When we slip on a thin medical face mask, few of us pause to consider the remarkably sophisticated medical face mask filtration mechanisms packed into this seemingly simple piece of protective equipment. From materials science to physics, from nanotechnology to fluid dynamics, every detail of a medical face mask represents humanity’s ingenious battle against microscopic pathogens.

Peer at a medical face mask under a microscope, and you’ll discover it’s nothing like the simple “sieve” we might imagine. Instead, what emerges is a three-dimensional labyrinth constructed from millions of ultra-fine fibers, each strand dozens of times thinner than a human hair. These fibers are arranged in what appears random but is actually a meticulously engineered pattern, creating multiple lines of defense at the microscopic scale using various medical face mask filtration mechanisms to trap particles invisible to the naked eye.

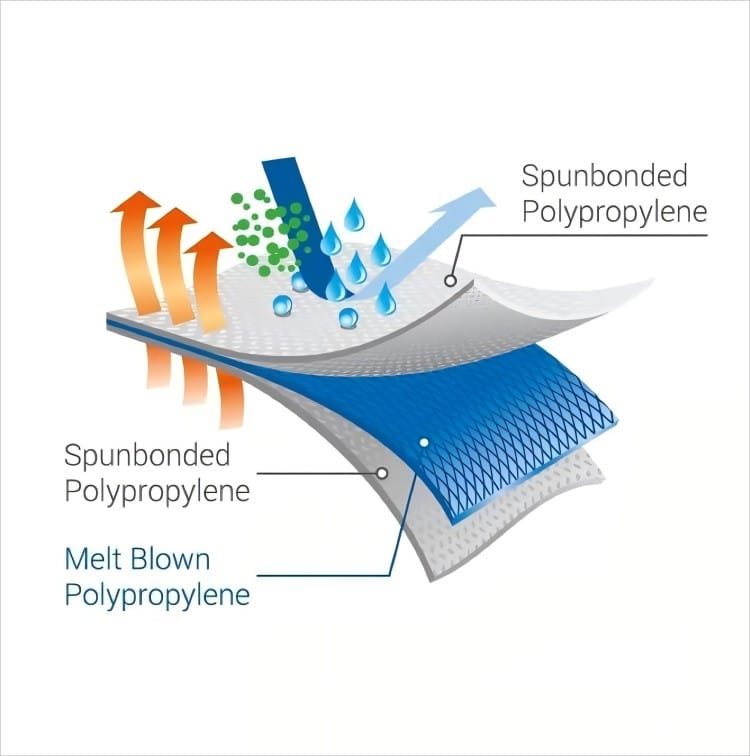

Modern medical face masks typically employ a three-layer design philosophy based on “layered protection.” The outermost layer—what we see directly—is usually made from polypropylene spunbond nonwoven fabric. This material undergoes special hydrophobic treatment, giving its surface powerful water-repelling properties. When droplets hit this layer, they behave like water beads on a lotus leaf, quickly rolling off rather than penetrating through. The fibers in this layer are relatively coarse, typically 10-30 micrometers in diameter, primarily serving to block large liquid droplets and provide mechanical protection for the inner layers.

