In today’s veterinary medicine landscape, few tools are as fundamental and versatile as the veterinary injection syringe. From routine vaccinations to emergency treatments, veterinary syringes serve as the primary interface between life-saving medications and our animal patients. This essential veterinary medical equipment has evolved significantly over recent decades, adapting to meet the unique challenges of animal healthcare while maintaining the precision and reliability that veterinary professionals depend on every day. Modern veterinary injection syringes represent sophisticated animal healthcare tools designed specifically for the diverse needs of veterinary practice.

The Foundation of Veterinary Care

Veterinary injection syringes represent far more than simple medical devices—they’re the cornerstone of preventive care, therapeutic intervention, and diagnostic procedures across all animal species. Unlike human medical applications, veterinary syringes must accommodate an extraordinary range of patient sizes, from tiny birds weighing just a few grams to massive livestock injection systems for animals weighing several tons. This diversity demands specialized design considerations that set veterinary injection syringes apart from their human medical counterparts.

The importance of these animal healthcare tools extends beyond their mechanical function. They represent a veterinarian’s ability to deliver precise doses of medications, vaccines, and treatments that can mean the difference between life and death for animal patients. In emergency situations, the reliability and ease of use of veterinary syringes can be critical factors in successful patient outcomes.

Understanding Veterinary Syringe Design

Core Components and Engineering

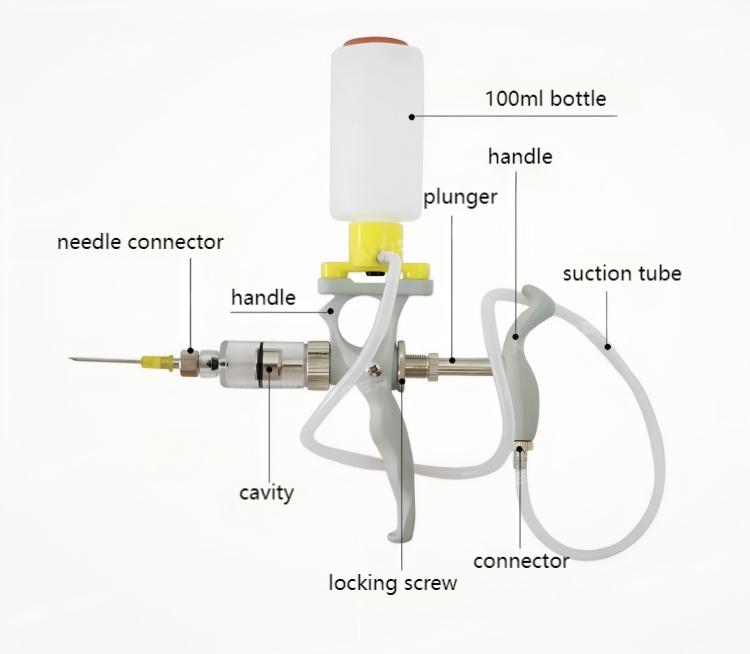

Modern veterinary injection syringes consist of several precisely engineered components working in perfect harmony. The barrel, typically made from medical-grade plastic or glass, provides the main chamber for medication storage and measurement. Clear graduation marks ensure accurate dosing, while the plunger system creates the necessary pressure differential for medication delivery.

The needle attachment system represents a critical interface point. Veterinary syringes often feature Luer-lock or slip-tip connections, with Luer-lock systems providing enhanced veterinary needle safety for challenging applications involving large or aggressive animals. The threading mechanism prevents accidental needle detachment during procedures, which is particularly important when working with powerful livestock injection systems or exotic species.

Material Science and Safety

Contemporary veterinary injection syringes utilize advanced polymer technologies that offer superior chemical resistance, dimensional stability, and biocompatibility. These materials must withstand sterilization processes, resist chemical degradation from various medications, and maintain their integrity across the wide temperature ranges encountered in field veterinary practice.

Veterinary needle safety features have become increasingly sophisticated, incorporating mechanisms to prevent needle-stick injuries—a significant occupational hazard in veterinary medicine. Retractable needle systems, safety caps, and color-coded components help reduce risks to veterinary staff while maintaining the precision required for effective animal healthcare treatment.

