In the medical device and industrial application sectors, standardized products often fall short of meeting specialized requirements. This is why an increasing number of businesses are turning to custom syringes solutions. This article explores the customer intent behind custom syringe demand and provides a professional guide to choosing the right customization services.

Medical Professional Applications: Precision Defines Professionalism

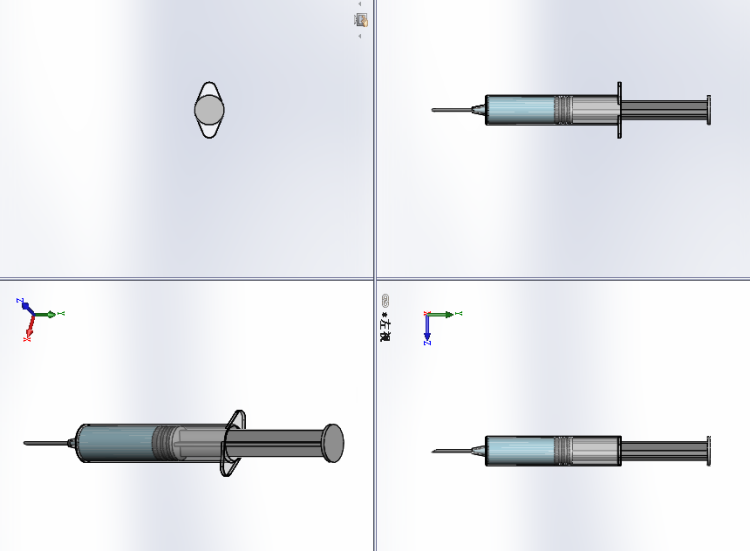

In certain medical fields, generic syringes simply cannot handle specialized tasks. Take the audiology industry as an example—the earmold impression syringe represents a quintessential case of customization necessity. Audiologists require precise delivery of impression material into patients’ ear canals to create personalized hearing aid molds. This application demands specific nozzle designs, accurate volume control, and ergonomically optimized grip angles.

Standard syringes cannot provide this level of precision. Custom made syringes can be tailored to clinical practice requirements by adjusting barrel diameter, plunger stroke, and material hardness, ensuring optimal results for every impression procedure. These specialized tools not only boost workflow efficiency but, more importantly, enhance patient experience.

Understanding Customization Tiers: Matching Solutions to Your Needs

Understanding the service levels of custom syringes is crucial, as different customization depths directly impact minimum order quantities (MOQs), lead times, and cost investments.

1. Logo Printing Customization (Entry-Level)

MOQ: 1,000-5,000 units

This is the most common and flexible customization method. Through silk screen or pad printing techniques, company logos, product names, or usage instructions are added to standard syringes. Custom printed syringes are ideal for clients who need brand visibility without altering product structure.

Ideal Applications:

- Medical facilities establishing brand recognition

- Vaccination program identification

- Promotional campaign exclusive packaging

- Product serial numbers or batch traceability

The advantage of printing customization lies in relatively low MOQs, short delivery cycles (typically 2-4 weeks), and no mold costs. Clients can choose single-color, two-color, or even full-color printing, adjusting flexibly according to budget.

2. Packaging Customization (Mid-Level)

MOQ: 10,000-50,000 units

Packaging customization involves personalized design of outer boxes, blister packaging, sterile bags, and more. This tier doesn’t alter the syringe itself but elevates product quality and user experience through professional packaging.

Customizable Elements Include:

- Package box dimensions and material selection

- Print design (product information, usage diagrams, multilingual instructions)

- Sterile packaging grades (EO sterilization, gamma radiation sterilization)

- Anti-counterfeiting labels and traceability codes

Packaging customization is particularly suitable for export businesses, as different countries have varying requirements for medical device packaging labels. Through customized packaging, companies can ensure compliance with target market regulations while reinforcing brand image. Higher MOQs are necessary because packaging materials and printing typically have minimum production batch limitations.