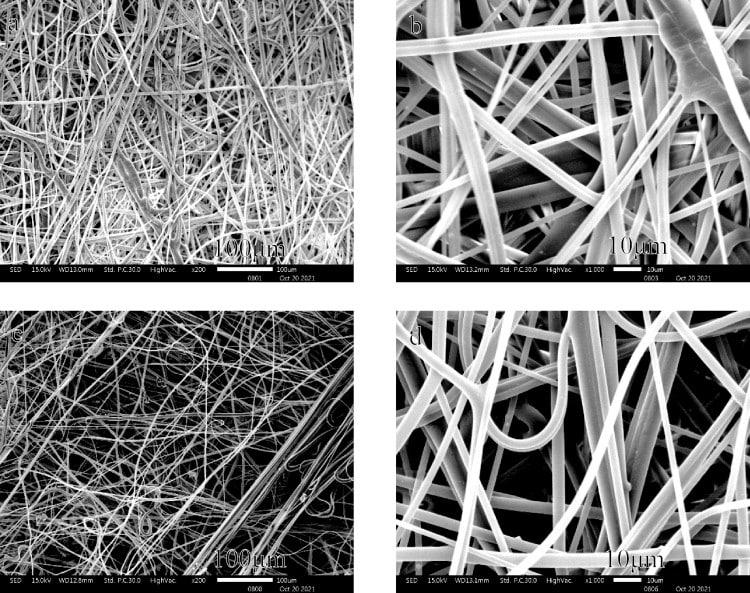

The true filtering powerhouse lies in the middle layer, crafted from meltblown nonwoven fabric—the most technologically sophisticated component of the entire mask. Manufacturing this material requires a specialized technique called the “meltblown process.” In this process, polypropylene material is heated to 280-300 degrees Celsius until completely molten, then extruded through extremely fine nozzles. Simultaneously, high-temperature, high-velocity airstreams blast from both sides of the nozzles, instantly stretching the freshly extruded molten plastic into ultra-fine fibers just 1-5 micrometers in diameter. These fibers rapidly cool and solidify in mid-air before settling onto collection screens to form fluffy nonwoven fabric.

This manufacturing process sounds straightforward, but it demands incredibly precise control. A slight temperature deviation can make fibers too thick or too thin; improper airflow velocity leads to uneven fiber distribution; incorrect cooling rates alter the material’s crystalline structure, affecting final performance. Most critically, electrostatic treatment occurs during this process—high-voltage electric fields charge the fibers, laying the foundation for subsequent electrostatic filtering effects.

The innermost layer sits against our faces, and while its role seems simple, it’s actually crucial. This layer must possess excellent moisture absorption properties, quickly wicking away exhaled water vapor while remaining soft enough for comfortable wear. More importantly, this layer provides secondary filtration, capturing any ultra-fine particles that might penetrate the first two layers.

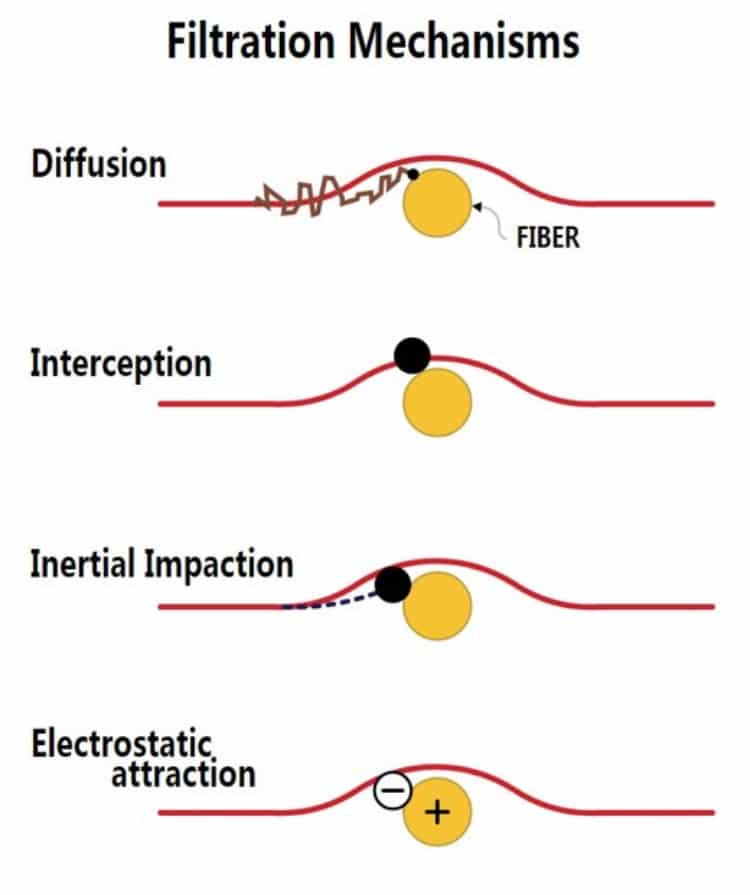

When air containing various particles passes through such a multi-layered structure, a series of complex physical processes unfolds. First comes the inertial impaction effect. As air flows through the fiber network, larger particles (typically greater than 1 micrometer) cannot change direction quickly enough due to their inertia to follow the airstream around fibers—instead, they collide directly with fiber surfaces. Picture a speeding car suddenly encountering a sharp curve; inertia prevents timely turning, causing it to hit the guardrail. This mechanism proves highly effective against pollen, dust, and most bacteria—basically larger particles.