Classification and Specialized Applications

Volume-Based Categories

Veterinary syringes span an impressive range of volumes, each optimized for specific applications:

Precision Syringes (0.3-1ml): Essential for small animal medicine, exotic pet care, and precise medication dosing. These ultra-precise animal healthcare tools enable accurate delivery of potent medications where dosing errors could prove fatal.

Standard Syringes (3-20ml): The workhorse of veterinary practice, suitable for most routine vaccinations, antibiotic administrations, and diagnostic sample collection across companion animals and medium-sized livestock injection systems.

Large Volume Syringes (30-60ml): Designed for large animal medicine, these robust veterinary injection syringes handle substantial medication volumes required for cattle, horses, and other large species. Their construction must withstand the physical demands of large animal handling.

Specialized Dose Syringes (100ml+): Used primarily in production animal healthcare for mass vaccination programs and large-volume therapeutic interventions. This veterinary medical equipment often features ergonomic enhancements to reduce operator fatigue during extended use.

Species-Specific Adaptations

Different animal species present unique challenges that influence veterinary syringe selection and design. Equine medicine requires veterinary injection syringes capable of delivering large volumes through thick skin and dense muscle tissue. Avian medicine demands ultra-fine precision for tiny patients where traditional veterinary syringes would be inappropriate. Aquatic veterinary medicine has led to specialized waterproof syringe designs for fish and marine mammal treatment.

Needle Compatibility and Selection

The relationship between syringe and needle selection represents a critical aspect of veterinary injection technique. Needle gauge, length, and tip design must match both the medication characteristics and the anatomical requirements of the target species. Thick-skinned animals like elephants or rhinoceros require robust needles that can penetrate tough hide, while delicate species like birds need ultra-fine needles to minimize tissue trauma.

Clinical Applications Across Veterinary Medicine

Preventive Care and Vaccination Programs

Vaccination represents perhaps the most widespread application of veterinary syringes. From puppy and kitten series to large-scale livestock injection systems immunization programs, veterinary injection syringes enable the delivery of life-saving vaccines that prevent devastating diseases. The precision of dose delivery directly impacts vaccine efficacy, making veterinary syringe accuracy a critical factor in successful immunization programs.

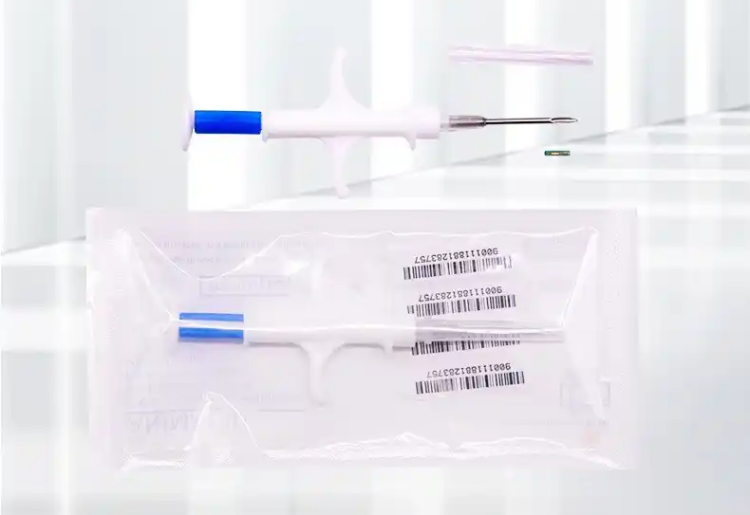

Modern vaccination protocols often require multiple medications administered simultaneously or in rapid succession. This has led to the development of multi-dose syringe systems and automated injection devices that maintain veterinary needle safety while improving efficiency in high-volume vaccination scenarios.

Therapeutic Interventions

Beyond vaccination, veterinary injection syringes serve as the primary delivery method for antibiotics, anti-inflammatory medications, analgesics, and emergency drugs. The route of administration—intramuscular, subcutaneous, intravenous, or intraperitoneal—influences veterinary syringe and needle selection, with each route requiring specific techniques and equipment considerations.

