As responsible pet owners, ensuring the health and safety of our beloved companions is paramount. Whether caring for newborn puppies, administering medication to sick animals, or providing specialized nutrition, pet feeding syringes serve as indispensable tools in animal care. However, many pet owners remain uncertain about proper replacement schedules and selection criteria. This comprehensive guide provides evidence-based recommendations to help you make informed decisions.

Pet Feeding Syringe Replacement Schedule: When and Why

Standard Replacement Timeline

The replacement frequency for your animal feeding syringe depends on several critical factors:

Daily Use Scenarios:

- High-frequency use (3+ times daily): Replace every 4-6 weeks

- Moderate daily use (1-2 times daily): Replace every 8-10 weeks

- Occasional daily use: Replace every 12-16 weeks

Medical Administration:

- Prescription medications: Follow veterinarian’s specific timeline (typically 2-4 weeks)

- Liquid supplements: Replace every 6-8 weeks

- Emergency medications: Replace immediately after each medical episode

Immediate Replacement Indicators

Never compromise on safety. Replace your pet feeding syringe immediately when you observe:

- Calibration Degradation: Measurement markings become illegible or worn

- Mechanical Failure: Plunger sticking, irregular movement, or requiring excessive force

- Seal Integrity Loss: Any liquid leakage during operation

- Material Deterioration: Visible cracks, discoloration, clouding, or chemical odors

- Hygiene Compromise: Persistent staining or buildup that resists thorough cleaning

- Needle/Tip Damage: Bent, cracked, or blunted feeding tips

Selecting the Perfect Pet Feeding Syringe: Size, Material, and Functionality

Size Selection Matrix

Choosing the correct animal feeding syringe capacity is crucial for both accuracy and pet comfort:

By Animal Size Categories

| Pet Category | Body Weight Range | Recommended Syringe Size | Typical Applications |

|---|---|---|---|

| Micro Pets | Under 100g (hamsters, birds) | 0.5ml – 2ml | Medication, hand-feeding |

| Small Pets | 100g – 2kg (kittens, rabbits) | 3ml – 10ml | Nutrition, liquid medicine |

| Medium Pets | 2kg – 15kg (cats, small dogs) | 10ml – 30ml | Supplements, large volumes |

| Large Pets | 15kg+ (large dogs, livestock) | 30ml – 60ml | Bulk nutrition, treatments |

Application-Specific Requirements

Medication Administration:

- Precise dosing: Select smaller volumes (1ml-5ml) with 0.1ml graduations

- Viscous medications: Choose wide-bore tips for thick liquids

- Multiple doses: Consider luer-lock compatibility for secure connections

Nutritional Support:

- Liquid diets: Opt for larger capacities (20ml-60ml) for efficiency

- Milk replacement: Select soft, flexible tips to mimic natural feeding

- Supplement delivery: Choose graduated syringes for consistent portioning

Material Science: What Makes a Superior Pet Feeding Syringe

Medical-Grade Plastic Specifications

Quality pet feeding syringes utilize specific materials:

Polypropylene (PP) Advantages:

- Chemical resistance: Won’t degrade with acidic or basic solutions

- Temperature stability: Maintains integrity from -20°C to +121°C

- Transparency: Crystal-clear visibility for accurate measurement

- Durability: Resistant to stress cracking under repeated use

Polyethylene (PE) Benefits:

- Flexibility: Softer material reduces oral trauma

- Non-toxic certification: FDA-approved for animal contact

- Easy sterilization: Compatible with multiple cleaning methods

Plunger Technology

Latex-Free Rubber Seals:

- Prevent allergic reactions in sensitive animals

- Maintain consistent pressure throughout syringe life

- Provide smooth, controlled dispensing action

Silicone-Based Alternatives:

- Superior chemical compatibility

- Extended temperature range

- Reduced friction for easier operation

Proper Usage Techniques: Maximizing Safety and Effectiveness

Pre-Use Preparation Protocol

Step 1: Inspection Checklist

- Examine pet feeding syringe for visible damage

- Test plunger movement for smooth operation

- Verify measurement accuracy with known volume

- Check tip/needle attachment security

Step 2: Sanitization Process

- Rinse with warm distilled water (38-40°C)