For extremely tiny particles—viruses or nanoscale pollutants—the situation becomes entirely different. These particles are so small they’re influenced by random collisions from surrounding gas molecules, producing a phenomenon called Brownian motion. Imagine pollen grains in water, jostling irregularly due to water molecule impacts. Within mask fibers, these microscopic particles undergo similar diffusive movement, their actual paths far exceeding their straight-line displacement with airflow. This random diffusion dramatically increases their probability of contacting fiber surfaces, and once contact occurs, van der Waals forces and other intermolecular attractions firmly adsorb them onto fibers.

However, the most intriguing and challenging particles are medium-sized ones, roughly 0.1 to 1 micrometer in diameter. They’re neither large enough for effective inertial impaction capture nor small enough to exhibit significant Brownian diffusion. Dealing with these particles relies mainly on two mechanisms: direct interception and electrostatic adsorption.

Direct interception is a purely geometric phenomenon. When particles move with airflow, if their trajectory brings them within one particle radius of a fiber surface, they get directly intercepted. This requires fiber networks with appropriate pore size distribution—not too large for particles to pass through easily, yet not too small to create excessive airflow resistance.

Electrostatic adsorption represents modern high-efficiency medical face mask filtration mechanisms’ secret weapon. During manufacturing, fibers undergo special electrostatic treatment, loading their surfaces with abundant positive and negative charges. These charges create electric fields around fibers, generating attractive forces on particles entering these regions. Fascinatingly, this attraction works not only on oppositely charged particles but also on neutral ones, because electric fields induce dipole moments in neutral particles, creating attractive forces.

The synergistic action of these four medical face mask filtration mechanisms produces a surprising phenomenon: there exists a “most penetrating particle size” range, typically between 0.1 and 0.3 micrometers. Within this range, large-particle mechanisms (inertial impaction and interception) aren’t efficient enough, small-particle mechanisms (diffusion) aren’t strong enough, and electrostatic effects are relatively weak. This explains why international standards typically choose 0.3 micrometers as the test particle size—if masks can effectively filter this most challenging particle size range, they’re even more reliable against other particle sizes.

Based on these scientific principles behind medical face mask filtration mechanisms, countries worldwide have established different mask standards. The American N95 standard requires filtering efficiency of 95% or higher for 0.3-micrometer particles while maintaining acceptable breathing resistance. That 95% figure might not sound perfect, but it’s actually quite remarkable, representing efficiency achieved in the most difficult-to-filter particle size range. For other particle sizes, actual filtering efficiency is often much higher.

Europe’s FFP2 standard is essentially equivalent to American N95 but employs slightly different testing methods. European standards focus more on total inward leakage rates, considering the impact of facial fit. This reflects an important reality: even the best filtering material loses much of its protective effectiveness without proper facial sealing.

China’s KN95 standard has technical requirements basically identical to N95, demonstrating China’s synchronization with international advanced levels in respiratory protection technology. Notably, because Asian and Western facial features differ, Chinese standards specifically consider design requirements suitable for Asian face shapes.

In actual use, factors affecting mask filtering effectiveness extend far beyond the material itself. Wearing technique might be the single most important influence. Even the highest-grade N95 mask, if worn improperly, might provide less actual protection than a correctly worn ordinary medical mask. Any gap between face and mask becomes a “green channel” for particles, because airflow always chooses the path of least resistance.