Emergency medicine applications place extreme demands on veterinary medical equipment performance. Rapid drug delivery in crisis situations requires veterinary syringes that function reliably under pressure, often in less-than-ideal conditions. The ability to quickly and accurately deliver emergency medications can be the determining factor in patient survival.

Diagnostic Applications

Veterinary injection syringes play crucial roles in diagnostic procedures, from blood sample collection to fine-needle aspirates for cytological examination. The quality of diagnostic samples often depends on proper veterinary syringe technique, making these animal healthcare tools essential components of veterinary diagnostic capabilities.

Specialized diagnostic applications, such as joint fluid analysis or cerebrospinal fluid collection, require precise veterinary syringe control and often demand specific needle configurations. The ability to collect high-quality samples directly impacts diagnostic accuracy and subsequent treatment decisions.

Quality Standards and Regulatory Considerations

Manufacturing Standards

Veterinary injection syringes must meet stringent manufacturing standards that ensure consistent quality and performance. ISO 7886 standards govern veterinary syringe dimensions, performance characteristics, and safety requirements. These international standards ensure compatibility between veterinary syringes and needles from different manufacturers while maintaining veterinary needle safety and efficacy standards.

Quality control processes in syringe manufacturing include dimensional verification, sterility testing, and performance validation. Each batch of syringes undergoes rigorous testing to ensure they meet specifications for accuracy, durability, and sterility maintenance.

Sterility and Contamination Prevention

Maintaining sterility throughout the manufacturing, storage, and use process represents a critical aspect of veterinary syringe quality. Gamma irradiation, ethylene oxide treatment, and other sterilization methods ensure syringes remain free from microbial contamination until use.

Single-use policies have become standard practice in veterinary medicine, eliminating risks associated with syringe reuse while ensuring optimal performance for each injection. This approach also prevents cross-contamination between patients, a particularly important consideration in livestock operations where disease transmission can have catastrophic consequences.

Best Practices in Veterinary Syringe Use

Proper Handling and Technique

Effective syringe use begins with proper selection based on medication volume, viscosity, and patient characteristics. Pre-injection preparation includes visual inspection of the syringe for damage, verification of medication compatibility, and selection of appropriate needle gauge and length.

Injection technique varies significantly between species and anatomical sites. Proper restraint techniques, anatomical landmark identification, and injection angle considerations all impact both safety and efficacy. Veterinary professionals must maintain proficiency across multiple species and injection sites, each requiring specific technical expertise.

Storage and Inventory Management

Proper storage conditions ensure syringe integrity and sterility maintenance. Temperature control, humidity management, and protection from light exposure all influence syringe performance and shelf life. Inventory rotation systems ensure older stock is used first, preventing expiration-related waste.

Organization systems that segregate syringes by size, application, and species help prevent errors while improving efficiency during busy clinical periods. Clear labeling and accessible storage locations reduce the time required to locate appropriate equipment during emergency situations.

Safety Protocols and Risk Management

Needle-stick injury prevention represents a primary safety concern in veterinary syringe use. Proper disposal techniques, never recapping used needles, and utilizing safety-engineered devices help minimize occupational risks. Training programs ensure all staff understand proper handling techniques and emergency protocols for accidental exposures.

Patient safety considerations include proper injection site selection, appropriate restraint techniques, and post-injection monitoring for adverse reactions. Documentation of injection sites, medications administered, and patient responses provides important medical record information for future reference.

Technological Innovations and Future Developments

Smart Syringe Technologies

Recent technological advances have introduced smart features to veterinary syringes, including dose-measurement systems, injection tracking capabilities, and integrated safety mechanisms. These innovations aim to reduce medication errors while improving documentation and traceability in veterinary treatments.

Digital integration allows for automatic recording of medication administrations, helping maintain accurate medical records while reducing administrative burden on veterinary staff. Some systems include barcode scanning capabilities that verify correct medication and dosing before administration.