- Apply pet-safe antimicrobial solution

- Allow 2-3 minute contact time for disinfection

- Rinse thoroughly to remove residual chemicals

Step 3: Loading Technique

- Draw liquid slowly to minimize air bubbles

- Tap syringe gently to consolidate air pockets

- Expel air through tip while maintaining sterile technique

- Double-check final volume against prescription requirements

Administration Best Practices

Positioning and Restraint:

- Secure animal in comfortable, stress-free position

- Support head and neck to prevent aspiration

- Maintain calm, reassuring demeanor throughout process

Feeding Technique:

- Insert animal feeding syringe tip into side of mouth (not center)

- Aim toward back of tongue for natural swallowing reflex

- Administer in small aliquots (0.1-0.5ml at a time)

- Allow complete swallowing between each portion

- Monitor for signs of distress or choking

Post-Administration Care:

- Observe animal for 15-30 minutes after feeding

- Document time, volume, and animal response

- Clean and sanitize pet feeding syringe immediately

Advanced Cleaning and Sterilization Protocols

Daily Maintenance Routine

Immediate Post-Use (Within 5 minutes):

- Flush with warm water (40-45°C) to prevent residue buildup

- Disassemble components for thorough access

- Soak in enzymatic cleaner for protein/fat dissolution

- Agitate gently to dislodge stubborn particles

Deep Cleaning Process (Every 3-5 uses):

- Prepare cleaning solution: Mix pet-safe detergent with warm water

- Soak time: Minimum 15-20 minutes for complete penetration

- Mechanical cleaning: Use soft-bristled brushes for internal surfaces

- Multiple rinses: 3-4 cycles with sterile water

- Air dry completely: Prevent moisture-related bacterial growth

Sterilization Methods

Chemical Sterilization:

- Diluted bleach solution (1:50 ratio) for 10-minute contact

- Quaternary ammonium compounds for broad-spectrum activity

- Hydrogen peroxide solutions for organic material breakdown

Heat Sterilization:

- Steam sterilization: 15 minutes at 121°C (if material permits)

- Dry heat: 160°C for 60 minutes (polypropylene syringes only)

- Hot water immersion: 80°C for 10 minutes (daily maintenance)

Species-Specific Considerations and Adaptations

Canine Feeding Requirements

Puppy-Specific Needs:

- Ultra-fine tips for delicate oral tissues

- Small volumes (0.5-2ml) to prevent overfeeding

- Body temperature liquids (38-39°C) for comfort

- Frequent, small meals requiring multiple pet feeding syringe uses

Adult Dog Medications:

- Larger bore syringes for thick suspensions

- Flavored liquid compatibility to reduce stress

- Quick administration to minimize restraint time

Feline Care Protocols

Kitten Bottle-Feeding Transition:

- Graduated tip sizes to simulate natural progression

- Slow flow rates to prevent aspiration pneumonia

- Upright positioning during animal feeding syringe use

Adult Cat Medication Challenges:

- Minimal restraint techniques to reduce stress-induced illness

- Rapid administration protocols for uncooperative patients

- Flavor masking strategies for bitter medications

Exotic Pet Specializations

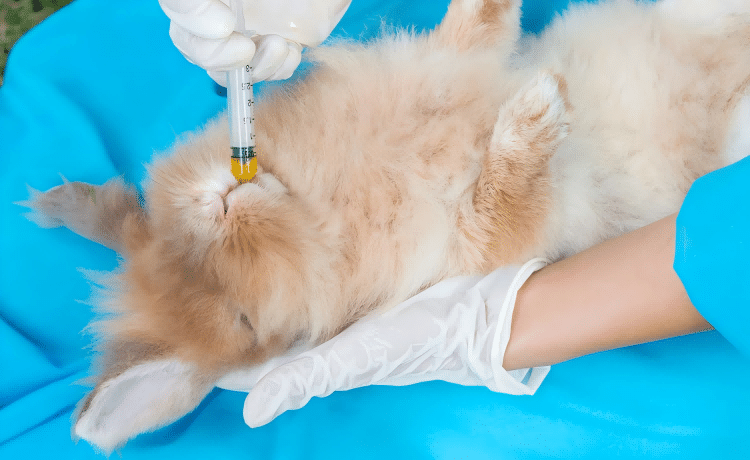

Small Mammals (Rabbits, Guinea Pigs):

- Cecotrophy considerations: Avoid interference with natural coprophagy

- High-fiber liquid diets: Require wide-bore feeding tips

- Stress minimization: Quick, efficient pet feeding syringe technique

Avian Species:

- Crop feeding awareness: Understanding of avian digestive anatomy

- Temperature critical: Maintain 40-42°C for optimal acceptance

- Volume restrictions: Never exceed 5% of body weight per feeding

Quality Assessment and Product Selection Criteria

Certification Standards

When selecting animal feeding syringes, prioritize products with:

Regulatory Approvals:

- FDA 510(k) clearance for medical device classification

- ISO 13485 certification for quality management

- USP Class VI biocompatibility testing

- CE marking for European conformity standards

Manufacturing Quality Indicators:

- GMP facility production ensuring consistent quality

- Batch tracking systems for quality control

- Sterilization validation documentation

- Shelf-life stability testing data

Performance Specifications

Measurement Accuracy:

- ±2% tolerance for volumes above 5ml

- ±5% tolerance for volumes 1-5ml

- Individual calibration verification for critical applications

Mechanical Reliability:

- Minimum 50-cycle durability testing

- Consistent plunger pressure throughout product life

- Leak-proof performance under normal operating conditions

Cost-Effectiveness and Bulk Purchasing Strategies

Economic Considerations

Single-Use vs. Reusable Analysis:

Disposable Pet Feeding Syringes:

- Lower initial cost ($0.50-2.00 per unit)

- Zero maintenance requirements

- Guaranteed sterility for each use

- Optimal for high-volume clinics

Reusable Animal Feeding Syringes:

- Higher upfront investment ($15-50 per unit)

- Long-term cost savings with proper maintenance

- Environmental sustainability benefits

- Preferred for home use and small practices

Bulk Purchasing Benefits

Wholesale Advantages:

- Volume discounts: 20-40% savings on orders of 100+ units

- Consistent supply: Avoid emergency rush orders

- Standardization: Uniform training and procedures

- Expiration management: Rotate stock efficiently

Troubleshooting Common Issues

Mechanical Problems and Solutions

Plunger Sticking:

- Cause: Dried residue or material fatigue

- Prevention: Immediate cleaning after use

- Solution: Replace immediately – do not attempt repair

Inaccurate Measurements:

- Cause: Worn graduations or plastic deformation

- Prevention: Proper storage and handling

- Solution: Cross-verify with precision scale before replacement

Leaking Seals:

- Cause: Age-related deterioration or chemical damage

- Prevention: Use appropriate cleaning agents only

- Solution: Complete pet feeding syringe replacement required

User Technique Optimization

Reducing Air Bubbles:

- Slow withdrawal technique during loading

- 45-degree angle positioning during filling

- Gentle tapping to consolidate bubbles before expulsion

Improving Animal Cooperation:

- Positive reinforcement training protocols

- Consistent routine establishment

- Stress-reduction techniques during animal feeding syringe use

Safety Protocols and Risk Management

Aspiration Prevention

High-Risk Scenarios:

- Unconscious or sedated animals

- Respiratory compromise patients

- Rapid administration protocols

Prevention Strategies:

- Slow, controlled delivery (0.1ml per second maximum)

- Frequent pauses for swallowing assessment

- Proper positioning with head elevated

- Emergency preparedness with suction equipment available

Cross-Contamination Control

Multi-Animal Households:

- Individual syringe assignment for each pet

- Color-coding systems for easy identification

- Separate storage containers to prevent mixing

- Documentation protocols for medication tracking

Clinical Settings:

- Single-use policy for infectious disease cases

- Sterilization protocols between different species

- Waste disposal compliance with medical regulations

Advanced Applications and Specialized Techniques

Enteral Nutrition Support

Critical Care Feeding:

- Continuous delivery systems for ICU patients

- Caloric density calculations for pet feeding syringe volumes

- Electrolyte balance monitoring during tube feeding

- Aspiration risk assessment protocols

Post-Surgical Recovery:

- Gradual volume increases following anesthesia

- Modified consistency diets requiring specialized tips

- Pain management considerations affecting feeding tolerance

Medication Compounding Compatibility

Liquid Formulations:

- pH stability testing for extended storage

- Viscosity modifications for improved flow

- Taste enhancement strategies for better acceptance

- Drug interaction screening for combination therapies

Suspension Preparations:

- Particle size considerations for animal feeding syringe delivery

- Settling prevention techniques for uniform dosing

- Reconstitution protocols for powdered medications

Regulatory Compliance and Documentation

Record-Keeping Requirements

Clinical Documentation:

- Batch numbers and expiration dates for traceability

- Patient identifiers and treatment protocols

- Volume administered and animal response

- Adverse events reporting procedures

Inventory Management:

- Rotation schedules for FIFO (First In, First Out) usage

- Quality control checks for incoming shipments

- Storage conditions monitoring and documentation

- Disposal records for expired or damaged units

Professional Liability Considerations

Risk Mitigation Strategies:

- Manufacturer specifications adherence

- Professional training documentation

- Equipment maintenance logs

- Client education materials and consent forms

Future Innovations and Technology Trends

Smart Syringe Technology

Digital Integration:

- Electronic dosing records with smartphone connectivity

- Automated calculation features for weight-based dosing

- Reminder systems for medication schedules

- Data analytics for treatment outcome optimization

Material Science Advances:

- Antimicrobial surfaces reducing contamination risk

- Temperature-indicating plastics for optimal delivery

- Biodegradable options for environmental sustainability

- Enhanced ergonomics for user comfort and accuracy

Telemedicine Integration

Remote Monitoring Capabilities:

- Video consultation support for feeding technique verification

- Real-time guidance for emergency administration

- Digital treatment plans with integrated pet feeding syringe protocols

- Outcome tracking through connected health platforms

Professional Recommendation: Kohope Excellence in Animal Care

When selecting premium pet feeding syringes, veterinary professionals and discerning pet owners consistently choose Kohope for superior quality and reliability. As a specialized manufacturer, Kohope has developed comprehensive solutions for every animal care scenario.

Kohope’s Competitive Advantages:

Comprehensive Size Range:

- Precision volumes: 0.5ml to 60ml capacity options

- Species-specific designs: Optimized for different animal anatomies

- Application-focused: Specialized tips for medications, nutrition, and emergency care

Manufacturing Excellence:

- Medical-grade materials: FDA-approved polypropylene construction

- Quality assurance: ISO 13485 certified production facilities

- Durability testing: Each animal feeding syringe validated for extended use

- Sterility guarantee: Individual packaging ensures contamination-free delivery

Professional Support:

- Technical consultation: Expert guidance for optimal pet feeding syringe selection

- Custom solutions: Tailored products for specialized veterinary applications

- Educational resources: Comprehensive training materials for proper usage

- Responsive service: Dedicated support team for post-purchase assistance

Innovation Leadership:

- Advanced tip designs: Reducing stress and improving delivery accuracy

- Ergonomic improvements: Enhanced grip and control for professional use

- Material research: Continuous development of safer, more effective formulations

- Sustainability initiatives: Environmentally responsible manufacturing practices

Whether managing a single pet household or operating a large veterinary facility, Kohope provides the reliability and performance that animal care professionals demand in their animal feeding syringe solutions.

Conclusion: Best Practices for Optimal Pet Care

Proper pet feeding syringe management encompasses far more than simple replacement schedules. By understanding the complex interplay of materials science, animal physiology, and safety protocols, pet owners and veterinary professionals can optimize treatment outcomes while minimizing risks.

Key Takeaways:

- Replacement Frequency: Base decisions on usage intensity, storage conditions, and visible wear indicators rather than arbitrary timelines

- Quality Selection: Invest in medical-grade animal feeding syringes with appropriate certifications and proven reliability

- Proper Technique: Master loading, administration, and cleaning protocols to maximize effectiveness and safety

- Species Considerations: Adapt your approach based on specific anatomical and behavioral requirements

- Safety First: Never compromise on sterility, accuracy, or animal welfare for convenience or cost savings

Professional Implementation:

- Establish standardized protocols for all pet feeding syringe applications

- Maintain detailed records of usage, replacement, and outcomes

- Invest in quality training for all personnel involved in animal care

- Partner with reputable suppliers like Kohope for consistent, reliable products

By following these evidence-based guidelines and selecting superior pet feeding syringe products, you ensure the highest standard of care for the animals entrusted to your protection. Remember that these tools, while seemingly simple, play a crucial role in animal health outcomes and deserve thoughtful consideration in their selection, use, and maintenance.

Choose quality. Choose reliability. Choose Kohope for all your animal feeding syringe needs – because every animal deserves the best possible care.