Electrostatic effect decay represents another crucial factor. As usage time extends, especially in high-humidity environments, electric charges on fiber surfaces gradually dissipate. Research shows that in 85% relative humidity environments, mask electrostatic effects can significantly weaken within hours. This partly explains why masks shouldn’t be reused too many times.

Temperature and humidity changes also affect filtering effectiveness. Low temperatures make fibers more brittle; high temperatures might alter material structure. Humidity not only affects electrostatic effects but can also change fiber geometry and surface properties.

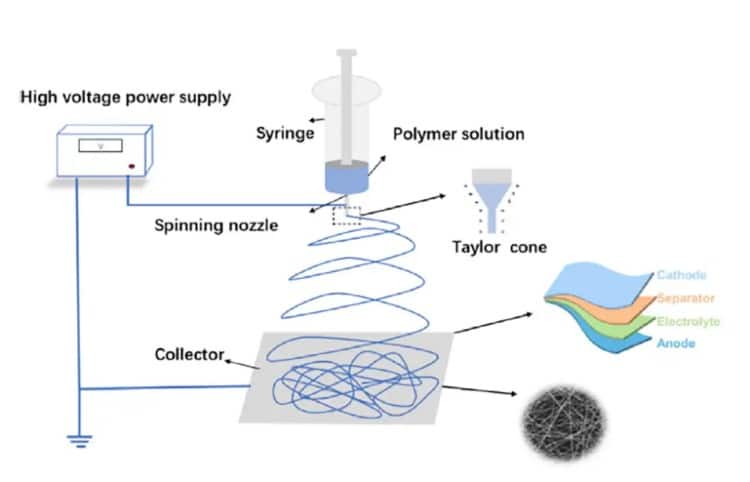

In recent years, advances in nanotechnology and materials science have continuously propelled mask technology forward. Nanofiber applications make further filtering efficiency improvements possible. Nanofibers produced through techniques like electrospinning can achieve diameters of mere tens of nanometers—much finer than traditional meltblown fibers—providing greater specific surface area and higher filtering efficiency.

Functionalization treatment represents another important development direction. By introducing antibacterial and antiviral functional groups onto fiber surfaces, masks can not only physically intercept pathogens but also chemically eliminate them. Some research even explores applications of photocatalytic sterilization and silver ion antibacterial technologies in masks.

Advanced medical face mask filtration mechanisms now incorporate smart technology trends. By integrating micro sensors, future masks might real-time monitor filtering efficiency, usage time, and even detect specific pollutants. When filtering efficiency drops to critical levels, masks could alert users through color changes or other means to replace them promptly.

Environmental concerns are increasingly gaining attention. Traditional disposable masks are mostly made from non-biodegradable polypropylene, creating environmental problems that can’t be ignored after large-scale use. Researchers are exploring biodegradable materials for mask manufacturing or developing safely reusable high-efficiency masks.

The development of medical face mask filtration mechanisms represents humanity’s continuously deepening understanding of the microscopic world. From initial simple cloth coverings to today’s high-tech products based on molecular-level design, every advancement reflects our improved understanding of pathogen transmission mechanisms, materials science principles, and human factors engineering.

Understanding the complex medical face mask filtration mechanisms helps us better harness their protective capabilities. Proper wearing techniques, appropriate replacement frequency, suitable storage conditions—these seemingly detail-oriented issues actually have profound scientific foundations.

Looking ahead, as health protection awareness increases and technology continues advancing, medical masks will inevitably develop toward higher efficiency, greater comfort, smarter features, and better environmental friendliness. As technology continues advancing, these fundamental medical face mask filtration mechanisms will remain the theoretical foundation of mask filtering technology.

Next time we put on a mask, we might consider the rich scientific content packed into this small protective device. From macroscopic engineering design to microscopic molecular interactions, from classical Newtonian mechanics to modern nanotechnology, the medical face mask filtration mechanisms truly embody the profound meaning of “technology transforms life.” In our battle against the invisible microscopic world, it’s precisely this scientific knowledge and technological innovation that constructs a solid protective barrier for us all.

For more related content, please feel free to follow our blog.