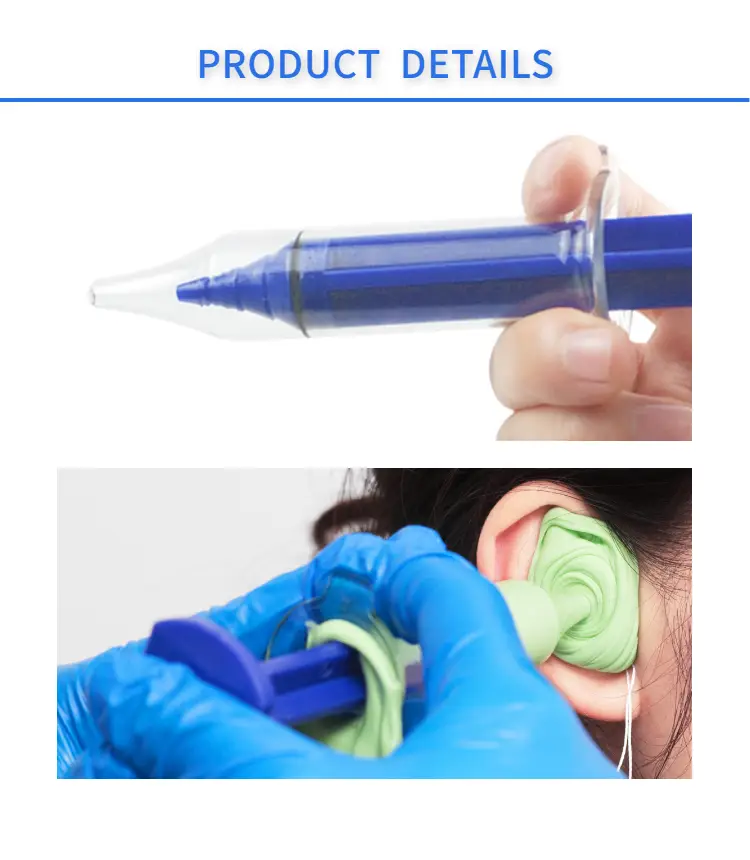

In the medical device industry, custom syringes have become a crucial tool for enhancing brand image and product professionalism. Today, we’re excited to share a successful customization case study featuring earmold impression syringes, demonstrating how custom printed syringes helped our client stand out in the competitive hearing healthcare market.

Client Background & Requirements

Our client is a professional supplier specializing in hearing healthcare equipment, primarily serving hearing aid fitting centers and audiology clinics. During the ear mold manufacturing process, earmold impression syringes are essential professional tools. The client sought custom syringes to achieve several key objectives:

- Strengthen brand recognition in a crowded marketplace

- Elevate product professional image among healthcare providers

- Build trust with end-users and practitioners

- Differentiate from generic market alternatives

Customization Solution Design

Product Selection

For the specialized application of earmold impressions, we recommended professional-grade earmold impression syringes. These custom syringes needed to feature:

- Precise volume graduations for accurate measurements

- Smooth plunger operation for consistent material delivery

- Appropriate barrel diameter suitable for silicone impression materials

- Medical-grade materials meeting industry standards

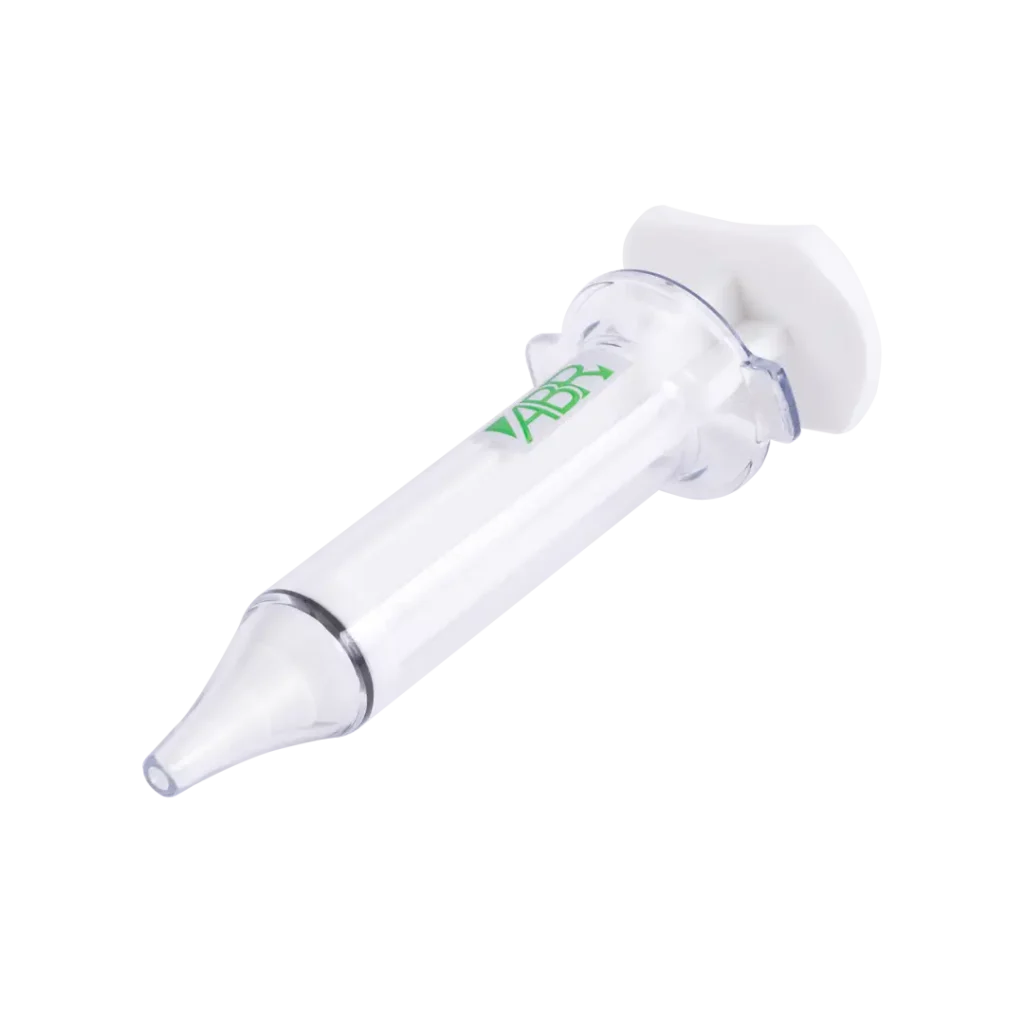

Custom Printing Strategy

As a comprehensive custom printed syringes project, we designed a complete visual branding solution for our client:

- Brand Identity Integration: Client’s logo prominently printed on syringe barrel

- Product Information Labeling: Clear specification markings and usage instructions

- Color Coordination: Printing colors aligned with client’s brand identity

- Anti-Counterfeiting Features: Special security elements for product authentication

The custom printed syringes design ensured maximum brand visibility while maintaining professional medical aesthetics.

Custom Packaging Solution

Beyond the custom syringes themselves, we provided coordinated custom packaging. The packaging featured detailed product information, usage guidelines, and brand elements, ensuring complete brand consistency from product to presentation.

Production Process Excellence

Sample Approval Phase

Before full-scale production of the earmold impression syringes, we provided sample units for comprehensive client evaluation. The client thoroughly assessed printing quality, color accuracy, and product functionality, ensuring the final custom printed syringes would meet all expectations.

Volume Manufacturing

Following sample approval, we initiated our streamlined production process:

- Raw material inspection to ensure quality standards

- Precision injection molding for consistent dimensions

- High-quality printing with medical-grade inks

- Rigorous quality control at every production stage

- Sterile packaging meeting medical device requirements

Every earmold impression syringe underwent strict quality assurance protocols, guaranteeing professional-grade performance.

Project Results & Impact

Client Testimonial

Our client expressed exceptional satisfaction with these custom printed syringes, reporting significant positive outcomes:

- Enhanced Brand Recognition: Audiology clinics and fitting centers developed stronger brand awareness through these distinctive custom syringes

- Elevated Professional Image: The earmold impression syringes positioned the client as a premium, professional supplier

- Increased Customer Loyalty: After adopting custom printed syringes, repeat purchase rates improved substantially

- Competitive Market Advantage: Product differentiation through custom syringes attracted numerous new customers

Market Performance

These earmold impression syringes received widespread acclaim from hearing healthcare professionals. Many audiologists noted that using branded professional custom syringes not only improved workflow efficiency but also enhanced patient confidence in service quality.

The Value of Customization

This case study clearly demonstrates the significant value custom printed syringes bring to professional medical applications:

- Brand Building: Every product use becomes a brand exposure opportunity

- Quality Assurance: Custom syringes enable superior quality control

- Professional Recognition: Demonstrates attention to detail and quality commitment

- Market Differentiation: Creates unique advantages in commoditized markets

The investment in earmold impression syringes customization delivered measurable ROI through enhanced market positioning.

Conclusion

This earmold impression syringe customization project successfully showcases the practical application value of custom printed syringes in the professional medical device sector. Whether for functional requirements or brand presentation, custom syringes deliver tangible business value.

Are you seeking professional custom syringe solutions? If you’re looking to elevate your brand image through customized products, we offer extensive experience and professional expertise in delivering comprehensive services from design through production for earmold impression syringes and other custom printed syringes.