Sustainable Design Initiatives

Environmental considerations have influenced modern syringe design, with manufacturers developing more sustainable materials and packaging options. Biodegradable components, reduced plastic content, and recyclable packaging help address environmental concerns while maintaining performance standards.

Refillable syringe systems for specific applications offer alternatives to single-use devices in certain circumstances, though sterility and cross-contamination prevention remain primary considerations in their implementation.

Specialized Application Development

Emerging veterinary specialties have driven development of highly specialized syringe systems. Ophthalmologic applications require ultra-precise micro-syringes, while cardiac interventions demand specialized designs for intracardiac injections. These niche applications push the boundaries of syringe technology while serving critical veterinary needs.

Economic Considerations and Practice Management

Cost-Effectiveness Analysis

While veterinary syringes represent a relatively small component of overall practice expenses, their selection can impact both direct costs and operational efficiency. Higher-quality syringes may carry premium prices but often provide superior performance and reliability that justify the additional investment.

Bulk purchasing strategies can significantly reduce per-unit costs while ensuring adequate inventory levels. However, storage capacity limitations and expiration date management must be balanced against volume discount opportunities.

Impact on Practice Efficiency

Syringe performance directly affects clinical efficiency and patient throughput. Reliable, easy-to-use syringes reduce the time required for medication preparation and administration, allowing veterinary teams to treat more patients effectively. This operational efficiency translates directly into practice profitability and client satisfaction.

Standardization of syringe types across practice locations reduces inventory complexity while ensuring staff familiarity with equipment. This standardization approach also simplifies training programs and reduces the potential for user errors associated with unfamiliar equipment.

Global Perspectives and Market Trends

Regional Variations in Syringe Use

Different regions exhibit varying preferences for syringe types, sizes, and features based on local veterinary practices, animal populations, and economic considerations. Developing regions may favor more basic, cost-effective options, while developed markets increasingly demand advanced safety features and precision capabilities.

Cultural factors also influence syringe selection and use patterns. Traditional veterinary practices in some regions may utilize different injection techniques or prefer specific syringe characteristics based on historical experience and local animal handling methods.

Market Evolution and Future Outlook

The global veterinary syringe market continues evolving in response to changing veterinary practice patterns, regulatory requirements, and technological capabilities. Increasing pet ownership worldwide drives demand for companion animal healthcare tools applications, while growing livestock injection systems operations in developing regions expand large animal syringe markets.

Consolidation among veterinary medical equipment manufacturers has led to increased standardization and quality improvements while potentially reducing innovation in some market segments. However, specialized veterinary injection syringe needs continue driving niche product development and customization opportunities.

Conclusion: The Continuing Evolution of an Essential Tool

Veterinary injection syringes represent far more than simple medical devices—they embody the precision, reliability, and versatility required in modern animal healthcare. From their humble origins as basic medication delivery tools, contemporary veterinary syringes have evolved into sophisticated veterinary medical equipment that enables life-saving treatments across an incredible diversity of animal species.

The ongoing evolution of veterinary injection syringe technology reflects broader trends in veterinary medicine toward increased precision, enhanced veterinary needle safety, and improved efficiency. As veterinary practice continues advancing, these essential animal healthcare tools will undoubtedly continue adapting to meet new challenges and opportunities in animal healthcare.

For veterinary professionals, understanding the capabilities and limitations of different veterinary syringe types remains crucial for optimal patient care. The proper selection and use of veterinary injection syringes directly impacts treatment outcomes, safety, and practice efficiency. As such, these seemingly simple animal healthcare tools deserve recognition as fundamental components of the veterinary medical arsenal.

The future of veterinary syringes lies in continued innovation that addresses emerging challenges while maintaining the reliability and precision that define effective animal healthcare. Whether through advanced materials, smart technologies, or specialized applications, veterinary injection syringes will continue serving as essential tools in the noble mission of animal health and welfare.

In this context, the veterinary injection syringe stands not merely as a medical device, but as a symbol of the veterinary profession’s commitment to precise, compassionate, and effective animal healthcare. Its continued evolution ensures that veterinary professionals will always have the veterinary medical equipment necessary to meet their patients’ healthcare needs, regardless of species, size, or medical complexity.