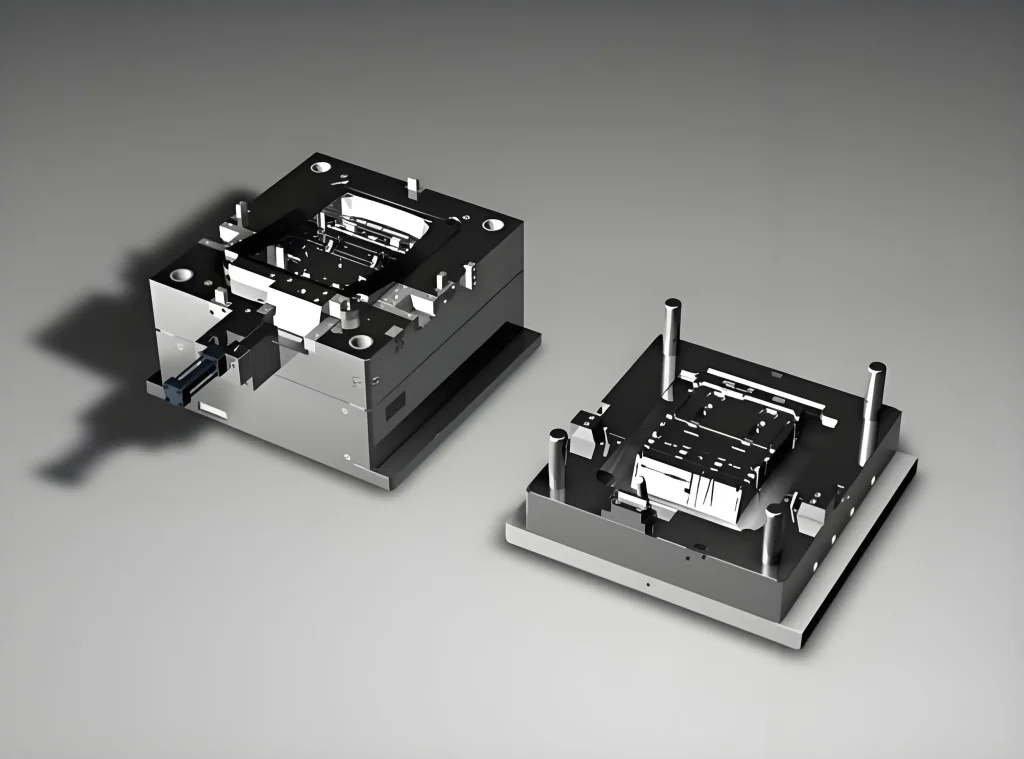

3. Shape Mold Customization (Advanced-Level)

MOQ: 50,000-100,000 units minimum

This is the deepest level of customization service, involving syringe structural design and mold development. Custom made syringes at this tier can achieve completely unique functionality and appearance.

Adjustable Elements in Mold Customization:

- Barrel shape (round, oval, special cross-sections)

- Volume specifications (non-standard capacities like 7ml, 15ml)

- Nozzle design (special angles, multi-port, extended types)

- Plunger structure (precision graduations, anti-drawback design)

- Ergonomic handle design

- Special functional components (safety locks, dose limiters)

Cost Breakdown:

- Mold development fee: $3,000-$15,000 (depending on complexity)

- Sample production and testing

- Higher unit price for initial production runs

The high MOQ for shape mold customization is determined by mold cost amortization. For instance, if a mold costs $10,000 spread across 50,000 units, each unit adds $0.20; but spread across 100,000 units, each only adds $0.10. For businesses with long-term demand, this is the most cost-effective solution.

Typical Application Cases:

- Earmold impression syringes requiring specialized curved nozzles and precise extrusion control

- Veterinary vaccine syringes needing larger capacity and reinforced structure

- Industrial dispensing syringes requiring chemically resistant special materials

- Dental impression syringes needing specific mixing ratio designs

How to Choose the Right Customization Tier

When selecting customization services, businesses should consider the following factors:

Annual Usage Volume Assessment:

- Below 10,000 units: Recommend printing customization

- 10,000-50,000 units: Consider packaging customization

- Over 50,000 units: Shape mold customization offers economic value

Product Life Cycle: Short-term projects suit printing customization, while long-term product lines justify mold investment. If products require continuous use for 3-5 years, mold costs can be effectively amortized across multiple order batches.

Functional Requirement Urgency: If standard products completely fail to meet functional needs (such as specialized applications like earmold impression syringes), shape mold customization is the only option. If you only need brand recognition or market differentiation, printing or packaging customization suffices.

Budget and Cash Flow: Printing customization requires the lowest initial investment, suitable for budget-limited or first-time customization businesses. Mold customization demands larger upfront investment but offers better long-term unit pricing.

Industrial Applications: Professional Solutions for Special Scenarios

The demand for custom syringes extends beyond medical fields. In electronics manufacturing, precision instrument maintenance, laboratory research, and other industrial scenarios, custom syringes solve challenges that standard products cannot address.

Electronic component dispensing requires extremely precise small-dosage control, typically necessitating shape mold customization for micro syringes. Chemical experiments may require corrosion-resistant special materials, demanding material customization. Food industries need FDA-compliant food-grade syringes, involving a combination of material certification and packaging customization.

Brand Value: Customization Equals Differentiation

Custom printed syringes transform each syringe into a brand touchpoint. Printing company logos, product information, or usage instructions on packaging helps healthcare professionals quickly identify medication types, reducing medication error risks.

For vaccination programs or specialized medical projects, custom printed syringes enhance patient trust in the program. When patients see professionally designed medical devices, they perceive higher levels of healthcare service quality. Even the most basic printing customization can deliver significant brand premium value.

Compliance and Quality Assurance

Regardless of which customization tier you choose, custom made syringes must meet stringent quality standards. Professional suppliers should provide:

- ISO 13485 medical device quality management system certification

- FDA registration or CE certification

- Biocompatibility test reports

- Sterile packaging validation documentation

- Complete material traceability records

Shape mold customization typically requires longer certification cycles (3-6 months) because new designs need comprehensive performance validation. Printing and packaging customization certifications are relatively simpler, as base products already have certification—only confirming that printing materials and packaging materials meet requirements is necessary.

Conclusion: Precision Matching from Needs to Solutions

From entry-level custom printed syringes to advanced shape mold custom made syringes, and specialized earmold impression syringes, the diversity of custom syringe services provides flexible options for businesses of different scales and needs.

Understanding the MOQ differences and cost structures of different customization tiers enables smarter decision-making. Small-batch requirements don’t necessitate mold development, while large-volume procurement should fully leverage customization advantages to reduce long-term costs. Choosing the right custom syringes supplier that matches your business stage and development plan is where the true value of customization lies.

On the path toward professionalism, the right customization strategy not only solves functional problems but also creates brand value and cost advantages.

Key Takeaways:

- Custom syringes offer three main tiers: printing, packaging, and mold customization

- MOQs range from 1,000 units for custom printed syringes to 50,000+ for mold development

- Earmold impression syringes exemplify specialized medical applications requiring custom made syringes

- Match customization tier to your annual volume, product lifecycle, and budget constraints