- 5ml-10ml syringe: ±5% tolerance (adequate for most medications)

- 20ml+ syringe: ±5% tolerance (acceptable for irrigation)

Interchangeability Impact: Using 10ml syringe for 0.3ml dose introduces unacceptable error margins versus 1ml syringe—size-appropriate selection maintains clinical safety.

International Standards and Regional Variations

ISO 7886 Compliance

This international standard governs plastic syringe specifications:

- Dimensional tolerances

- Graduation marking requirements

- Barrel transparency standards

- Plunger force specifications

Global Interchangeability: ISO-compliant syringes from different manufacturers maintain functional equivalence for identical size categories.

Regional Regulatory Differences

US FDA Requirements: More stringent traceability for injectable plastic syringes versus oral syringes

EU CE Marking: Class IIa medical device classification for injection syringes; Class I for irrigation variants

Procurement Impact: Regional certification affects which products qualify for specific applications—verify certification alignment with intended use during sourcing.

Future Trends: Smart Syringes and Application Specialization

Safety-Engineered Syringes

Retractable needle plastic syringes represent growing adoption:

Advantages: Prevent needlestick injuries post-injection Limitation: Single-purpose design—cannot be repurposed for irrigation or oral use Cost Impact: 40-60% premium over standard syringes

Interchangeability Reduction: Safety features increasingly create application-specific products, reducing the versatility that characterizes traditional plastic syringes.

Pre-Filled Syringe Systems

Manufacturer-supplied medication in ready-to-administer plastic syringes:

Benefits: Eliminate preparation errors, reduce contamination Limitation: Zero interchangeability—single medication/dose only Emerging Applications: Vaccines, emergency medications (epinephrine, naloxone)

RFID-Enabled Inventory Management

Smart irrigation syringes and oral syringes with embedded RFID:

Functionality: Track expiration, usage patterns, compliance Future Potential: Automated alerts preventing inappropriate cross-application use

Case Studies: Interchangeability in Practice

Case Study 1: Rural Clinic Inventory Optimization

Challenge: Limited budget requiring minimal SKU count while maintaining comprehensive care capabilities

Solution Strategy:

- Core inventory: 3ml, 5ml, 10ml plastic syringes (Luer Lock)

- Secondary stock: 10ml, 20ml oral syringes

- Emergency reserve: 30ml irrigation syringes

Outcome: 6 SKU types covered 95% of clinical needs through strategic interchangeability, reducing inventory costs 40% versus comprehensive stocking approach.

Case Study 2: Pediatric Hospital Safety Initiative

Challenge: NICU near-miss event where injection syringe nearly used for oral medication

Solution Implementation:

- Complete separation of oral syringe inventory (dedicated cabinet with key access)

- Color-coded procurement (all oral = purple tint)

- Zero tolerance policy for injection-to-oral substitution

Outcome: Zero oral medication errors in 24-month follow-up period; staff satisfaction increased due to clear protocols.

Case Study 3: Veterinary Practice Cross-Application Efficiency

Challenge: Small animal practice with limited storage needing human and veterinary applications

Solution Strategy:

- Sourced ISO 13485-certified plastic syringes approved for both human and veterinary use

- Emphasized 10ml and 20ml sizes serving dual purposes (pet medications, owner education samples)

Outcome: Single inventory served both client bases; regulatory compliance maintained through appropriate certifications.

Practical Decision-Making Framework

When to Prioritize Application-Specific Syringes

Choose dedicated oral syringes or irrigation syringes when:

✓ High patient volume in specific application category ✓ Safety-critical environment (pediatrics, geriatrics) ✓ Regulatory requirements mandate specialized equipment ✓ Staff training levels vary significantly

When to Leverage Interchangeable Syringes

Rely on versatile plastic syringes when:

✓ Budget constraints limit SKU proliferation ✓ Storage space is restricted ✓ Clinical volume doesn’t justify specialized inventory ✓ Emergency preparedness requires multi-purpose supplies

Questions to Guide Selection

- What is the primary application? (determines baseline size)

- What secondary uses might arise? (assesses versatility value)

- Are there safety regulations preventing cross-application? (oral vs. injection)

- What is the patient population? (pediatric needs differ from adult/geriatric)

- What are the cost-benefit trade-offs? (specialized vs. versatile inventory)

Conclusion: Strategic Syringe Selection for Optimal Clinical Care

Understanding the nuanced relationships between plastic syringe sizes, irrigation syringe applications, and oral syringe safety considerations empowers healthcare facilities to make informed procurement decisions balancing clinical efficacy, patient safety, and cost management.

Key Takeaways:

Versatility Champions: 5ml and 10ml plastic syringes offer maximum interchangeability across injection, preparation, and some irrigation applications—prioritize these sizes for general inventory.

Safety-Critical Distinctions: Oral and injection syringes are NEVER interchangeable regardless of size—maintain strict separation protocols to prevent potentially fatal medication errors.

Application-Specific Optimization: While 20ml irrigation syringes primarily serve ear cleaning, their design accommodates eye and wound irrigation, making them strategic secondary-purpose investments.

Size Matters for Precision: Insulin, anticoagulants, and pediatric medications demand size-appropriate syringes (1ml-3ml)—cost savings from using larger syringes create unacceptable clinical risks.

Procurement Intelligence: Focus bulk purchasing on the 3ml-10ml range while maintaining strategic specialized inventory (1ml precision, 60ml large-volume) for specific clinical scenarios.

By aligning plastic syringe, irrigation syringe, and oral syringe selection with evidence-based application requirements while leveraging appropriate interchangeability, healthcare organizations optimize both patient outcomes and operational efficiency.

Related Resources:

- ISO 7886 Standards for Medical Syringes

- Safe Medication Administration Protocols

- Healthcare Inventory Management Best Practices

- Wholesale Medical Syringe Procurement Guide

Keywords: plastic syringe, irrigation syringes, oral syringe, medical syringe sizes, luer lock syringe, disposable syringe, syringe interchangeability, ear irrigation syringe, injection syringe, veterinary syringe